- 30

- Oct

Nruam casting tundish molten steel induction cua sov khoom

Nruam casting tundish molten steel induction cua sov khoom

1 Txheej txheem cej luam

Tundish molten steel induction cua sov cov cuab yeej siv tshuab yog tsim los nrog kev nce qib ntawm kev siv tshuab nruam nruam, kev txhim kho cov kev xav tau ntawm steel zoo, xav tau kev txuag hluav taws xob thiab kev txo qis, thiab kev sib txuam ntawm sab nraud refining thiab nruam casting txheej txheem. Cov qib steel sib txawv muaj cov kev xav tau sib txawv ntawm AT ntawm molten steel superheat. Rau cov phaj tuab, txhawm rau txo cov kab nrib pleb thiab qhov chaw xoob, AT yuav tsum qis (5 ~ 200T); rau cov ntawv txias-dov nyias, qhov saum npoo yuav tsum muaj qhov zoo. Siab (15 ~ 300 ℃). Txawm li cas los xij, molten steel superheat yuav tsum tau ruaj khov nyob rau hauv ib qho chaw kom txo tau qhov kev hloov pauv. Qhov no yog ib qho tsim nyog los xyuas kom meej qhov kev vam meej ntawm kev nruam casting ntau lawm, tiv thaiv nozzle blockage los yog tiv thaiv kev sib tsoo, thiab xyuas kom meej qhov zoo ntawm cam khwb cia slabs. Kev txhim kho ntawm cov cua sov ua haujlwm ntawm tundish ua rau nws muaj peev xwm tswj tau lub superheat ntawm molten steel stably. Qhov kub ntawm cov hlau molten ntawm txawv ladle fluctuates, uas muaj kev cuam tshuam tsis zoo rau cov txheej txheem nruam casting, thiab cov cua sov ntawm tundish tuaj yeem them rau nws rau qee yam. Txawm li cas los xij, nws yuav tsum tau taw qhia tias kev tswj xyuas qhov ruaj khov molten steel superheat feem ntau yog nyob ntawm qhov ntsuas kub kom zoo thiab kev hloov kho tom qab tapping, thiab cov cua kub tundish tsuas tuaj yeem ua lub luag haujlwm ntxiv. Txawm li cas los xij, cov cua sov thiab tswj cov hlau molten hauv tundish tseem tau txais kev saib xyuas los ntawm cov zej zog metallurgical. Qee lub tebchaws sawv cev los ntawm Nyij Pooj, Tebchaws Meskas, Tebchaws Askiv, thiab Fabkis tau ua tiav kev tshawb fawb txog tundish molten steel cua sov tshuab los ntawm xyoo 1970 txog rau xyoo 1980. Nyiv lub tuam txhab Kawasaki thawj zaug tau tsim thiab tau txais daim ntawv pov thawj Nyij Pooj thaum ntxov li xyoo 1982. Tam sim no, lub tshuab hluav taws xob tundish molten steel tau ua tiav los yog hauv kev loj hlob feem ntau siv cov txheej txheem cua sov lub cev. Hauv cov txheej txheem cua sov ntawm lub cev, lub zog hluav taws xob yog siv los ua qhov cua sov thiab hloov pauv raws li lub zog hluav taws xob. Cov txheej txheem sib txawv tuaj yeem muab faib ua: cov khoom siv hluav taws xob hluav taws xob induction cua sov, plasma cua sov, electroslag cua sov thiab DC ceramic cua sov tshuab.

Tundish induction cua sov cov cuab yeej muaj cov yam ntxwv hauv qab no:

(1) Cov cua kub ceev ceev thiab hluav taws xob hluav taws xob ua haujlwm siab;

(2) Qee hom kuj muaj qee yam electromagnetic stirring effect, uas yog qhov tsim nyog rau kev tshem tawm cov kev suav nrog;

(3) Cov txheej txheem kub yog ib qho yooj yim los tswj, thiab qhov tseem ceeb tshaj plaws yog kom tswj tau qhov superheat ntawm cov hlau molten;

(4) Lub zog cua sov yog txwv los ntawm qhov tob ntawm tundish kua theem. Tsuas yog thaum cov hlau molten nyob rau hauv lub tundish accumulates mus rau ib tug tej yam qhov tob, lub cua sov yuav mus smoothly.

Muaj ntau ntau hom tundish induction cua sov khoom siv:

(1) Raws li hom inductor, nws tuaj yeem muab faib ua coreless induction cua sov khoom thiab cored induction cua sov khoom;

(2) Raws li cov qauv ntawm cov inductor, nws tuaj yeem muab faib ua ntau hom kev ua txhaum thiab hom qhov (groove, molten trench) induction cua sov khoom;

(3) Raws li qhov cua sov, nws tuaj yeem muab faib ua cov cua sov hauv zos thiab tag nrho cov cua sov.

2 Nruam casting tundish molten steel electromagnetic induction cua sov khoom siv

2. 1 Tundish electromagnetic induction cua sov khoom siv nrog kab rov tav nruam casting tshuab

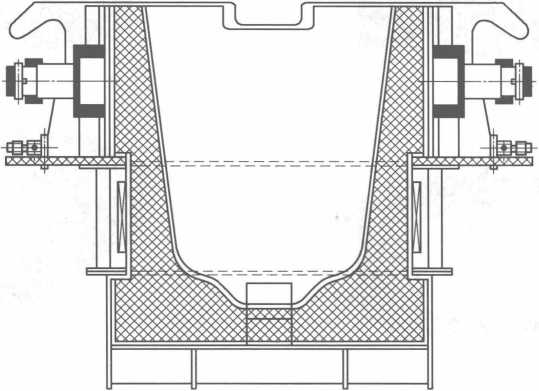

Lub tundish electromagnetic induction cua sov cov cuab yeej txuam nrog kab rov tav nruam casting tshuab yog qhia nyob rau hauv daim duab 10-7.

Kev tsim cov txheej txheem ntawm cov nroj tsuag stainless hlau yog tam sim no piav qhia.

Daim duab 10-7 Tundish electromagnetic induction cua sov khoom siv nrog kab rov tav nruam casting tshuab

Tom qab txhua yam ntawm stainless hlau yog batched, lawv tau loaded rau hauv peb 5t induction furnaces los ntawm lub tank pub nrog cranes. Tom qab cov seem hlau yog melted mus rau qhov yuav tsum tau kub (kwv yees li 1650 ° C), cov hlau molten nyob rau hauv lub induction rauv yog poured rau hauv lub ladle, thiab ces siv lub tsheb pours lub molten steel rau hauv lub 8t AOD rauv, qhov twg nws undergoes decarburization, slagging, dephosphorization thiab sulfur tshem tawm, thiab kho cov alloy muaj pes tsawg leeg (feem ntau yog Cr, Ni), thiab ces molten steel (qhov muaj pes tsawg leeg thiab kub raws li qhov yuav tsum tau) Muab cov hlau molten nyob rau hauv lub ladle rau hauv lub ladle thiab siv lub crane los ncuav. molten hlau nyob rau hauv lub ladle rau hauv lub ladle ntawm 8t electromagnetic induction cua sov khoom. Cov kua stainless hlau rhuab los ntawm kev txuag hluav taws xob yog kos thiab muab pov rau hauv ib puag ncig bar los ntawm kab rov tav nruam casting tshuab thiab thaum kawg thawb mus rau hauv lub txaj txias los ntawm kev sib sau thiab shearing. .

Tom qab txhua yam ntawm stainless hlau yog batched, lawv tau loaded rau hauv peb 5t induction furnaces los ntawm lub tank pub nrog cranes. Tom qab cov seem hlau yog melted mus rau qhov yuav tsum tau kub (kwv yees li 1650 ° C), cov hlau molten nyob rau hauv lub induction rauv yog poured rau hauv lub ladle, thiab ces siv lub tsheb pours lub molten steel rau hauv lub 8t AOD rauv, qhov twg nws undergoes decarburization, slagging, dephosphorization thiab sulfur tshem tawm, thiab kho cov alloy muaj pes tsawg leeg (feem ntau yog Cr, Ni), thiab ces molten steel (qhov muaj pes tsawg leeg thiab kub raws li qhov yuav tsum tau) Muab cov hlau molten nyob rau hauv lub ladle rau hauv lub ladle thiab siv lub crane los ncuav. molten hlau nyob rau hauv lub ladle rau hauv lub ladle ntawm 8t electromagnetic induction cua sov khoom. Cov kua stainless hlau rhuab los ntawm kev txuag hluav taws xob yog kos thiab muab pov rau hauv ib puag ncig bar los ntawm kab rov tav nruam casting tshuab thiab thaum kawg thawb mus rau hauv lub txaj txias los ntawm kev sib sau thiab shearing. .

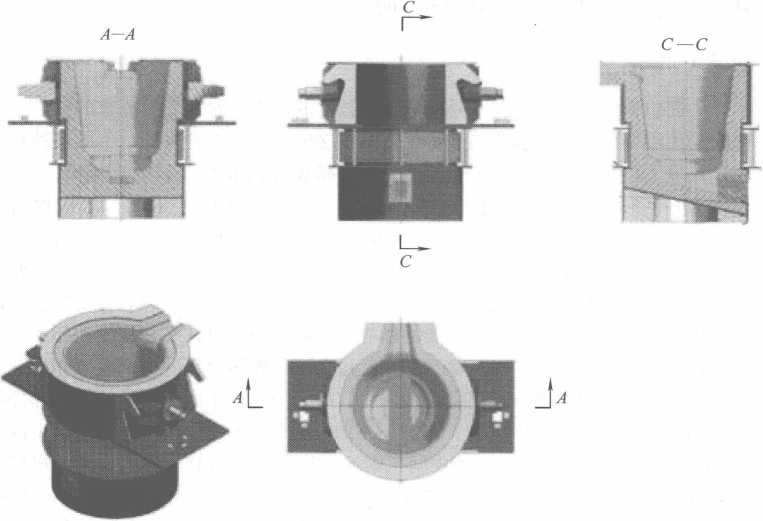

Lub cev khoom ntawm 8t electromagnetic induction cua sov ladle yog qhia hauv daim duab 10-8.

8t thiab 14t tundish electromagnetic induction cua sov cov cuab yeej, tundish induction cua sov cov cuab yeej tuaj yeem tswj tau qhov kub thiab txias ntawm cov hlau molten (qhov kev ua yuam kev tsuas yog ± 5 ~ 6 ℃), yog li ua kom cov khoom zoo ntawm cov hlau. Tsis tas li ntawd, lub sijhawm hloov kho qhov kub thiab txias ntawm tundish kuj tuaj yeem tsim nyog txuas ntxiv, uas qhia txog cov txiaj ntsig zoo ntawm cov khoom siv cua sov induction.

2. 2 Tundish ntaus ntawv ntawm induction cua sov khoom ntawm arc nruam casting tshuab

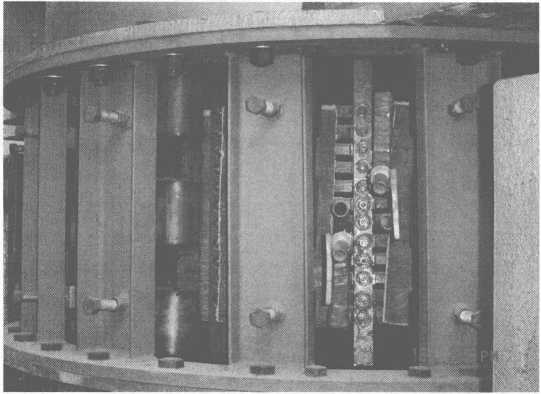

Cov cuab yeej tundish ntawm cov khoom siv cua sov induction ntawm lub tshuab arc nruam casting yog qhia hauv daim duab 10-9.

Tom qab lub arc billet nruam caster txais cov khoom siv hluav taws xob induction cua sov tundish, tapping kub tuaj yeem txo qis (piv txwv li, nws tuaj yeem ua tau.

Daim duab 10-9 Tundish ntaus ntawv ntawm induction cua sov khoom ntawm arc nruam casting tshuab

Los ntawm 1700 ° C mus rau 1650 ° C), qhov no tsis tsuas yog pab txhim kho lub neej ntawm steelmaking rauv hauv ob sab phlu (converter, hluav taws xob arc rauv los yog induction rauv), tab sis kuj stabilizes kub ntawm molten hlau nyob rau hauv nruam casting thiab guarantees qhov zoo ntawm nruam. casting billets.

Raws li cov lus qhia saum toj no, nws tuaj yeem txiav txim siab tias qhov nruam nruam casting tundish magnetic induction cua sov cov cuab yeej yog lub zog txuag hluav taws xob tshiab thiab ib puag ncig-phooj ywg. Kev saws me nyuam ntawm cov cuab yeej no yog ib qho kev hloov kho thev naus laus zis zoo tshaj plaws rau kev lag luam metallurgical, thiab nws tsim nyog rau kev nce qib thiab siv.

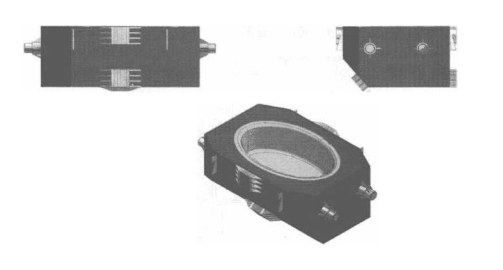

Daim duab 10-10 qhia txog 16t tundish electromagnetic induction cua sov khoom.

Daim duab 10-10 16t tundish electromagnetic induction cua sov khoom

Daim duab 10-11 yog daim duab schematic ntawm tundish ntawm 14t induction cua sov khoom.

Daim duab 10-11 Schematic daim duab ntawm tundish ntawm 14t induction cua sov khoom