- 17

- Apr

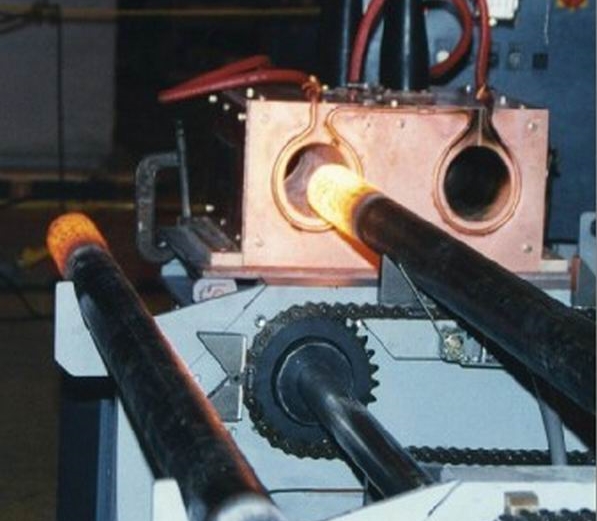

Imishini yokushisa ye-tubing induction

Imishini yokushisa ye-tubing induction

1. Ukwakheka kwe- Ukushisa ukufakelwa device at the end of the tubing

Imishini yokushisa ye-tubing end induction iqukethe isithando somlilo esisezingeni eliphakathi nendawo, ikhabethe le-capacitor, itrolley, i-hydraulic cylinder, iphakethe lamanzi, itroli, i-towline yensimbi engagqwali, ipayipi lamanzi nogesi kanye nekhabethe lamandla wamandla aphakathi nendawo.

Le sethi yemishini inezinqola ezimbili, ngayinye ebekwa kujantshi obekwe phansi, uqhutshwa ngamandla abantu, futhi inedivayisi yokubeka isikulufa. Kunemoto encane kutroli ngayinye. I-chassis yetroli ifakwe nge-angle yensimbi, futhi isondo elincane liyisondo le-V -shaped groove ukuqinisekisa ukunyakaza okushelelayo kwetrololi. I-chassis yemoto ifakwe ophakamisa izibungu, futhi ipuleti elikhulu elingezansi elenziwe nge-epoxy plate ligxunyekwe kulowo ophakamisayo. Ukuqinisekisa ukunyuka nokuwa bushelelezi kwesitezi esikhulu, iphansi elikhulu kanye ne-chassis yemoto kubekwe ojantshi bama-slide abaqondile. Isithando sokufudumeza sokufakwa okuphakathi nendawo sifakwa ekugcineni ngakunye kwepuleti elikhulu eliphansi. I-trolley ingahanjiswa phambili ibuye emuva emuva kwithrekhi egxiliswe enqoleni ngaphansi kwesilinda. Isithando sokufudumeza semvamisa esiphakathi nendawo simiswe kupuleti elincane elincane ngamabhawodi amane. Ipuleti elikhulu elingezansi lingaphakanyiswa noma lehliswe ngophakamisa ngesandla, kanti ipuleti elincane elingezansi lingadlula ocingweni. Induku ihamba ngakwesobunxele nangakwesokudla ukulungisa isikhungo sesithando sokufudumeza esiphakathi nendawo esimweni sokusebenza. Isithando somlilo ngasinye se-IF sinekhabethe le-capacitor. Ikhabethe le-capacitor ligxile kutrololi, futhi ikhabethe le-capacitor lixhunywe nesithando somlilo esisezingeni eliphakathi nendawo ngekhebula elipholile lamanzi. Umkhawulo owodwa wepayipi lamanzi noliwoyela uxhunywe kwimishini esetrololi, kanti omunye umkhawulo uxhunywe ekuhlanganyeleni kwepayipi lokuhlinzeka ngamanzi kuKhabinethi yamandla wamandla amaphakathi nomsele. Ukuxhuma phakathi kwekhabethe le-capacitor kutrololi kanye nesithando sokufudumeza semvamisa esiphakathi nendawo kanye nokuxhumeka kwamanzi nowoyela phakathi kwetroli nomhlabathi kufakwe ngokulandelana kulayini wensimbi ongagqwali.

2, ukwakheka, ukusebenza kanye nenqubo yokusebenza kwepayipi lamafutha lokugcina lokungenisa imishini yokushisa

, Umgomo wokufudumeza kokungeniswa kwendawo yokusebenza ufudunyezwa ukushisa okwenziwe ku-workpiece uqobo ngokungeniswa kwe-electromagnetic, lokhu kunokushisa okushisa okusheshayo, ukushisa okufanayo, ukusebenza kahle kokushisa, kanye nenqubo encane kakhulu yokwenziwa kabusha kwenqubo, njll. imvamisa ukufakwa kwesithando somlilo kusetshenziswa kabanzi ekucutshungulweni kwengcindezi kwezinto zensimbi kanye nenqubo yokushisa yokwelashwa kokushisa. Isithando sokufudumeza sokuvama okuphakathi nendawo sakhiwe ngekhoyili yokungeniswa, ulwelwesi lwesithando somlilo, isakhiwo esisekelekayo nesigobolondo somlilo. Ikhoyili yokungeniswa yenziwa ngeshubhu yethusi enengxenye yesiphambano esingunxande. Ishubhu yethusi ipholile ngamanzi ngesikhathi sokusebenza; isakhiwo sokusekelwa negobolondo lesithando somlilo zenziwe ngezinto ezingezona ezensimbi ezinamandla amakhulu, ukumelana nokushisa okuphezulu nokungashisi.

Le mishini ingu-180kw kanye no-220kw izinhlobo ezimbili zokucaciswa kwesithando somlilo esiteshini se-16 16 esiteshini sokuhlangabezana nokucaciswa okuhlukile kwemikhawulo yepayipi lokushisa. Inombolo 1 No. 1furnace carriage kanye no-2 furnace furnace kanye no-180kw ngokulandelana u-220kw, No. Ibanga lesikhungo semifino emibili yokungeniswa kwe-IF kutrololi ngayinye yi-2 mm kanti isikhungo singama-3 mm ngenhla komhlaba. Onke la mafutha amane anekhabethe lawo lamandla amaphakathi amaphakathi nekhabethe le-capacitor. Iziko lokungeniswa le-4 IF linobukhulu obufanayo nezindawo ezihlanganayo zokuqinisekisa ukuthi isithando somlilo se-IF singashintshwa ngokushesha. ,

I-3, imingcele yezobuchwepheshe yesithando sokufudumeza semvamisa esiphakathi sokushisa okuphelile kwepayipi likawoyela

| Inqola engu-1 | Inqola engu-2 | Amazwi

|

|||

| Cha. 1 isithando somlilo | Akukho 2 isithando somlilo | Cha. 3 isithando somlilo | No. 4 isithando somlilo | ||

| Amandla (kw) | 180 | 220 | 180 | 220, | |

| Imvamisa (khz) | 1.0 | 2.5 | 1.0 | 2.5 | |

| Ukushisa okushisayo (° C) | Ukushisa kwamakamelo ~ 750 | 700to1250 ± 10 | 450 ~ 850 | 800to1250 ± 10 | |

| Ukupholisa ivolumu yamanzi (m3 / h) | 15 | 15 | 15 | 15 | Ukusakazwa kwangaphandle kwamanzi |

| Ukupholisa ingcindezi yamanzi (Mpa) | 0.1to0.4 | 0.1 kuye ku-0.4 | 0.1 kuye ku-0.4 | 0.1 kuye ku-0.4 | |

4, ukuphela kwemoto yokufudumeza ishubhu

I-trolley iqukethe i-chassis yensimbi engeli enamasondo amane ashubile namapaneli amabili aphezulu e-epoxy aphezulu (amapuleti kasilika). Ipuleti elingenhla liyipuleti elincane elincane elinobukhulu obungu-20 mm, kanti ipuleti elingezansi liyipuleti elikhulu elingezansi elinobukhulu obungu-25 mm. Ipuleti elincane elisezansi ligxunyekwe kushaft eslayidayo, kanti ishibhini elislayidayo lilungiswe kupuleti elikhulu elingezansi. Ingxenye engezansi kwepuleti elincane elincane inikezwa ngenathi, futhi isikulufa esijikelezayo singahambisa ipuleti elincane elincane ngokuhamba kwesikhathi. Ipuleti elikhulu laphansi ligxiliswe kulifter wezibungu obekwe ku-chassis wenqola futhi ubekwe ngojantshi abane bomugqa wesilayidi. I-lifter ilawula ipuleti elikhulu elisezansi ukuhambisa phezulu naphansi, kuthi ipuleti elincane elincane lihle liye phezulu naphansi, ukuze isikhungo senzwa silungiswe njengoba kudingeka. Ubakaki wensimbi ongagqwali wokulungisa uchungechunge lokuhudula unamathiselwe ohlangothini olungemuva lwephaneli elingezansi, futhi iketanga lokuhudula lilungiswa ekugcineni okungenhla kwebakaki. Isisekelo setrololi siboshelwe ngesisekelo sokwesekwa esixhunywe kusilinda kawoyela, futhi ngaphansi kwesenzo sikasilinda kawoyela, inqola ingaya phambili nasemuva eceleni kwethrekhi. Ngale ndlela, isithando somlilo esishisayo semvamisa esiphakathi nendawo esibekwe emphemeni ongaphezulu singalungisa isikhundla esiqondisweni sezinhlangothi ezintathu njengoba kudingeka. Iminyakazo yokusika phezulu naphansi nesobunxele nangakwesokudla iyenziwa ngesandla, ukunyakaza kwangaphambili nangemuva kududulwa yisilinda, ukushaywa ngamandla kulawulwa yiswishi esiseduze, nobude bohlangothi bungakhonjiswa esikalini esinqunyelwe enqoleni. ,

5, ukuphela kwesilinda sokushisa se-tubing

I-bore ingu- φ 63 mm kuthi ukushaywa okuphezulu kube ngu-600 mm. I-tubing nezinsiza zayo zikhethwe kwi-Guangzhou Agate Company. Isilinda sime ebusweni benqola. Ipayipi likawoyela lixhunywe emapayipini kawoyela wokufaka nawokukhipha emseleni ngochungechunge lokuhudula.

Iqembu lesikhwama samanzi

Iqembu lesikhwama samanzi lisemuva nasemaceleni omabili etroli. Umsebenzi wawo ukuhambisa nokuqoqa amanzi apholisayo emafutheni amabili wokushisa wokungenisa amaphakathi kanye namakhabethe amabili we-capacitor kutroli. Amanzi apholisayo wesithando sokushisa sokungenisa esivamile esiphakathi nendawo aqhutshelwa ezithandweni zombili ngepompo lamanzi nangohlukanisi wamanzi weqembu elikhulu lesikhwama samanzi. Ngemuva kokuphuma kwesithando somlilo, singena kumqoqi wamanzi weqembu elikhulu lesikhwama samanzi, bese sidlula lapho kuthunyelwa khona amanzi kanye nepayipi. Ekugcineni, ibuyela echibini elijikelezayo. Ngeyeluphu evulekile. Igeji yengcindezi yokuxhumana kagesi ifakwa kusihlukanisi samanzi esithandweni ngasinye sokushisa sokushisa esiphakathi nendawo. Lapho ingcindezi yamanzi ingaphansi kwengcindezi yokusebenza, isithando somlilo sicinywa ngokuzenzekelayo, futhi okokusebenza ngeke kulimale ngenxa yokushoda kwamanzi kwekhoyili. Amanzi okupholisa ekhabethe le-capacitor avela emanzini athambile weyunithi yokupholisa, bese angena kumakhabethe amabili ama-capacitor ngesihlukanisi samanzi seqembu elincane lamaphakethe amanzi, bese egeleza abuyele kumqoqi wamanzi weqembu elincane lamaphakethe wamanzi, futhi ekugcineni ibuyela kuyunithi yokupholisa. Kuyindophi evaliwe. Ukungena nokuphuma kwamaphakethe amabili wamanzi kuxhunywe ngokulandelana emachwebeni okungena nangaphandle emseleni ngokusebenzisa amapayipi akuchungechunge lokuhudula.

Onke amanzi anamandla afakwa ama-valve ezinhlanganisweni zepayipi lamanzi emseleni.

6, ukuphela kwe-trolley yokushisa kwe-tubing

I-trolley ingumzimba oyinhloko womthwalo, futhi okokusebenza okuyinhloko kufakwe kutroli. Usayizi wetrololi ungama-2700 * 1900 mm 2 kanti ubuso betroli bucishe bube yi-366 mm ngaphezulu komhlaba. I-trolley iqhutshwa ngabantu kanti nesifo sohlangothi asikho ngaphansi kuka-2800mm. Ngemuva kokuthi itrolley isendaweni, izikulufo ezine ziyavulwa ukubeka itrolley. ,

7, ukuphela kokushisa kwe-tubing kusethwe ngensimbi engagqwali ye-towline

Ukuze kuqinisekiswe ukuvumelanisa nokuphepha kwepayipi ekuhambeni kwetrololi kanye netrolley, yonke imibhobho esetrolini kanye nokuxhuma komhlaba (kufaka phakathi ipayipi le-hydraulic) kuxhunywe ngochungechunge lokuhudula, ukuphela komsele kulungisiwe end, futhi ukuphela kwetroli kungukuphela kokuhamba. Umsele – i-trailer yensimbi engagqwali ye-towline yi-TL125 III -300 * 350.

Ikhebula elipholile lamanzi phakathi kwekhabethe le-capacitor ku-trolley kanye nesithando sokufudumeza semvamisa esiphakathi naso sixhunywe ngochungechunge lokuhudula. Ukuphela kwekhabethe le-capacitor kungukugcina okuhleliwe, futhi ukuphela kwesisindo esiphakathi nendawo sokushisa kwesiphetho kungukuphela kokuhamba. Ikhabethe le-capacitor – imvamisa emaphakathi yokufakwa kwesithando somlilo insimbi engagqwali imininingwane ye-towline yi-TL95 III -150 * 250. Ngasikhathi sinye, ipayipi lamanzi lokupholisa elingena futhi liphume esithandweni sokushisa sokungenisa esimvamisa esiphakathi esikhwameni esikhulu samanzi nalo lifakiwe kuketanga lokuhudula.

8, ukufakwa kwamatayipi ekugcineni ukufudumeza nokugcinwa

1. Ngaphambi kokufaka esikhundleni sesithando sokufudumeza sokuvama okuphakathi nendawo, misa amandla bese umisa amanzi ngaphambi kokususa umnenke wentambo opholile ngamanzi.

Shintsha ngokushesha ukuhlangana phakathi kwebhawodi nepayipi lamanzi. Ngemuva kokufakwa kwesithando somlilo, hlola ukuvuza kwamanzi kuqala, bese uqinisekisa ukuthi ilunga alivuzi amanzi ngaphambi kokuba linikwe amandla;

2, imvamisa hlola iketango lokuhudula ukuthola amaketanga anamathele noma alahle phansi;

3, gcina ichibi elijikelezayo lihlanzekile futhi lingenayo imfucumfucu, ukuze kuvinjelwe imfucumfucu ukungena epayipini futhi ibangele ukuvimba.

Izinto ezingahleliwe

Isitifiketi sokufaneleka komkhiqizo;

Uhlu lokuhlinzekwa komkhiqizo;

Uhlu lokupakisha;

Incwadi Yokufundisa;

Uhlelo lukagesi nemiyalo;

Imidwebo yokunikezwa okungahleliwe:

Umsele wepayipi;

Umdwebo ojwayelekile womshini wokushisa;

Isakhiwo samandla nesithando somlilo.