- 14

- Apr

Kev tshuaj xyuas cov txheej txheem kev kho cua sov ntawm steel caij nplooj ntoos hlav chuck siv cov khoom siv quenching siab

Kev soj ntsuam ntawm kev kho cua sov txheej txheem ntawm steel caij nplooj ntoos hlav chuck siv cov khoom siv hluav taws xob ntau zaus

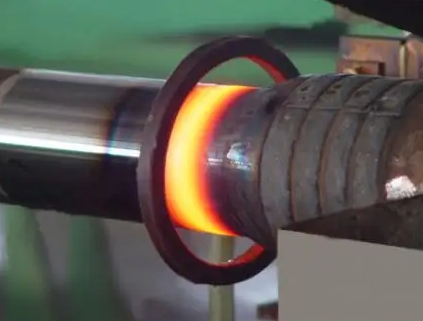

Lub caij nplooj ntoos hlav chuck yog siv dav hauv kev tig thiab tsim cov kabmob rings. Lub nplhaib yog positioned los ntawm nws cov expansion thiab zawm nyhuv, thiab nws yuav tsum muaj zoo plasticity thiab toughness. Txhawm rau pab txhawb kev tsim khoom thiab kev tswj hwm, cov tuam txhab lag luam feem ntau tsis siv lub caij nplooj ntoo hlav steel, thiab feem ntau siv GCr15 steel hloov. Vim tias GCr15 steel tsis muaj cov yas zoo thiab cov tawv tawv, nws feem ntau ua rau cov khoom tawg ntau hauv kev tsim khoom, uas cuam tshuam rau cov khoom qub. Hom tsis ua haujlwm ntawm GCr15 steel collets feem ntau yog pob txha tawg thaum ntxov, thiab qhov tawg feem ntau yog lub caj dab. Yog li ntawd, nws yuav tsum muaj siab hardness thiab hnav tsis kam, siab plasticity. Kev kho cua sov induction ntawm cov khoom siv quenching siab tuaj yeem ua tau raws li qhov yuav tsum tau ua ntawm collet chuck.

1) Induction cua sov txheej txheem GCr15 steel caij nplooj ntoos hlav chuck qhov ntev: lub taub hau txoj kab uas hla 60 hli, tus Tsov tus tw txoj kab uas hla 52 hli, tag nrho ntev 60 hli. Lub tshuab hluav taws xob ntau zaus quenching yog siv rau kev kho cua sov ua ntej ntawm 500-550 ° C, thiab tom qab ntawd kho cua sov ntawm 845 ° C. Thaum lub sij hawm ua hauj lwm, lub taub hau yog thawj rhuab rau 5 feeb, thiab ces tag nrho yog rhuab rau 10 feeb. Tom qab tag nrho cov roj txias, nws raug xa mus rau 280- Incubate nyob rau hauv nitrate ntawm 300 ° C rau 90min, thiab temper nyob rau hauv nitrate ntawm 160 ° C rau 2h.

2) Lub hardness ntawm GCr15 steel caij nplooj ntoos hlav collet tom qab quenched los ntawm high zaus quenching rauv yog hais txog 10HRC qis dua li cov pa quenching, tab sis nws cov kev pab cuam lub neej yog nce los ntawm 1-1.67 zaug.