- 12

- Feb

How to build the refractory bricks of the boiler?

How to build the refractory bricks of หม้อไอน้ำ?

1. The construction steps are carried out in accordance with the principle of from bottom to top and from inside to outside. The lower part of the upper drum and the convection tube bundle interval flame plate are poured from top to bottom.

2. The furnace wall has high air-tightness requirements, and the fullness of ash joints: red bricks are not less than 85%; refractory bricks are not less than 90%. The squeezing method is used for red brick masonry, and the scraping method is used for refractory brick masonry.

3. Masonry of furnace bottom:

(1) Before the furnace bottom is laid, the foundation should be leveled, and the surrounding straight walls in contact with the furnace bottom should be built first, and the height should be approximately higher than the surface of the furnace bottom. Then mark the horizontal line of the furnace bottom (in the case of multi-layer masonry, together with the number of layers) on the straight wall before the furnace bottom can be built.

(2) When the furnace bottom is composed of multiple layers of bricks, the masonry should be carried out layer by layer, with the upper and lower layers and the same layer of bricks staggered, and the long sides of the most surface layer bricks are perpendicular to the flow direction of slag or gas.

(3) In high-temperature areas and furnace bottoms that often need to be overhauled, an expansion gap should be left at the contact between the furnace bottom and the straight wall, and asbestos rope or pad asbestos board should be embedded in the gap.

4. Masonry of ash bucket (including inclined wall):

(1) Before building the ash bucket, first find out the horizontal centerline according to the drawings, and use the horizontal center line to find the longitudinal centerline of each ash bucket and the outer edges of the front and rear straight walls at the thick slag bucket, and then base the elevation on both ends. Pop up the vertical center line to the bottom of the ash hopper, and set the size at the bottom of the ash hopper. After popping the vertical auxiliary line, use the produced triangle template (made according to the slope of the inclined wall in the drawing), and draw the side line of the inclined wall on both ends of the foundation stand. Surface. Use the same material of refractory concrete to make the triangular setback at the bottom of the inclined wall (as shown in Figure 1) and level the straight wall. The triangular setback at the junction of the vertical, horizontal and inclined walls shall also be poured with refractory concrete of the same material. Proceed to masonry sloping walls.

(2) When building the ash bucket, first build the horizontal and then the vertical; when the inclined wall and the straight wall are formed, build the straight wall first and then the inclined wall.

(3) When there is foundation support on the back of the inclined wall, the mortar on the contact surface between the bricks and the foundation should be full; Once cinder, cinder must be compacted.

5. Masonry of straight walls:

(1) The straight walls around the boiler are composed of refractory bricks, thermal insulation bricks (or thermal insulation layer), and red bricks. The order of masonry construction is to build refractory bricks first, then thermal insulation bricks (or paste insulation boards or felt), and finally red bricks. For example, when the hot joint between the refractory brick and the red brick is filled, the filler should be filled every 3 to 4 layers of the red brick, and the filling should be dense.

(2) When building a straight wall, it must be placed at the corner of the furnace wall. The two ends of the straight section must be yarded with 2~3 layers of heads, and the horizontal line must be held. Build the mortar joints, leave the expansion joints in place, hang the vertical expansion joints asbestos ropes, and paste the asbestos panels on the steel frame facade before proceeding to masonry.

(3) The masonry method of straight wall masonry is: 1/2 brick thick wall adopts staggered joints and 1/2 brick length masonry; 1 brick and above thick wall adopts one top and one straight or lock package masonry method . The top or bottom layer of bricks of 1 brick and 1 brick thick masonry shall be top or side masonry.

(4) When both sides of the furnace wall are working surfaces (except for walls with a thickness of 1 brick or less), both sides are to be laid at the same time.

(5) The water-cooled wall header and the pipe side and the sliding support of the pipe side passing through the masonry shall not be fixed, and the special-shaped brick at the pull hook of the water-cooled wall shall not jam the ear plate of the water-cooled wall.

(6) When the refractory bricks and red bricks are assembled, when the refractory bricks are built with 6 to 8 layers of brick height, every 1 to 1.5m along the horizontal direction, 115mm long stretched bricks must be extended to the outer wall of the red bricks. Tensioned bricks should be disconnected on the same layer, and the upper and lower layers should be staggered.

(7) When building the outer wall of red bricks, vent holes must be provided, and the distribution of the reserved space should be even. One can be reserved at about 2m2 and buried with DN15~20 black iron pipes (in the case of unavoidable circumstances, use reserved 60 ×120mm hole method). Boilers with grate start to be set up when the grate is flush; boilers without grate start to be set up at an elevation of about 1m, and the highest point of the insulation seam must also be set up, and the furnace shall be blocked with temperature-resistant materials immediately after the oven is completed.

6. The masonry of furnace wall openings, inspection holes, etc. adopts the masonry method that the refractory bricks of the inner wall penetrate to the red bricks of the outer wall (see Figure 2). When the upper covering design of the opening (hole) is required, the masonry shall be built according to the design requirements, and when the design is not required, the masonry shall be built in the following manner:

(1) The width of the hole (hole) in the wall is less than or equal to 450mm. If the span is not large, the solid platform method can be used to replace the small arch with a flat brick layer. The masonry method is shown in Figure 3. Each layer shall protrude ≤6mm from both sides into the opening until the opening is covered. The protruding length of each layer and the same layer shall be the same.

(2) The width of the opening (hole) in the wall ≤250mm can be covered by processing bricks. The masonry method is shown in Figure 4.

(3) The width of the hole in the wall> 450mm width shall be covered by arch-rotating masonry.

7. Masonry of arch and vault:

(1) The tire mold radius and radian production size required for arch and vault masonry must meet the design requirements. The span of the tire mold is less than the actual span by 20~30mm, the surface is flat and smooth, and it has load-bearing materials and construction loads without deformation Ability.

(2) Before arch masonry, the masonry behind the arch-foot bricks must be completed, and the masonry can only be built after passing the inspection. After the arch-foot bricks, it is not allowed to build heat-insulating refractory bricks or brick algae earth bricks.

(3) Before the arch top is built, the arch toe beam and the frame column must be close together. Before laying the arch of the adjustable frame, the frame and the tie rods must be adjusted and fixed, and passed the inspection.

(4) Before the arch and vault masonry, first install the tire mold, check the elevation and position, fix it firmly, and then carry out pre-masonry. The purpose of pre-masonry is mainly to adjust the mortar joints and assemble the arch bricks. Model to meet the requirements of arch masonry quality and staggered joints. After the arch brick assembly arrangement meets the requirements, the brick faces are numbered according to the order of masonry and then removed, as shown in Figure 5. The masonry must be symmetrically built from the arch foot to the center at the same time. It is strictly forbidden to upside down the masonry.

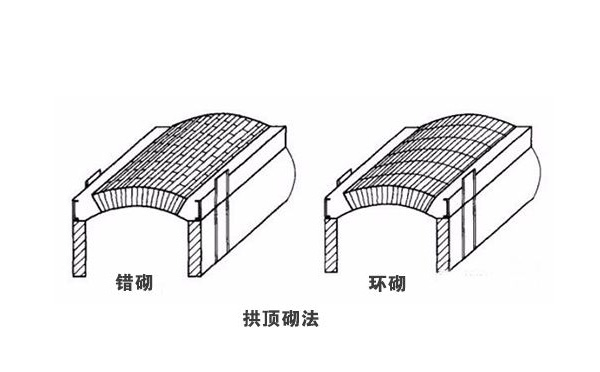

(5) Unless there are special regulations, the arches and vaults shall be laid in staggered joints, and arches and vaults with different spans can be laid in rings. In the case of staggered joint masonry, when the length of the longitudinal joint is longer than 1 meter, the masonry must be drawn with a line.

(6) Lock bricks must be installed in the masonry of the arch and vault top. The depth of the built-in lock bricks is 2/3~3/4 of the thickness of the arch and vault top. As shown in Figure 6, the lock depth of the same arch must be the same. , When locking in, it should be from the tighter lock to the looser. In the wall, several adjacent arches and the lock bricks of the arch roof must be driven in at the same time to prevent the deformation of the adjacent arches.

(7) The lock bricks are distributed evenly and symmetrically. Drive into one lock brick for span <3m, and drive 3 lock bricks for span> 3m. You can use a hammer to drive in when it is locked, but it must be padded with a wooden board.

(8) It is not allowed to use bricks that have a thickness of more than 1/3 or cut the long side to make the large surface into a wedge shape as a lock brick.

(9) For the processed bricks that are leveled on the upper part of the arch and the vault, the high temperature area or the surface of the external wall can be leveled by brick processing, and the low temperature area can be leveled by the same material of refractory concrete.

8. Upside-down masonry:

(1) Two arc-shaped boards inside and outside are made when turning upside-down masonry. The inner arc plate is made according to the radius of the rotation; the outer arc plate is made with the inner radius plus the thickness of the rotating brick.

(2) When building upside-down rotation, the bottom center line of the rotation is based on the arc-shaped slab, and the lower part is built. Generally, the length of the brick can meet 5~7 rotating bricks, then you can start to build upside down. Rotate, and then symmetrically build upside down from the center of the bottom of the upside down to both sides. Don’t hit too hard when starting to build to avoid shifting or loosening. After 5~7 bricks are built in the lower part of the inverted screw, the inner arc-shaped board is fixed on the surface of the rotating brick, and the bricks are symmetrically laid on both sides in the order of rotating the bricks and then processing the bricks. The masonry sequence is shown in Figure 7.

(3) When turning to 1/2 circle, the upper 1/2 adopts arch and vault masonry. When locking the bricks, turn the bricks around 1/2 of the upper vector height and then lock the bricks after the masonry is finished, as shown in Figure 8.

9. Masonry of hanging bricks and demolition of flame walls:

(1) Hanging bricks and removing flame walls follow the principle of building from low to high, from the middle to both sides.

(2). When bricks need to be processed for the construction of hanging bricks and flame-removing walls, the clearance of the hanging holes of the hanging bricks shall not be greater than 5mm, and the thickness of the flame-removing walls shall not be less than 90%. There shall be no cracks in the main force-bearing parts of the hanging bricks.

(3) For special-shaped bricks with fixing bolt holes, first dry row by layer for trial laying, and after marking the position of the bolt holes on the pipe, the fixing bolts can be welded. The nuts should not be tightened too tightly during masonry to avoid damaging the refractory bricks, and the bolt holes should be filled with refractory concrete.

10. The expansion joints of the furnace wall are left:

(1) The location and form of the expansion joints on the furnace wall are in accordance with the design requirements. The width is not allowed to be smaller than the design requirements, and hard objects such as broken bricks are not allowed to fall into the joints. The packing in the expansion joint is tightly packed according to the design requirements. When asbestos rope is used, the first one to the flame surface must be soaked in refractory mud.

(2) Water wall pipes, downcomers, headers, sewage pipes, drums, temperature measuring holes (tubes) and beams, etc., through the wall, leave expansion joints at the contact wall and the vertical and horizontal connections of the refractory brick furnace wall. It is better to wind with asbestos rope.

(3) The method of leaving the expansion joint of the furnace wall:

①. The method of retaining expansion joints at the corners is shown in Figure 9(a): the method of leaving the junction of 1/2 brick and 1 brick; Figure 9(b): the method of leaving the junction of 1 brick and 1 brick.

②. The method of setting expansion joints at the junction of the two ends of the demolition wall and the furnace wall is shown in Figure 10.

③. The vertical expansion joint staying method in the middle of the furnace wall is shown in Figure 11.

④. The method of setting expansion joints at the junction of the furnace roof and the two ends of the hanging arch and the furnace wall is shown in Figure 12.

⑤ The horizontal expansion joints of the furnace wall are generally made of special-shaped bricks. If there are no special-shaped bricks, the method shown in Figure 13 is used for masonry. When laying the horizontal expansion joint, the asbestos rope should be compressed; the height of the refractory bricks above the horizontal expansion joint should not exceed 1m, and the refractory bricks and red bricks will rise alternately to prevent the asbestos rope from being compressed and causing the furnace wall to tilt.

(4) The vertical expansion joint hangs the line for masonry, the wrong tooth is no more than 3mm, and the asbestos rope in the expansion joint is slightly larger than the remaining width of the expansion joint by 3~5mm, and it is pressed in at the same time during the masonry.

11. Refractory bricks and thermal insulation bricks are not allowed to wet the bricks, and the red bricks must be watered until the outside is dry and the inside is saturated before the red bricks are built.

12. It is not allowed to process bricks or walk on the masonry, and it is not allowed to face the processing surface of the bricks to the flame surface.

13. The surfaces of refractory bricks and red bricks must be jointed. Where the convection tube bundles are concentrated and where the boiler accessories are blocked, the ash ears must be scraped off along with the masonry.

Construction is often a link that companies tend to ignore. They always think that good products and good designs can guarantee the service life of the kiln. In the national standard, there are strict regulations on the construction of rotary kiln, as follows: