- 12

- Feb

Indlela yokwakha izitini ze-refractory ze-boiler?

Indlela yokwakha izitini refractory of kubhayela?

1. Izinyathelo zokwakha zenziwa ngokuhambisana nesimiso kusukela phansi kuya phezulu futhi kusukela ngaphakathi kuya ngaphandle. Ingxenye engezansi yesigubhu esingaphezulu kanye nepuleti lelangabi lesikhawu le-convection tube bundle lithelwa ukusuka phezulu kuye phansi.

2. Udonga lwesithando somlilo lunezidingo eziphezulu zokuqina komoya, nokugcwala kwamalunga omlotha: izitini ezibomvu azikho ngaphansi kuka-85%; izitini eziphikisayo azikho ngaphansi kwama-90%. Indlela yokukhama isetshenziselwa ukwakha izitini ezibomvu, futhi indlela yokukhuhla isetshenziselwa ukwakhiwa kwezitini eziphikisayo.

3. Ukwakhiwa kwesithando somlilo phansi:

(1) Before the furnace bottom is laid, the foundation should be leveled, and the surrounding straight walls in contact with the furnace bottom should be built first, and the height should be approximately higher than the surface of the furnace bottom. Then mark the horizontal line of the furnace bottom (in the case of multi-layer masonry, together with the number of layers) on the straight wall before the furnace bottom can be built.

(2) Lapho indawo engaphansi yesithando somlilo yakhiwe izingqimba eziningi zezitini, ukwakhiwa kwamatshe kufanele kwenziwe ungqimba ngongqimba, izendlalelo ezingaphezulu nezingaphansi kanye nongqimba olufanayo lwezitini luyanyakaza, futhi izinhlangothi ezinde zezitini eziningi zongqimba olungaphezulu ziyanyakaza. perpendicular isiqondiso sokugeleza kwe-slag noma igesi.

(3) Ezindaweni ezishisa kakhulu nezingaphansi kwesithando somlilo okuvamise ukudinga ukulungiswa, igebe lokunweba kufanele lishiywe lapho kuxhunywana khona phakathi kwesithando somlilo nodonga oluqondile, futhi intambo ye-asbestos noma ibhodi le-asbestos lephedi kufanele lifakwe esikhaleni.

4. Masonry of ash bucket (including inclined wall):

(1) Ngaphambi kokwakha ibhakede lomlotha, qala uthole umugqa ophakathi nendawo ovundlile ngokwemidwebo, bese usebenzisa umugqa ophakathi nendawo ovundlile ukuze uthole umugqa ophakathi nendawo webhakede lomlotha ngalinye kanye nemiphetho yangaphandle yezindonga zangaphambili nezingemuva eziqondile endaweni ewugqinsi ye-slag. ibhakede, bese usekela ukuphakama kuzo zombili iziphetho. Phakamisa umugqa omaphakathi oqondile uye phansi kwe-ash hopper, bese usetha usayizi phansi kwe-ash hopper. Ngemva kokuphuma komugqa wokusiza ome mpo, sebenzisa ithempulethi engunxantathu ekhiqiziwe (eyenziwe ngokuhambisana nomthambeka wodonga oluthambekile emdwebeni), bese udweba umugqa oseceleni wodonga oluthambekele kuzo zombili iziphetho zesisekelo sokuma. Ubuso. Sebenzisa into efanayo yekhonkrithi ephikisayo ukuze wenze ukubuyisela emuva kukanxantathu ngaphansi kodonga oluthambekele (njengoba kuboniswe kuMfanekiso 1) futhi ulinganise udonga oluqondile. Ukuhlehla kukanxantathu lapho kuhlangana khona izindonga eziqondile, ezivundlile nezigobile kuzophinde kuthelwe ngokhonkolo ophikisayo wento efanayo. Qhubekela ezindongeni ezitshekile zamatshe.

(2) Lapho wakha ibhakede lomlotha, qala elakhe elivundlile bese emva kwalokho elakhe mpo; lapho udonga oluthambekile nodonga oluqondile lwakhiwe, yakha udonga oluqondile kuqala bese emva kwalokho udonga oluthambekile.

(3) Uma kunesisekelo esisekelweni ngemuva kodonga oluthambekile, udaka endaweni ethintwayo phakathi kwezitini nesisekelo kufanele lugcwale; Uma i-cinder, i-cinder kufanele ihlanganiswe.

5. Ukwakhiwa kwezindonga eziqondile:

(1) The straight walls around the boiler are composed of refractory bricks, thermal insulation bricks (or thermal insulation layer), and red bricks. The order of masonry construction is to build refractory bricks first, then thermal insulation bricks (or paste insulation boards or felt), and finally red bricks. For example, when the hot joint between the refractory brick and the red brick is filled, the filler should be filled every 3 to 4 layers of the red brick, and the filling should be dense.

(2) When building a straight wall, it must be placed at the corner of the furnace wall. The two ends of the straight section must be yarded with 2~3 layers of heads, and the horizontal line must be held. Build the mortar joints, leave the expansion joints in place, hang the vertical expansion joints asbestos ropes, and paste the asbestos panels on the steel frame facade before proceeding to masonry.

(3) Indlela yokwakhiwa kwamatshe odongeni oluqondile yile: 1/2 udonga oluwugqinsi lwezitini luthatha amalunga anyakazayo kanye nobude bezitini obuyi-1/2; Isitini esingu-1 nangaphezulu kodonga oluwugqinsi sisebenzisa ingaphezulu elilodwa kanye nephakheji elilodwa eliqondile noma indlela yokukhiya yamatshe. Ungqimba olungaphezulu noma olungezansi lwezitini zesitini esi-1 kanye nongqimba oluwugqinsi lwesitini esisodwa luzoba phezulu noma ohlangothini.

(4) Uma izinhlangothi zombili zodonga lwesithando somlilo ziyizindawo zokusebenza (ngaphandle kwezindonga ezinogqinsi lwesitini esi-1 noma ngaphansi), izinhlangothi zombili kufanele zibekwe ngesikhathi esisodwa.

(5) The water-cooled wall header and the pipe side and the sliding support of the pipe side passing through the masonry shall not be fixed, and the special-shaped brick at the pull hook of the water-cooled wall shall not jam the ear plate of the water-cooled wall.

(6) When the refractory bricks and red bricks are assembled, when the refractory bricks are built with 6 to 8 layers of brick height, every 1 to 1.5m along the horizontal direction, 115mm long stretched bricks must be extended to the outer wall of the red bricks. Tensioned bricks should be disconnected on the same layer, and the upper and lower layers should be staggered.

(7) Lapho kwakhiwa udonga olungaphandle lwezitini ezibomvu, kufanele kube nezimbobo zokuphuma, futhi ukwaba indawo egodliwe kufanele kulingane. Umuntu angagcinwa cishe ku-2m2 futhi angcwatshwe ngamapayipi ensimbi amnyama e-DN15~20 (uma kunezimo ezingagwemeki, sebenzisa indlela yembobo egodliwe engu-60 × 120mm). Ama-boilers ane-grate aqala ukumiswa lapho i-grate ishaywa; ama-boilers ngaphandle kwe-grate aqala ukumiswa endaweni ephakeme engaba ngu-1m, futhi indawo ephakeme kakhulu ye-insulation seam kufanele futhi imiswe, futhi isithando somlilo sizovinjelwa ngezinto ezivimbela ukushisa ngokushesha ngemva kokuba ihhavini isiqediwe.

6. Ukwakhiwa kwezindonga zesithando somlilo, izimbobo zokuhlola, njll zamukela indlela yokumisa ukuthi izitini eziphikisayo zodonga lwangaphakathi zingene ezitini ezibomvu zodonga lwangaphandle (bheka Umfanekiso 2). Lapho umklamo ongaphezulu wokumboza wokuvula (umgodi) udingeka, i-masonry izokwakhiwa ngokuvumelana nezidingo zokuklama, futhi lapho umklamo ungadingeki, ukwakhiwa kwamatshe kuzokwakhiwa ngale ndlela elandelayo:

(1) Ububanzi bembobo (imbobo) odongeni bungaphansi noma bulingana no-450mm. Uma i-span ingenkulu, indlela yesikhulumi esiqinile ingasetshenziswa esikhundleni se-arch encane ngesendlalelo sezitini esiyisicaba. Indlela ye-masonry iboniswa kuMfanekiso 3. Ungqimba ngalunye luzophuma ≤6mm kusuka ezinhlangothini zombili ukuya ekuvuleni kuze kube yilapho ukuvulwa kuvaliwe. Ubude obuphumile besendlalelo ngasinye kanye nongqimba olufanayo buzofana.

(2) Ububanzi bokuvula (umgodi) odongeni ≤250mm bungambozwa ngokucubungula izitini. Indlela ye-masonry iboniswe kuMfanekiso 4.

(3) Ububanzi bembobo odongeni> 450mm ububanzi buyombozwa ngamatshe ajikelezayo.

7. Ukwakhiwa kwe-arch ne-vault:

(1) Irediyasi yesikhunta samasondo kanye nosayizi wokukhiqiza we-radian odingekayo kuma-arch kanye ne-vault masonry kumele ihlangabezane nezidingo zokuklama. Ubude besikhunta sesondo singaphansi kwe-span yangempela ngo-20 ~ 30mm, indawo engaphezulu iphansi futhi ibushelelezi, futhi inezinto ezithwala imithwalo kanye nemithwalo yokwakha ngaphandle kwe-deformation Amandla.

(2) Ngaphambi kwe-arch masonry, i-masonry ngemuva kwezitini ze-arch-foot kufanele igcwaliswe, futhi i-masonry ingakhiwa kuphela ngemva kokuphumelela ukuhlolwa. Ngemuva kwezitini ze-arch-foot, akuvunyelwe ukwakha izitini ze-refractory ezivimbela ukushisa noma izitini zomhlaba ze-brick algae.

(3) Ngaphambi kokuba i-arch top yakhiwe, i-arch toe beam kanye nekholomu yefreyimu kufanele kusondelene. Ngaphambi kokubeka i-arch yefreyimu eguquguqukayo, ifreyimu kanye nezinduku zokubopha kufanele zilungiswe futhi zilungiswe, futhi zidlule ukuhlolwa.

(4) Ngaphambi kwe-arch kanye ne-vault masonry, qala ufake isikhunta sethayi, uhlole ukuphakama nendawo, uyilungise ngokuqinile, bese wenza i-pre-masonry. Inhloso ye-pre-masonry ngokuyinhloko ukulungisa amalunga odaka futhi ahlanganise izitini ze-arch. Imodeli yokuhlangabezana nezidingo zekhwalithi ye-arch masonry namajoyinti anyakazayo. Ngemuva kokuthi ukuhlelwa kokuhlanganiswa kwezitini ze-arch kuhlangabezana nezidingo, ubuso bezitini bubalwa ngokuvumelana nokuhlelwa kwe-masonry bese bususwa, njengoba kuboniswe ku-Figure 5. I-masonry kumele yakhiwe ngokulinganayo kusukela ku-arch foot kuya esikhungweni ngesikhathi esifanayo. Kwenqatshelwe ngokuphelele ukubhekela phansi i-masonry.

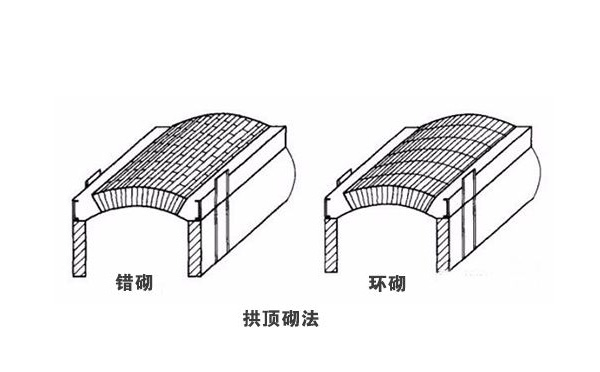

(5) Unless there are special regulations, the arches and vaults shall be laid in staggered joints, and arches and vaults with different spans can be laid in rings. In the case of staggered joint masonry, when the length of the longitudinal joint is longer than 1 meter, the masonry must be drawn with a line.

(6) Izitini zokukhiya kufanele zifakwe endaweni eyi-arch kanye ne-vault top. Ukujula kwezitini zokukhiya ezakhelwe ngaphakathi kungu-2/3~3/4 wogqinsi lwe-arch ne-vault top. Njengoba kuboniswe kuMfanekiso 6, ukujula kwengidi ye-arch efanayo kufanele kufane. , Uma uvala phakathi, kufanele isuke kusikhiya esiqinile siye kwesixegayo. Odongeni, ama-arches amaningana aseduze kanye nezitini zokukhiya ophahleni lwe-arch kumele ziqhutshwe ngesikhathi esifanayo ukuvimbela ukuguqulwa kwama-arches aseduze.

(7) The lock bricks are distributed evenly and symmetrically. Drive into one lock brick for span <3m, and drive 3 lock bricks for span> 3m. You can use a hammer to drive in when it is locked, but it must be padded with a wooden board.

(8) Akuvunyelwe ukusebenzisa izitini ezinogqinsi olungaphezu kwe-1/3 noma ukusika uhlangothi olude ukwenza indawo enkulu ibe yi-wedge njengesitini sokukhiya.

(9) Ezitini ezicutshungulwayo ezilinganiswe engxenyeni engenhla ye-arch kanye ne-vault, indawo yokushisa ephezulu noma indawo engaphezulu yodonga lwangaphandle ingalinganiswa ngokucutshungulwa kwezitini, futhi indawo yokushisa ephansi ingalinganiswa ngokufanayo. impahla yekhonkrithi ephikisayo.

8. Upside-down masonry:

(1) Two arc-shaped boards inside and outside are made when turning upside-down masonry. The inner arc plate is made according to the radius of the rotation; the outer arc plate is made with the inner radius plus the thickness of the rotating brick.

(2) Uma wakha ukuzungeza okubheke phansi, umugqa omaphakathi ophansi wokuzungeza usekelwe ku-slab emise okwe-arc, futhi ingxenye engezansi yakhiwe. Ngokuvamile, ubude besitini bungahlangana nezitini ezijikelezayo ezingu-5 ~ 7, bese ungaqala ukwakha ubheke phansi. Zungezisa, bese wakha ngokulinganayo ubheke phansi ukusuka phakathi nendawo phansi kokubheke phansi kuya ezinhlangothini zombili. Ungashayi kakhulu uma uqala ukwakha ukuze ugweme ukugudluka noma ukuxega. Ngemuva kokuthi izitini ezi-5 ~ 7 zakhiwe engxenyeni engezansi yesikulufu esiguquliwe, ibhodi elingaphakathi eline-arc lilungiswa phezu kwesitini esijikelezayo, futhi izitini zibekwe ngokulinganayo ezinhlangothini zombili ngokulandelana kokuzungeza izitini bese emva kwalokho. ukucubungula izitini. Ukulandelana kwamatshe kuboniswe kuMfanekiso 7.

(3) Lapho ujikela kumbuthano ongu-1/2, i-1/2 engaphezulu ithatha i-arch kanye ne-vault masonry. Lapho ukhiya izitini, phendula izitini zizungeze i-1/2 yobude be-vector engenhla bese ukhiya izitini ngemva kokuqedwa kokwakhiwa kwamatshe, njengoba kuboniswe kuMfanekiso 8.

9. Ukwakhiwa kwezitini ezilengayo nokubhidlizwa kwezindonga zomlilo:

(1) Hanging bricks and removing flame walls follow the principle of building from low to high, from the middle to both sides.

(2). Lapho izitini zidinga ukucutshungulwa ukuze kwakhiwe izitini ezilengayo kanye nezindonga ezikhipha amalangabi, ukucaciswa kwemigodi yokulenga yezitini ezilengayo akufanele kube ngaphezu kuka-5mm, futhi ubukhulu bezindonga ezikhipha ilangabi akufanele kube ngaphansi kwama-90. %. Akumelwe kube khona imifantu ezingxenyeni eziyinhloko ezithwala amandla ezitini ezilengayo.

(3) Izitini ezimise okukhethekile ezinezimbobo zokulungisa izimbobo, umugqa wokuqala owomile ngongqimba wokubekwa kwesilingo, futhi ngemuva kokumaka indawo yezimbobo zebholithi epayipini, ama-bolts okulungisa angafakwa. Amantongomane akufanele aqiniswe ngokuqinile ngesikhathi sokwakhiwa kwamatshe ukuze agweme ukulimaza izitini eziphikisayo, futhi izimbobo ze-bolt kufanele zigcwaliswe ukhonkolo ophikisayo.

10. Ukunwetshwa kodonga lwesithando somlilo kusele:

(1) The location and form of the expansion joints on the furnace wall are in accordance with the design requirements. The width is not allowed to be smaller than the design requirements, and hard objects such as broken bricks are not allowed to fall into the joints. The packing in the expansion joint is tightly packed according to the design requirements. When asbestos rope is used, the first one to the flame surface must be soaked in refractory mud.

(2) Amapayipi amanzi odongeni, ezehlisayo, izihloko, amapayipi endle, izigubhu, izimbobo zokulinganisa izinga lokushisa (amashubhu) nemishayo, njll., ngodonga, shiya amalunga okunweba odongeni lokuxhumana kanye nokuxhumana okuqondile nokuvundlile kwesithando somlilo sezitini udonga. Kungcono ukuvunguza ngentambo ye-asbestos.

(3) Indlela yokushiya ukunwetshwa kodonga lwesithando somlilo:

①. Indlela yokugcina amalunga okunweba emakhoneni ikhonjiswe kuMfanekiso 9(a): indlela yokushiya ukuhlangana kwe-1/2 yezitini kanye nesitini esi-1; Umfanekiso 9(b): indlela yokushiya ukuhlangana kwesitini esi-1 nesitini esi-1.

②. Indlela yokubeka amalunga okunweba lapho kuhlangana khona imikhawulo emibili yodonga lokubhidliza kanye nodonga lwesithando somlilo kuboniswe kuMfanekiso 10.

③. The vertical expansion joint staying method in the middle of the furnace wall is shown in Figure 11.

④. Indlela yokubeka amalunga okunweba lapho kuhlangana khona uphahla lwesithando somlilo kanye neziphetho ezimbili ze-arch elengayo kanye nodonga lwesithando somlilo kuboniswe kuMfanekiso 12.

⑤ Amalunga odonga lwesithando somlilo ngokuvamile enziwa ngezitini ezimise okukhethekile. Uma zingekho izitini ezimise okukhethekile, indlela eboniswe kuMfanekiso 13 isetshenziselwa ukwakha. Uma ubeka i-joint yokwandisa evundlile, intambo ye-asbestos kufanele icindezelwe; ukuphakama kwezitini eziphikisayo ngaphezu kwejoyinti yokwandisa evundlile akufanele kudlule i-1m, futhi izitini eziphikisayo nezitini ezibomvu zizophakama ngokushintshana ukuze kuvinjelwe intambo ye-asbestos ukuthi ingacindezelwa futhi yenze udonga lwesithando somlilo lutsheke.

(4) Ijoyinti lokunweba elime mpo lilenga ulayini wokwakha, izinyo elingalungile alikho ngaphezu kuka-3mm, futhi intambo ye-asbestos ejoyintini lokunweba inkulu kancane kunobubanzi obusele bejoyinti lokunweba ngo-3~5mm, futhi iyacindezelwa. ngesikhathi esifanayo ngesikhathi sokwakha.

11. Izitini ze-refractory kanye nezitini zokushisa ezishisayo azivunyelwe ukumanzisa izitini, futhi izitini ezibomvu kufanele ziniselwe kuze kube yilapho ngaphandle komile futhi ngaphakathi kugcwele ngaphambi kokuba kwakhiwe izitini ezibomvu.

12. Akuvunyelwe ukucubungula izitini noma ukuhamba phezu kwamatshe, futhi akuvunyelwe ukubhekana nokucubungula ubuso bezitini endaweni yomlilo.

13. Izitini eziphikisayo nezibomvu kufanele zihlanganiswe. Lapho izinyanda zamashubhu e-convection zigxilile nalapho izinto ezisetshenziswa kubhayela zivimbekile, izindlebe zomlotha kufanele zisuswe kanye ne-masonry.

Ukwakhiwa kuvame isixhumanisi izinkampani ezivame ukungazinaki. Bahlale becabanga ukuthi imikhiqizo emihle nemiklamo emihle ingaqinisekisa impilo yesevisi yeziko. Ngokwezinga likazwelonke, kunemithethonqubo eqinile ekwakhiweni kweziko elijikelezayo, kanje: