- 12

- Feb

Yadda za a gina tubalin refractory na tukunyar jirgi?

How to build the refractory bricks of tukunyar jirgi?

1. Ana aiwatar da matakan ginin daidai da ka’idar daga kasa zuwa sama kuma daga ciki zuwa waje. Ƙananan ɓangaren ganga na sama da farantin harshen wuta na convection tube an zuba daga sama zuwa kasa.

2. bangon tanderun yana da buƙatun buƙatun iska, da kuma cikar haɗin toka: tubalin ja ba su da ƙasa da 85%; tubalin da ba su da ƙasa da 90%. Ana amfani da hanyar matsi don ginin bulo na ja, kuma ana amfani da hanyar gogewa don ginin bulo mai jujjuyawa.

3. Masonry of furnace bottom:

(1) Kafin a aza kasan tanderun, sai a daidaita harsashin ginin, sannan a fara gina katangar madaidaiciya da ke kewaye da tanderun da ke kusa da tanderun, kuma tsayin ya kamata ya zama kusan sama da saman kasan tanderun. Sa’an nan kuma yi alama a kwance na ƙasan tanderun (a cikin yanayin masonry mai yawa, tare da adadin yadudduka) a kan madaidaiciyar bango kafin a iya gina ginin tanderun.

(2) Lokacin da kasan tanderun ya ƙunshi nau’i-nau’i masu yawa na tubalin, aikin ginin ya kamata a yi shi da shi tare da Layer Layer, tare da babba da ƙananan yadudduka da nau’in tubalin guda ɗaya, kuma tsayin ɓangarorin mafi yawan tubalin saman. perpendicular zuwa kwarara shugabanci na slag ko gas.

(3) A cikin wurare masu zafi mai zafi da tanderun wuta wanda sau da yawa ya kamata a sake gyarawa, ya kamata a bar tazarar fadadawa a wurin hulɗar da ke tsakanin kasan tanderun da bango madaidaici, kuma igiyar asbestos ko pad asbestos board ya kamata a saka a cikin rata.

4. Masonry na toka guga (ciki har da bango mai karkata):

(1) Before building the ash bucket, first find out the horizontal centerline according to the drawings, and use the horizontal center line to find the longitudinal centerline of each ash bucket and the outer edges of the front and rear straight walls at the thick slag bucket, and then base the elevation on both ends. Pop up the vertical center line to the bottom of the ash hopper, and set the size at the bottom of the ash hopper. After popping the vertical auxiliary line, use the produced triangle template (made according to the slope of the inclined wall in the drawing), and draw the side line of the inclined wall on both ends of the foundation stand. Surface. Use the same material of refractory concrete to make the triangular setback at the bottom of the inclined wall (as shown in Figure 1) and level the straight wall. The triangular setback at the junction of the vertical, horizontal and inclined walls shall also be poured with refractory concrete of the same material. Proceed to masonry sloping walls.

(2) Lokacin gina guga na toka, fara gina a kwance sannan kuma a tsaye; Idan aka yi katangar karkatacciya da katangar madaidaiciya, sai a fara gina madaidaicin bango sannan kuma katanga mai karkata.

(3) When there is foundation support on the back of the inclined wall, the mortar on the contact surface between the bricks and the foundation should be full; Once cinder, cinder must be compacted.

5. Masonry na madaidaiciyar bango:

(1) The straight walls around the boiler are composed of refractory bricks, thermal insulation bricks (or thermal insulation layer), and red bricks. The order of masonry construction is to build refractory bricks first, then thermal insulation bricks (or paste insulation boards or felt), and finally red bricks. For example, when the hot joint between the refractory brick and the red brick is filled, the filler should be filled every 3 to 4 layers of the red brick, and the filling should be dense.

(2) Lokacin gina katanga madaidaiciya, dole ne a sanya shi a kusurwar bangon tanderun. Dole ne a yi amfani da sassan biyu na sassan madaidaiciya tare da 2 ~ 3 yadudduka na kawunansu, kuma dole ne a riƙe layin kwance. Gina mahaɗin turmi, barin wuraren faɗaɗa a wuri, rataya igiyoyin faɗaɗawa na asbestos a tsaye, sannan a liƙa fakitin asbestos akan facade na ƙarfe kafin a ci gaba da ginin ginin.

(3) Hanyar masonry na madaidaiciyar bangon bango shine: 1/2 bango mai kauri mai kauri yana ɗaukar ɗakunan katako da 1/2 tsayin bulo; Bulo 1 kuma sama da bango mai kauri yana ɗaukar saman ɗaya da madaidaiciya ɗaya ko tsarin masonry kunshin. Ƙarƙashin saman ko ƙasa na bulo na bulo 1 da bulo mai kauri guda 1 za su kasance na sama ko na gefe.

(4) Lokacin da ɓangarorin biyu na bangon tanderun ke aiki (sai dai bangon da ke da kauri na bulo 1 ko ƙasa da haka), dole ne a shimfiɗa bangarorin biyu a lokaci guda.

(5) Ba za a gyara madaidaicin bangon da aka sanyaya ruwa da gefen bututu da madaidaicin goyan bayan bututun da ke wucewa ta cikin masonry ba, kuma bulo mai siffa ta musamman a ƙugiya mai sanyaya na bangon da aka sanyaya ruwa ba za ta matse ba. farantin kunne na bango mai sanyaya ruwa.

(6) When the refractory bricks and red bricks are assembled, when the refractory bricks are built with 6 to 8 layers of brick height, every 1 to 1.5m along the horizontal direction, 115mm long stretched bricks must be extended to the outer wall of the red bricks. Tensioned bricks should be disconnected on the same layer, and the upper and lower layers should be staggered.

(7) Lokacin gina bangon waje na tubalin ja, dole ne a samar da ramukan huɗa, kuma rarraba wurin da aka keɓe ya kamata ya kasance daidai. Ana iya ajiye mutum a kusan 2m2 kuma a binne shi tare da bututun ƙarfe na baƙin ƙarfe DN15 ~ 20 (a cikin yanayin da ba za a iya kaucewa ba, yi amfani da hanyar rami na 60 × 120mm da aka tanada). Ana fara saita tukunyar jirgi tare da grate lokacin da aka zubar; Za a fara saita tukunyar jirgi marasa grate a wani tsayin da ya kai kimanin mita 1, kuma dole ne a kafa mafi girman wurin kabu, kuma za a toshe tanderun da kayan da ke jure zafin jiki nan da nan bayan an gama tanda.

6. The masonry of furnace wall openings, inspection holes, etc. adopts the masonry method that the refractory bricks of the inner wall penetrate to the red bricks of the outer wall (see Figure 2). When the upper covering design of the opening (hole) is required, the masonry shall be built according to the design requirements, and when the design is not required, the masonry shall be built in the following manner:

(1) Nisa na rami (rami) a bango bai kai ko daidai da 450mm ba. Idan tazarar ba ta da girma, ana iya amfani da ƙaƙƙarfan hanyar dandamali don maye gurbin ƙaramin baka tare da lebur tubali. Ana nuna hanyar masonry a cikin Hoto 3. Kowane Layer zai fito ≤6mm daga bangarorin biyu zuwa cikin budewa har sai an rufe budewa. Tsawon tsayin da aka yi na kowane Layer da wannan Layer zai kasance iri ɗaya.

(2) Nisa na buɗewa (rami) a bangon ≤250mm ana iya rufe shi ta hanyar tubalin sarrafawa. Ana nuna hanyar masonry a hoto na 4.

(3) Nisa na rami a bango> faɗin 450mm za a rufe shi da masonry mai juyawa.

7. Masonry of arch and vault:

(1) Radius gyare-gyaren taya da girman samarwa da ake buƙata don baka da masonry dole ne su dace da buƙatun ƙira. Matsakaicin ƙirar taya yana ƙasa da ainihin tazara ta 20 ~ 30mm, saman yana da lebur kuma yana da santsi, kuma yana da kayan ɗaukar nauyi da kayan gini ba tare da nakasu ba.

(2) Kafin ginin ginin, dole ne a kammala ginin ginin da ke bayan bulogin ƙafar ƙafa, kuma za a iya gina ginin kawai bayan an wuce binciken. Bayan tubalin kafa na baka, ba a yarda a gina tubalin da ke hana zafi ba ko tubalin algae na ƙasa.

(3) Kafin a gina saman baka, katakon yatsan yatsan baka da ginshiƙin firam ɗin dole ne su kasance kusa da juna. Kafin sanya baka na firam ɗin daidaitacce, firam ɗin da sandunan ƙulla dole ne a daidaita su kuma a daidaita su, sannan a wuce dubawa.

(4) Kafin katangar baka da masonry, da farko shigar da gyare-gyaren taya, duba tsayi da matsayi, gyara shi da kyau, sa’an nan kuma aiwatar da aikin ginin. Manufar pre-masonry shine yafi daidaita haɗin ginin turmi da kuma haɗa tubalin baka. Samfurin don saduwa da buƙatun ingancin masonry na baka da ɗimbin abubuwan haɗin gwiwa. Bayan tsarin taron tubali na baka ya cika abubuwan da ake bukata, ana ƙididdige fuskokin tubalin bisa ga tsari na masonry sannan a cire su, kamar yadda aka nuna a hoto na 5. Dole ne a gina ginin mason daga ƙafar baka zuwa tsakiya a lokaci guda. An haramta sosai a kifar da ginin ginin.

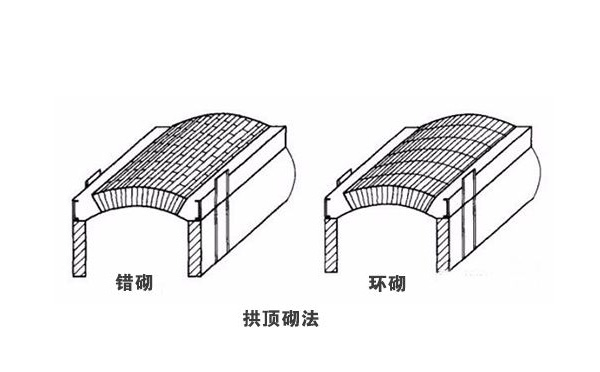

(5) Sai dai in ba wasu ƙa’idodi na musamman ba, za a sanya ma’ajiyar tudu da rumbun ajiya a cikin mahaɗar da ba a taɓa gani ba, kuma ana iya shimfiɗa baka da tafkuna daban-daban a cikin zobe. A cikin yanayin masonry na haɗin gwiwa, lokacin da tsayin haɗin gwiwa ya fi tsayi fiye da mita 1, dole ne a zana ginin tare da layi.

(6) Dole ne a shigar da tubalin kulle a cikin masonry na baka da saman sama. Zurfin tubalin kulle da aka gina a ciki shine 2/3 ~ 3/4 na kauri na baka da saman sama. Kamar yadda aka nuna a hoto na 6, zurfin kulle na baka ɗaya dole ne ya zama iri ɗaya. , Lokacin kullewa, yakamata ya kasance daga makulli mai matsewa zuwa madaidaicin. A cikin bangon, ɗakunan da ke kusa da su da kuma tubalin kulle na rufin rufi dole ne a fitar da su a lokaci guda don hana nakasar da ke kusa.

(7) The lock bricks are distributed evenly and symmetrically. Drive into one lock brick for span <3m, and drive 3 lock bricks for span> 3m. You can use a hammer to drive in when it is locked, but it must be padded with a wooden board.

(8) Ba a yarda a yi amfani da tubalin da ke da kauri fiye da 1/3 ko yanke dogon gefe don yin babban saman ya zama siffa mai tsutsa a matsayin tubalin kulle.

(9) Domin tubalin da aka sarrafa wanda aka daidaita a saman saman baka da rumbun, ana iya daidaita wurin da zafin jiki mai zafi ko saman bangon waje ta hanyar sarrafa bulo, kuma ana iya daidaita wurin da ƙananan zafin jiki ta hanyar iri ɗaya. abu na refractory kankare.

8. Upside-down masonry:

(1) Ana yin alluna masu siffar baka guda biyu ciki da waje yayin da ake juye juye-juye. An yi farantin baka na ciki bisa ga radius na juyawa; farantin baka na waje an yi shi tare da radius na ciki tare da kauri na bulo mai juyawa.

(2) Lokacin gina jujjuyawar juye-juye, layin tsakiya na ƙasa na juyawa yana dogara ne akan shinge mai siffar baka, kuma an gina ƙananan ɓangaren. Gabaɗaya, tsayin bulo na iya saduwa da tubalin jujjuya 5 ~ 7, sannan zaku iya fara ginin juye. Juyawa, sa’an nan kuma a misalta gina juye daga tsakiyar kasan juye zuwa ɓangarorin biyu. Kar a buga da karfi lokacin fara gini don gujewa juyawa ko sassautawa. Bayan an gina tubalin 5 ~ 7 a cikin ƙananan ɓangaren juzu’in da aka juya, an kafa katako mai siffar baka na ciki a saman bulo mai jujjuya, kuma an shimfiɗa tubalin a hankali a bangarorin biyu a cikin tsari na jujjuya tubalin sannan sannan sarrafa tubalin. Ana nuna jerin masonry a hoto na 7.

(3) Lokacin da aka juya zuwa 1/2 da’irar, na sama 1/2 yana ɗaukar baka da masonry. Lokacin kulle tubalin, juya tubalin a kusa da 1/2 na tsayi na sama sannan kuma ku kulle tubalin bayan an gama ginin, kamar yadda aka nuna a hoto 8.

9. Masonry na tubalin rataye da rushe bangon harshen wuta:

(1) Hanging bricks and removing flame walls follow the principle of building from low to high, from the middle to both sides.

(2). Lokacin da ake buƙatar sarrafa bulo don gina tubalin rataye da bangon masu cire harshen wuta, share ramukan rataye na tubalin da aka rataye ba zai zama fiye da 5mm ba, kuma kauri daga bangon cire harshen wuta ba zai zama ƙasa da 90 ba. %. Kada a sami fasa a cikin manyan sassan da ke da ƙarfi na tubalin rataye.

(3) Don bulogi masu siffa na musamman tare da gyaran ramukan ƙwanƙwasa, na farko busassun jeri ta Layer don shimfiɗawa gwaji, kuma bayan sanya alamar ramukan ƙugiya a kan bututun, za a iya yin welded ƙusoshin. Kada a danne ƙwaya da ƙarfi sosai yayin ginin ginin don guje wa lalata tubalin da ke karkatar da su, kuma a cika ramukan kulle da siminti.

10. The expansion joints of the furnace wall are left:

(1) Wuri da nau’i na haɓakar haɓakawa a kan bangon tanderun sun dace da bukatun ƙira. Ba a yarda da nisa ya zama ƙarami fiye da buƙatun ƙira, kuma abubuwa masu wuya irin su tubalin da aka karya ba a yarda su fada cikin haɗin gwiwa. Ana tattara marufi a cikin haɗin gwiwa ta haɓaka sosai bisa ga buƙatun ƙira. Lokacin da ake amfani da igiyar asbestos, na farko zuwa saman harshen wuta dole ne a jika shi a cikin laka mai jujjuyawa.

(2) Bututun bango na ruwa, masu saukarwa, masu kai, bututun najasa, ganguna, ramukan auna zafin jiki (tubes) da katako, da dai sauransu, ta bangon, barin haɗin gwiwa a bangon lamba da haɗin kai tsaye da kwance na tanderun bulo mai jujjuyawa. bango. Zai fi kyau a yi iska da igiya asbestos.

(3) Hanyar barin shingen fadada bangon tanderun:

①. An nuna hanyar da ake riƙe da haɗin gwiwar fadadawa a sasanninta a cikin Hoto 9 (a): hanyar barin haɗin 1/2 tubali da 1 tubali; Hoto 9 (b): Hanyar barin mahaɗin tubali 1 da bulo 1.

②. Ana nuna hanyar saita haɗin haɗin gwiwa a mahaɗin ƙarshen biyu na bangon rushewa da bangon tander a cikin hoto na 10.

③. Hanyar shimfida haɗin gwiwa ta tsaye a tsakiyar bangon tanderun ana nuna shi a hoto na 11.

④ Ana nuna hanyar saita faɗaɗa haɗin gwiwa a mahaɗar rufin tanderun da ƙarshen bangon rataye da bangon tander a hoto na 12.

⑤ A kwance shimfidar haɗin ginin bangon tanderan ana yin su ne da tubali na musamman. Idan babu bulo mai siffa ta musamman, ana amfani da hanyar da aka nuna a hoto na 13 don masonry. Lokacin da aka shimfiɗa haɗin haɗin gwiwa a kwance, igiyar asbestos ya kamata a matsa; Tsawon bulogin da ke sama da haɗin gwiwar faɗaɗa a kwance bai kamata ya wuce mita 1 ba, kuma bulo ɗin da ke jujjuyawar da jajayen bulo za su tashi a madadin haka don hana igiyar asbestos matsawa da haifar da karkatar da bangon tanderu.

(4) Ƙwararren haɓaka na tsaye yana rataye layi don masonry, haƙoran da ba daidai ba bai wuce 3mm ba, kuma igiyar asbestos a cikin haɗin gwiwa ya fi girma fiye da sauran nisa na fadada haɗin gwiwa ta 3 ~ 5mm, kuma an danna shi. a lokaci guda a lokacin masonry.

11. Refractory bricks and thermal insulation bricks are not allowed to wet the bricks, and the red bricks must be watered until the outside is dry and the inside is saturated before the red bricks are built.

12. It is not allowed to process bricks or walk on the masonry, and it is not allowed to face the processing surface of the bricks to the flame surface.

13. The surfaces of refractory bricks and red bricks must be jointed. Where the convection tube bundles are concentrated and where the boiler accessories are blocked, the ash ears must be scraped off along with the masonry.

Gine-gine galibi hanyar haɗin gwiwa ce da kamfanoni sukan yi watsi da su. Kullum suna tunanin cewa samfurori masu kyau da kyawawan kayayyaki na iya tabbatar da rayuwar sabis na kiln. A cikin ma’auni na ƙasa, akwai ƙaƙƙarfan ƙa’idodi game da ginin rotary kiln, kamar haka: