- 09

- Oct

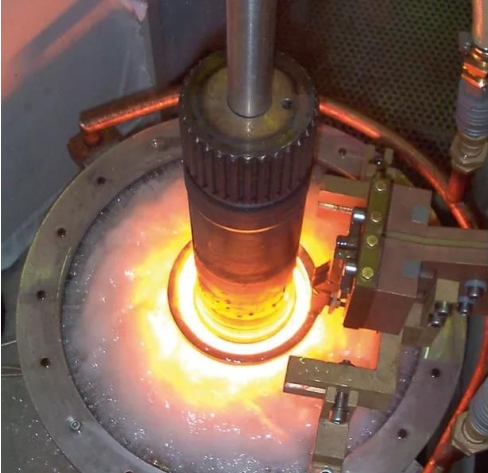

Induction heating surface hardening

Induction heating surface hardening

Operation method: Put the steel part into the inductor to induce current on the surface of the steel part, heat it to the quenching temperature in a very short time, and then spray water to cool it.

Purpose: To improve the surface hardness, wear resistance and fatigue strength of steel parts, and to maintain toughness in the core.

Application points:

1. Mostly used for medium carbon steel and Zhongtang alloy structural steel parts;

2. Due to the skin effect, the high-frequency induction hardening layer is generally 1~2mm, the medium-frequency quenching is generally 3~5mm, and the high-frequency quenching is generally greater than 10mm.

10. Carburizing

Operation method: Put the steel part into the carburizing medium, heat it to 900~950 degrees and keep it warm, so that the surface of the steel part can obtain a certain concentration and depth of carburized layer.

Purpose: To improve the surface hardness, wear resistance and fatigue strength of steel parts, and the core part still maintains toughness.

Application points:

1. Used for low-carbon steel and low-alloy steel parts with a carbon content of 0.15% to 0.25%, generally the depth of the carburized layer.