- 31

- Jan

How to quench the surface of the axle

How to quench the surface of the axle

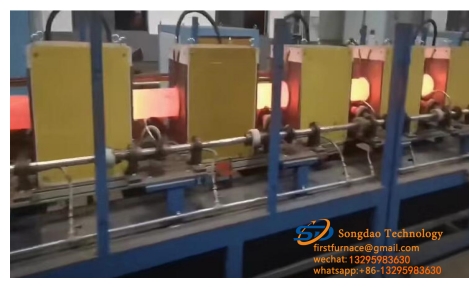

Selection of Axle Surface Strengthening Process For most axle parts, surface quenching after medium frequency induction heating is usually used to improve their service life. The motor axle and the locomotive axle are a kind of mandrel that transmits power and supports, while the vehicle axle is a kind of mandrel that does not transmit power but only supports, and mainly bears bending or bending fatigue loads.

Statistics show that most types of shafts fail due to fatigue fracture and fretting wear. In order to avoid brittle fracture and meet the requirements of the strength and toughness of the axle, the axle is often quenched and tempered or normalized. However, due to the poor performance of fatigue and fretting wear, the service life is not reached.

Practice has shown that, on the basis of quenching and tempering or normalizing, the surface axle induction quenching and tempering quenching treatment can be applied to extend the service life exponentially. Therefore, this is an important process method to improve the service life of the axle.

Akslens overfladeforstærkning vedtager generelt hovedsageligt den mellemfrekvente induktionssluknings- og slukningsopvarmningsprocessen, og den er fuldstændig egnet til opvarmningsdybden af akseloverfladen. , Overfladeinduktionshærdning er meget effektiv til at forbedre bøjnings- eller vridningstræthedsstyrken af akslen, hvilket reducerer følsomheden over for hak og spændingskoncentration. Efter induktionshærdning af akselinduktionskøle- og tempereringsovnen, på grund af kernens høje effektive sejhed og plasticitet, tillades det hærdede lag at have højere hårdhed for at opretholde høj slidstyrke, styrke og resterende trykspænding og give fuldt spil til materialets træthedsmodstand. potentiel.