- 12

- Feb

How to build the refractory bricks of the boiler?

Olovga chidamli g’ishtlarni qanday qurish kerak qozon?

1. Qurilish bosqichlari pastdan yuqoriga va ichkaridan tashqariga tamoyiliga muvofiq amalga oshiriladi. Yuqori tamburning pastki qismi va konveksiya trubkasi to’plami oralig’i olov plitasi yuqoridan pastgacha quyiladi.

2. Olovli devor yuqori havo o’tkazmaydigan talablarga ega va kul bo’g’inlarining to’liqligi: qizil g’isht 85% dan kam emas; refrakter g’ishtlar 90% dan kam emas. Qizil g’ishtli g’isht uchun siqish usuli, o’tga chidamli g’isht uchun esa qirqish usuli qo’llaniladi.

3. Olovli pechning pastki qismini toshlash:

(1) Pechning tagini yotqizishdan oldin poydevor tekislanishi kerak va o’choqning pastki qismi bilan aloqa qiladigan atrofdagi tekis devorlar birinchi navbatda qurilishi kerak va balandligi o’choq tagining yuzasidan taxminan balandroq bo’lishi kerak. Keyin pechning pastki qismini qurishdan oldin to’g’ri devorga o’choq pastki qismining gorizontal chizig’ini (ko’p qatlamli duvarcılık bo’lsa, qatlamlar soni bilan birga) belgilang.

(2) Olovli pechning pastki qismi bir necha qatlamli g’ishtlardan tashkil topgan bo’lsa, g’ishtning yuqori va pastki qatlamlari va bir xil g’isht qatlami stagdalangan holda, g’ishtning ko’p qatlamli g’ishtlarining uzun tomonlari qatlam bilan amalga oshirilishi kerak. cüruf yoki gazning oqim yo’nalishiga perpendikulyar.

(3) In high-temperature areas and furnace bottoms that often need to be overhauled, an expansion gap should be left at the contact between the furnace bottom and the straight wall, and asbestos rope or pad asbestos board should be embedded in the gap.

4. Kul paqirini toshlash (qiyalik devor bilan birga):

(1) Kul paqirini qurishdan oldin, chizmalarga ko’ra, birinchi navbatda gorizontal markaz chizig’ini toping va har bir kul paqirining uzunlamasına markaz chizig’ini va qalin cürufda old va orqa tekis devorlarning tashqi qirralarini topish uchun gorizontal o’rta chiziqdan foydalaning. chelak, so’ngra balandlikni ikkala uchiga asoslang. Vertikal markaz chizig’ini kul idishining pastki qismiga oching va o’lchamni kul idishining pastki qismiga o’rnating. Vertikal yordamchi chiziqni ochgandan so’ng, ishlab chiqarilgan uchburchak shablonini ishlating (chizmadagi eğimli devorning nishabi bo’yicha qilingan) va poydevor stendining ikkala uchida eğimli devorning yon chizig’ini torting. Yuzaki. Eğimli devorning pastki qismida (1-rasmda ko’rsatilganidek) uchburchak to’siqni qilish uchun refrakter betonning bir xil materialidan foydalaning va tekis devorni tekislang. Vertikal, gorizontal va eğimli devorlarning birlashmasidagi uchburchak to’siq ham xuddi shu materialning refrakter beton bilan quyilishi kerak. Nishabli devorlarni g’isht bilan qoplashga o’ting.

(2) Kul paqirini qurishda birinchi navbatda gorizontal va keyin vertikalni quring; moyil devor va to’g’ri devor hosil bo’lganda, birinchi navbatda tekis devorni, keyin esa moyil devorni quring.

(3) Eğimli devorning orqa tomonida poydevor qo’llab-quvvatlashi mavjud bo’lganda, g’isht va poydevor orasidagi aloqa yuzasida ohak to’la bo’lishi kerak; Shlakli bo’lgandan so’ng, shlakni siqish kerak.

5. Masonry of straight walls:

(1) The straight walls around the boiler are composed of refractory bricks, thermal insulation bricks (or thermal insulation layer), and red bricks. The order of masonry construction is to build refractory bricks first, then thermal insulation bricks (or paste insulation boards or felt), and finally red bricks. For example, when the hot joint between the refractory brick and the red brick is filled, the filler should be filled every 3 to 4 layers of the red brick, and the filling should be dense.

(2) To’g’ri devorni qurishda uni o’choq devorining burchagiga qo’yish kerak. To’g’ri qismning ikki uchi 2 ~ 3 qatlamli boshlar bilan o’ralgan bo’lishi kerak va gorizontal chiziqni ushlab turish kerak. Ohak bo’g’inlarini qurish, kengaytiruvchi bo’g’inlarni joyida qoldiring, vertikal kengaytiruvchi bo’g’inlarni asbest arqonlarini osib qo’ying va devorga o’tishdan oldin asbest panellarini po’lat ramka jabhasiga yopishtiring.

(3) To’g’ridan-to’g’ri devor devorlarining g’ishtli usuli: 1/2 g’ishtli qalin devor staggerli bo’g’inlarni va 1/2 g’isht uzunligidagi toshni qabul qiladi; 1 g’isht va qalin devor yuqorida bir yuqori va bir tekis yoki qulf paketi duvarcılık usuli qabul qiladi. 1 g’isht va 1 g’isht qalin g’ishtli g’ishtning yuqori yoki pastki qatlami yuqori yoki yon devor bo’lishi kerak.

(4) Olovli devorning har ikki tomoni ishchi yuzalar bo’lsa (qalinligi 1 g’isht yoki undan kam bo’lgan devorlardan tashqari), ikkala tomon ham bir vaqtning o’zida yotqizilishi kerak.

(5) Suv bilan sovutilgan devor sarlavhasi va quvur tomoni va devordan o’tuvchi quvur tomonining toymasin tayanchi mahkamlanmasligi kerak va suv bilan sovutilgan devorning tortish kancasidagi maxsus shakldagi g’isht tiqilib qolmasligi kerak. suv bilan sovutilgan devorning quloq plitasi.

(6) Olovga chidamli g’ishtlar va qizil g’ishtlar yig’ilganda, o’tga chidamli g’ishtlar 6 dan 8 qatlamli g’isht balandligi bilan qurilganda, gorizontal yo’nalish bo’ylab har 1 dan 1.5 m gacha, 115 mm uzunlikdagi cho’zilgan g’ishtlarni tashqi devorga cho’zish kerak. qizil g’ishtlar. Kuchli g’ishtlarni bir xil qatlamda uzib qo’yish kerak, yuqori va pastki qatlamlar esa stagda bo’lishi kerak.

(7) When building the outer wall of red bricks, vent holes must be provided, and the distribution of the reserved space should be even. One can be reserved at about 2m2 and buried with DN15~20 black iron pipes (in the case of unavoidable circumstances, use reserved 60 ×120mm hole method). Boilers with grate start to be set up when the grate is flush; boilers without grate start to be set up at an elevation of about 1m, and the highest point of the insulation seam must also be set up, and the furnace shall be blocked with temperature-resistant materials immediately after the oven is completed.

6. Olovli devor teshiklari, inspeksiya teshiklari va boshqalarning toshlari ichki devorning o’tga chidamli g’ishtlari tashqi devorning qizil g’ishtlariga kirib boradigan devor usulini qo’llaydi (2-rasmga qarang). Teshikning (teshikning) ustki qoplamasi loyihasi zarur bo’lganda, toshni loyihalash talablariga muvofiq qurish kerak, agar loyiha talab qilinmasa, tosh quyidagi tartibda qurilishi kerak:

(1) The width of the hole (hole) in the wall is less than or equal to 450mm. If the span is not large, the solid platform method can be used to replace the small arch with a flat brick layer. The masonry method is shown in Figure 3. Each layer shall protrude ≤6mm from both sides into the opening until the opening is covered. The protruding length of each layer and the same layer shall be the same.

(2) The width of the opening (hole) in the wall ≤250mm can be covered by processing bricks. The masonry method is shown in Figure 4.

(3) Devordagi teshikning kengligi> 450 mm kengligi kamarga aylanadigan tosh bilan qoplanishi kerak.

7. Masonry of arch and vault:

(1) The tire mold radius and radian production size required for arch and vault masonry must meet the design requirements. The span of the tire mold is less than the actual span by 20~30mm, the surface is flat and smooth, and it has load-bearing materials and construction loads without deformation Ability.

(2) Kemerli g’ishtdan oldin, kamar oyoqli g’ishtlarning orqasidagi toshni tugatish kerak va devor faqat tekshiruvdan o’tgandan keyin qurilishi mumkin. Ark-oyoq g’ishtlaridan keyin issiqlik izolyatsiya qiluvchi o’tga chidamli g’isht yoki g’ishtli suv o’tlari tuproqli g’ishtlarni qurishga yo’l qo’yilmaydi.

(3) Before the arch top is built, the arch toe beam and the frame column must be close together. Before laying the arch of the adjustable frame, the frame and the tie rods must be adjusted and fixed, and passed the inspection.

(4) Ark va tonoz devoridan oldin, avval shinalar qolipini o’rnating, balandligi va holatini tekshiring, uni mahkam o’rnating va keyin old devorni bajaring. Old g’ishtning maqsadi, asosan, ohak bo’g’inlarini sozlash va kamar g’ishtlarini yig’ishdir. Ark devorlarining sifati va staggered bo’g’inlari talablariga javob beradigan model. kamar g’isht yig’ish tartibi talablarga javob so’ng, g’isht yuzlari g’isht tartibiga ko’ra raqamlangan va keyin olib tashlangan, shakl 5 da ko’rsatilganidek, tosh bir vaqtning o’zida kamar oyog’idan markazga nosimmetrik qurilgan bo’lishi kerak. Duvarcılıkni teskari tomonga burish qat’iyan man etiladi.

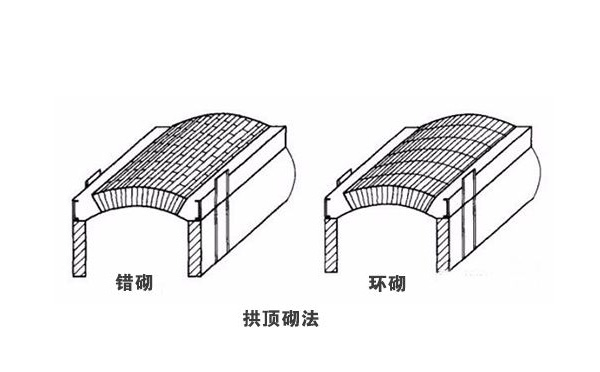

(5) Unless there are special regulations, the arches and vaults shall be laid in staggered joints, and arches and vaults with different spans can be laid in rings. In the case of staggered joint masonry, when the length of the longitudinal joint is longer than 1 meter, the masonry must be drawn with a line.

(6) Lock bricks must be installed in the masonry of the arch and vault top. The depth of the built-in lock bricks is 2/3~3/4 of the thickness of the arch and vault top. As shown in Figure 6, the lock depth of the same arch must be the same. , When locking in, it should be from the tighter lock to the looser. In the wall, several adjacent arches and the lock bricks of the arch roof must be driven in at the same time to prevent the deformation of the adjacent arches.

(7) Qulf g’ishtlari teng va nosimmetrik tarzda taqsimlanadi. <3 m masofada bitta blokli g’isht ichiga haydab, > 3 m gacha bo’lgan 3 ta qulflangan g’ishtni haydang. Qulflanganda siz bolg’achadan foydalanishingiz mumkin, lekin u yog’och taxta bilan to’ldirilgan bo’lishi kerak.

(8) It is not allowed to use bricks that have a thickness of more than 1/3 or cut the long side to make the large surface into a wedge shape as a lock brick.

(9) For the processed bricks that are leveled on the upper part of the arch and the vault, the high temperature area or the surface of the external wall can be leveled by brick processing, and the low temperature area can be leveled by the same material of refractory concrete.

8. Upside-down masonry:

(1) teskari toshni burishda ichkarida va tashqarisida ikkita yoy shaklidagi taxtalar tayyorlanadi. Ichki yoy plitasi aylanish radiusiga ko’ra amalga oshiriladi; tashqi kamon plitasi ichki radius va aylanadigan g’ishtning qalinligi bilan amalga oshiriladi.

(2) teskari aylanishni qurishda, aylanishning pastki markaziy chizig’i kamon shaklidagi plitaga asoslanadi va pastki qismi quriladi. Odatda, g’ishtning uzunligi 5 ~ 7 aylanadigan g’ishtlarga mos kelishi mumkin, keyin siz teskari qurishni boshlashingiz mumkin. Qaytib, so’ngra nosimmetrik tarzda teskari tomonning pastki qismining o’rtasidan pastga, har ikki tomonga teskari quring. Qurilishni boshlaganda siljish yoki bo’shashmaslik uchun juda qattiq urmang. Invertli vintning pastki qismida 5 ~ 7 ta g’isht qurilgandan so’ng, aylanuvchi g’isht yuzasiga ichki yoy shaklidagi taxta o’rnatiladi va g’ishtlarni g’ishtlarni aylantirish tartibida har ikki tomonga nosimmetrik tarzda yotqiziladi va keyin g’ishtlarni qayta ishlash. Duvarcılık ketma-ketligi 7-rasmda ko’rsatilgan.

(3) When turning to 1/2 circle, the upper 1/2 adopts arch and vault masonry. When locking the bricks, turn the bricks around 1/2 of the upper vector height and then lock the bricks after the masonry is finished, as shown in Figure 8.

9. Masonry of hanging bricks and demolition of flame walls:

(1) Hanging bricks and removing flame walls follow the principle of building from low to high, from the middle to both sides.

(2). Osilgan g’ishtlar va olovni o’chirish devorlarini qurish uchun g’ishtlarni qayta ishlash kerak bo’lganda, osilgan g’ishtlarning osilgan teshiklarining bo’shligi 5 mm dan oshmasligi kerak va olovni o’chirish devorlari qalinligi 90 dan kam bo’lmasligi kerak. %. Osilgan g’ishtlarning asosiy kuch-quvvatli qismlarida yoriqlar bo’lmasligi kerak.

(3) mahkamlash murvatlari teshiklari bo’lgan maxsus shakldagi g’ishtlar uchun, sinov yotqizish uchun birinchi navbatda quruq qatorlar va trubkadagi murvat teshiklarining holatini belgilagandan so’ng, mahkamlash murvatlarini payvandlash mumkin. Olovga chidamli g’ishtlarga shikast etkazmaslik uchun duvarcılık paytida yong’oqlar juda qattiq tortilmasligi kerak va murvat teshiklari o’tga chidamli beton bilan to’ldirilishi kerak.

10. The expansion joints of the furnace wall are left:

(1) o’choq devoridagi kengaytiruvchi bo’g’inlarning joylashishi va shakli dizayn talablariga mos keladi. Kengligi dizayn talablaridan kichikroq bo’lishiga yo’l qo’yilmaydi va singan g’isht kabi qattiq narsalarning bo’g’inlarga tushishiga yo’l qo’yilmaydi. Kengaytirish bo’g’inidagi qadoqlash dizayn talablariga muvofiq mahkam o’ralgan. Asbest arqondan foydalanilganda, olov yuzasiga birinchi bo’lib o’tga chidamli loy bilan namlangan bo’lishi kerak.

(2) Suv devori quvurlari, pastga tushadigan quvurlar, sarlavhalar, kanalizatsiya quvurlari, barabanlar, haroratni o’lchash teshiklari (quvurlar) va to’sinlar va boshqalar devor orqali aloqa devorida va o’tga chidamli g’ishtli pechning vertikal va gorizontal ulanishlarida kengaytirish bo’g’inlarini qoldiradi. devor. Asbest arqon bilan shamol qilish yaxshiroqdir.

(3) Olovli devorning kengaytiruvchi bo’g’inidan chiqish usuli:

①. The method of retaining expansion joints at the corners is shown in Figure 9(a): the method of leaving the junction of 1/2 brick and 1 brick; Figure 9(b): the method of leaving the junction of 1 brick and 1 brick.

②. Buzuvchi devor va o’choq devorining ikki uchining birlashmasida kengaytiruvchi bo’g’inlarni o’rnatish usuli 10-rasmda ko’rsatilgan.

③. Pech devorining o’rtasida vertikal kengaytiruvchi birikmaning qolishi usuli 11-rasmda ko’rsatilgan.

④. Pech tomi va osilgan kamarning ikki uchi va o’choq devorining birlashmasida kengaytiruvchi birikmalarni o’rnatish usuli 12-rasmda ko’rsatilgan.

⑤ Pech devorining gorizontal kengayish bo’g’inlari odatda maxsus shakldagi g’ishtlardan yasalgan. Maxsus shakldagi g’ishtlar bo’lmasa, 13-rasmda ko’rsatilgan usul duvarcılık uchun ishlatiladi. Gorizontal kengaytirish birikmasini yotqizishda asbest arqonini siqish kerak; gorizontal kengaytiruvchi birikma ustidagi refrakter g’ishtlarning balandligi 1 m dan oshmasligi kerak va asbest arqonining siqilishiga va o’choq devorining egilishiga olib kelishiga yo’l qo’ymaslik uchun refrakter g’isht va qizil g’isht navbatma-navbat ko’tariladi.

(4) Vertikal kengaytirish bo’g’ini devor uchun chiziqni osib qo’yadi, noto’g’ri tish 3 mm dan oshmaydi va kengaytiruvchi bo’g’indagi asbest arqon kengaytiruvchi bo’g’inning qolgan kengligidan 3 ~ 5 mm ga bir oz kattaroqdir va u bosiladi. bir vaqtning o’zida duvarcılık paytida.

11. Refractory bricks and thermal insulation bricks are not allowed to wet the bricks, and the red bricks must be watered until the outside is dry and the inside is saturated before the red bricks are built.

12. It is not allowed to process bricks or walk on the masonry, and it is not allowed to face the processing surface of the bricks to the flame surface.

13. Olovga chidamli g’isht va qizil g’ishtlarning sirtlari birlashtirilgan bo’lishi kerak. Konveksiya trubkasi to’plamlari to’plangan joyda va qozon aksessuarlari bloklangan joylarda, kul quloqlari tosh bilan birga qirib tashlanishi kerak.

Qurilish ko’pincha kompaniyalar e’tibordan chetda qoladigan aloqadir. Ular har doim yaxshi mahsulotlar va yaxshi dizaynlar pechning xizmat qilish muddatini kafolatlashi mumkin deb o’ylashadi. Milliy standartda aylanadigan pechni qurish bo’yicha qat’iy qoidalar mavjud: