- 14

- Apr

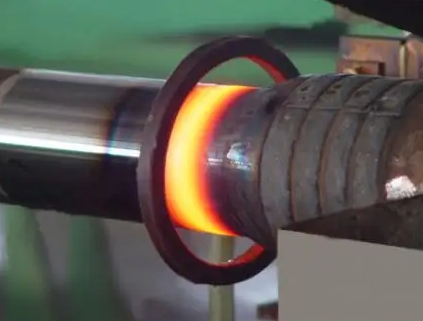

Analysis of heat treatment process of steel spring chuck using high frequency quenching equipment

Analysis of heat treatment process of steel spring chuck using Hochfrequenz-Abschreckgeräte

The spring chuck is widely used in the turning and production of bearing rings. The ring is positioned by its expansion and tightening effect, and it is required to have good plasticity and toughness. In order to facilitate production and management, bearing enterprises generally do not use spring steel, and often use GCr15 steel instead. Because GCr15 steel does not have good plasticity and toughness, it often causes a large number of broken collets in production, which affects the normal production. The failure mode of GCr15 steel collets is mainly early fracture, and the fracture part is mainly the neck. , therefore, it is required to have high hardness and wear resistance, high plasticity. Induction heat treatment of high frequency quenching equipment can completely meet the requirements of the collet chuck.

1) Induction heat treatment process GCr15 steel spring chuck dimensions: head diameter 60mm, tail diameter 52mm, total length 60mm. The high-frequency quenching furnace is used for preheating heat treatment at 500-550 °C, and then heat treatment at 845 °C. During operation, the head is first heated for 5 minutes, and then the whole is heated for 10 minutes. After the whole oil is cooled, it is transferred to 280- Incubate in nitrate at 300°C for 90min, and temper in nitrate at 160°C for 2h.

2) The hardness of GCr15 steel spring collet after being quenched by high frequency quenching furnace is about 10HRC lower than that of conventional quenching, but its service life is increased by 1-1.67 times.