- 12

- Feb

Momwe mungamangire njerwa za refractory za boiler?

Momwe mungamangire njerwa zomangira za kukatentha?

1. The construction steps are carried out in accordance with the principle of from bottom to top and from inside to outside. The lower part of the upper drum and the convection tube bundle interval flame plate are poured from top to bottom.

2. The furnace wall has high air-tightness requirements, and the fullness of ash joints: red bricks are not less than 85%; refractory bricks are not less than 90%. The squeezing method is used for red brick masonry, and the scraping method is used for refractory brick masonry.

3. Kumanga kwa ng’anjo pansi:

(1) Before the furnace bottom is laid, the foundation should be leveled, and the surrounding straight walls in contact with the furnace bottom should be built first, and the height should be approximately higher than the surface of the furnace bottom. Then mark the horizontal line of the furnace bottom (in the case of multi-layer masonry, together with the number of layers) on the straight wall before the furnace bottom can be built.

(2) When the furnace bottom is composed of multiple layers of bricks, the masonry should be carried out layer by layer, with the upper and lower layers and the same layer of bricks staggered, and the long sides of the most surface layer bricks are perpendicular to the flow direction of slag or gas.

(3) In high-temperature areas and furnace bottoms that often need to be overhauled, an expansion gap should be left at the contact between the furnace bottom and the straight wall, and asbestos rope or pad asbestos board should be embedded in the gap.

4. Masonry of ash bucket (including inclined wall):

(1) Musanayambe kumanga chidebe phulusa, choyamba kupeza yopingasa centerline malinga ndi zojambula, ndi ntchito yopingasa pakati mzere kupeza longitudinal centerline aliyense chidebe phulusa ndi m’mphepete akunja a kutsogolo ndi kumbuyo molunjika makoma pa wandiweyani slag. chidebe, ndiyeno khazikitsani malo okwera kumapeto onse awiri. Tulukani mzere woyimirira wapakati mpaka pansi pa chopopera phulusa, ndikuyika kukula kwake pansi pa chopondera phulusa. Pambuyo potulukira mzere wothandizira wokhazikika, gwiritsani ntchito template yopangidwa ndi makona atatu (yopangidwa molingana ndi kutsetsereka kwa khoma lokhazikika pajambula), ndipo jambulani mzere wam’mbali wa khoma lokhazikika pa malekezero onse a maziko a maziko. Pamwamba. Gwiritsani ntchito zinthu zomwezo za konkire yotsutsa kuti mupange katatu kumbuyo kwa khoma lokhazikika (monga momwe tawonetsera pa Chithunzi 1) ndikuyendetsa khoma lolunjika. The triangular kubweza pa mphambano of ofukula, yopingasa ndi kupendekeka makoma adzathiridwanso ndi refractory konkire wa zinthu zomwezo. Pitirizani ku makoma otsetsereka.

(2) When building the ash bucket, first build the horizontal and then the vertical; when the inclined wall and the straight wall are formed, build the straight wall first and then the inclined wall.

(3) When there is foundation support on the back of the inclined wall, the mortar on the contact surface between the bricks and the foundation should be full; Once cinder, cinder must be compacted.

5. Masonry of straight walls:

(1) Makoma owongoka ozungulira chowotchera amapangidwa ndi njerwa zomangira, njerwa zotsekereza matenthedwe (kapena wosanjikiza wotsekera), ndi njerwa zofiira. Dongosolo la zomangamanga ndikumanga njerwa zomangira kaye, kenako njerwa zotenthetsera (kapena kumata matabwa kapena zomverera), kenako njerwa zofiira. Mwachitsanzo, pamene chophatikizira chotentha pakati pa njerwa yotsutsa ndi njerwa yofiira chadzazidwa, chodzaza chiyenera kudzazidwa zigawo zitatu mpaka 3 za njerwa yofiira, ndipo kudzazidwa kuyenera kukhala wandiweyani.

(2) When building a straight wall, it must be placed at the corner of the furnace wall. The two ends of the straight section must be yarded with 2~3 layers of heads, and the horizontal line must be held. Build the mortar joints, leave the expansion joints in place, hang the vertical expansion joints asbestos ropes, and paste the asbestos panels on the steel frame facade before proceeding to masonry.

(3) Njira yomanga khoma yowongoka ndi: 1/2 khoma lokhuthala la njerwa limatenga malo olumikizirana ndi 1/2 kutalika kwa njerwa; 1 njerwa ndi khoma lokhuthala limagwiritsa ntchito pamwamba imodzi ndi njira imodzi yowongoka kapena yotsekera. Pamwamba kapena pansi pa njerwa ya njerwa imodzi ndi 1 njerwa zochindikala zizikhala za pamwamba kapena zam’mbali.

(4) When both sides of the furnace wall are working surfaces (except for walls with a thickness of 1 brick or less), both sides are to be laid at the same time.

(5) The water-cooled wall header and the pipe side and the sliding support of the pipe side passing through the masonry shall not be fixed, and the special-shaped brick at the pull hook of the water-cooled wall shall not jam the ear plate of the water-cooled wall.

(6) When the refractory bricks and red bricks are assembled, when the refractory bricks are built with 6 to 8 layers of brick height, every 1 to 1.5m along the horizontal direction, 115mm long stretched bricks must be extended to the outer wall of the red bricks. Tensioned bricks should be disconnected on the same layer, and the upper and lower layers should be staggered.

(7) When building the outer wall of red bricks, vent holes must be provided, and the distribution of the reserved space should be even. One can be reserved at about 2m2 and buried with DN15~20 black iron pipes (in the case of unavoidable circumstances, use reserved 60 ×120mm hole method). Boilers with grate start to be set up when the grate is flush; boilers without grate start to be set up at an elevation of about 1m, and the highest point of the insulation seam must also be set up, and the furnace shall be blocked with temperature-resistant materials immediately after the oven is completed.

6. Kumanga kwa khoma la ng’anjo, mabowo oyendera, ndi zina zotere zimagwiritsa ntchito njira ya zomangamanga kuti njerwa zotsutsa za khoma lamkati zilowerere ku njerwa zofiira za khoma lakunja (onani Chithunzi 2). Pamene chivundikiro chapamwamba chotsegulira (dzenje) chikufunika, zomangazo zimamangidwa molingana ndi zofunikira za mapangidwe, ndipo pamene mapangidwewo sakufunika, zomangamanga ziyenera kumangidwa motere:

(1) M’lifupi mwake bowo (dzenje) pakhoma ndi lochepera kapena lofanana ndi 450mm. Ngati danga silili lalikulu, njira yolimba ya nsanja ingagwiritsidwe ntchito m’malo mwa arch yaying’ono ndi wosanjikiza njerwa. Njira yopangira miyala ikuwonetsedwa mu Chithunzi 3. Chigawo chilichonse chidzatuluka ≤6mm kuchokera kumbali zonse ziwiri mpaka kutsegula mpaka kutsegula. Utali wotuluka wa wosanjikiza uliwonse ndi wosanjikiza womwewo ukhale wofanana.

(2) The width of the opening (hole) in the wall ≤250mm can be covered by processing bricks. The masonry method is shown in Figure 4.

(3) The width of the hole in the wall> 450mm width shall be covered by arch-rotating masonry.

7. Masonry of arch and vault:

(1) The tire mold radius and radian production size required for arch and vault masonry must meet the design requirements. The span of the tire mold is less than the actual span by 20~30mm, the surface is flat and smooth, and it has load-bearing materials and construction loads without deformation Ability.

(2) Before arch masonry, the masonry behind the arch-foot bricks must be completed, and the masonry can only be built after passing the inspection. After the arch-foot bricks, it is not allowed to build heat-insulating refractory bricks or brick algae earth bricks.

(3) Before the arch top is built, the arch toe beam and the frame column must be close together. Before laying the arch of the adjustable frame, the frame and the tie rods must be adjusted and fixed, and passed the inspection.

(4) Before the arch and vault masonry, first install the tire mold, check the elevation and position, fix it firmly, and then carry out pre-masonry. The purpose of pre-masonry is mainly to adjust the mortar joints and assemble the arch bricks. Model to meet the requirements of arch masonry quality and staggered joints. After the arch brick assembly arrangement meets the requirements, the brick faces are numbered according to the order of masonry and then removed, as shown in Figure 5. The masonry must be symmetrically built from the arch foot to the center at the same time. It is strictly forbidden to upside down the masonry.

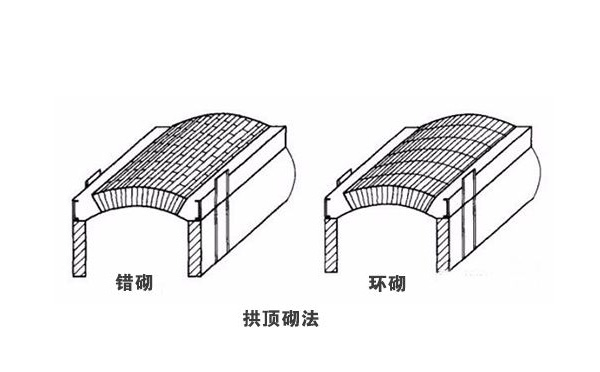

(5) Pokhapokha ngati pali malamulo apadera, zipilala ndi zipilala zidzayikidwa m’magulu osakanikirana, ndipo mazenera ndi zipilala zokhala ndi zosiyana zimatha kuikidwa mu mphete. Pankhani ya zomangamanga zosakanikirana, pamene kutalika kwa mgwirizano wautali ndi wautali kuposa mamita 1, zojambulajambula ziyenera kujambulidwa ndi mzere.

(6) Lock bricks must be installed in the masonry of the arch and vault top. The depth of the built-in lock bricks is 2/3~3/4 of the thickness of the arch and vault top. As shown in Figure 6, the lock depth of the same arch must be the same. , When locking in, it should be from the tighter lock to the looser. In the wall, several adjacent arches and the lock bricks of the arch roof must be driven in at the same time to prevent the deformation of the adjacent arches.

(7) Njerwa za loko zimagawidwa mofanana komanso molingana. Lowetsani njerwa yokhoma imodzi kutalika <3m, ndikuyendetsa njerwa zokhoma 3 kutalika> 3m. Mukhoza kugwiritsa ntchito nyundo kuti mulowetsemo pamene yakhoma, koma iyenera kukulungidwa ndi matabwa.

(8) Sizololedwa kugwiritsa ntchito njerwa zomwe zimakhala ndi makulidwe oposa 1/3 kapena kudula mbali yayitali kuti ikhale yozungulira ngati njerwa ya loko.

(9) For the processed bricks that are leveled on the upper part of the arch and the vault, the high temperature area or the surface of the external wall can be leveled by brick processing, and the low temperature area can be leveled by the same material of refractory concrete.

8. Zomanga mozondoka:

(1) Mapulani awiri ooneka ngati arc mkati ndi kunja amapangidwa akamakhota mozondoka. Chipinda chamkati cha arc chimapangidwa molingana ndi utali wa kuzungulira; mbale yakunja ya arc imapangidwa ndi radius yamkati kuphatikiza makulidwe a njerwa yozungulira.

(2) Pomanga kuzungulira mozondoka, mzere wapakati wapakati wozungulira umachokera ku slab yofanana ndi arc, ndipo gawo lapansi limamangidwa. Nthawi zambiri, kutalika kwa njerwa kumatha kukumana ndi njerwa zozungulira 5 ~ 7, ndiye mutha kuyamba kumanga mozondoka. kuzungulira, ndiyeno symmetrically kumanga mozondoka kuchokera pakati pa pansi mozondoka mpaka mbali zonse. Osagunda kwambiri mukamayamba kumanga kuti musasunthe kapena kumasuka. Pambuyo pa njerwa za 5 ~ 7 kumunsi kwa screw inverted, bolodi lamkati lokhala ngati arc limakhazikika pamwamba pa njerwa yozungulira, ndipo njerwa zimayikidwa mozungulira mbali zonse ziwiri motsatana ndi kuzungulira njerwa kenako. kukonza njerwa. Kutsatizana kwa masonry kukuwonetsedwa mu Chithunzi 7.

(3) Mukatembenukira ku bwalo la 1/2, 1/2 yakumtunda imatengera zomangira ndi zomangira. Mukatseka njerwa, tembenuzirani njerwa mozungulira 1/2 ya utali wa valavu yakumtunda ndikutseka njerwayo akamaliza kumanga, monga momwe chithunzi 8 chikusonyezera.

9. Kumanga njerwa zolendewera ndi kugwetsa makoma amoto:

(1) Hanging bricks and removing flame walls follow the principle of building from low to high, from the middle to both sides.

(2). Pamene njerwa ziyenera kukonzedwa pomanga njerwa zolendewera ndi makoma ochotsa moto, kuchotsedwa kwa mabowo opachika a njerwa zopachikidwa sikuyenera kukhala kwakukulu kuposa 5mm, ndipo makulidwe a makoma ochotsa moto sangakhale osachepera 90. %. Pasakhale ming’alu pazigawo zazikulu zomangira za njerwa zopachikidwa.

(3) Kwa njerwa zokhala ndi mawonekedwe apadera okhala ndi mabowo okonza, mzere woyamba wowuma ndi wosanjikiza poyesa kuyika, ndipo mutalemba malo a mabowo a bawuti pa chitoliro, ma bolts okonzekera amatha kuwotcherera. Mtedza sayenera kumangika mwamphamvu kwambiri panthawi yomanga kuti zisawononge njerwa zowonongeka, ndipo mabowo a bawuti ayenera kudzazidwa ndi konkire yotsutsa.

10. Zolumikizana zakukulitsa khoma la ng’anjo zatsala:

(1) The location and form of the expansion joints on the furnace wall are in accordance with the design requirements. The width is not allowed to be smaller than the design requirements, and hard objects such as broken bricks are not allowed to fall into the joints. The packing in the expansion joint is tightly packed according to the design requirements. When asbestos rope is used, the first one to the flame surface must be soaked in refractory mud.

(2) Water wall pipes, downcomers, headers, sewage pipes, drums, temperature measuring holes (tubes) and beams, etc., through the wall, leave expansion joints at the contact wall and the vertical and horizontal connections of the refractory brick furnace wall. It is better to wind with asbestos rope.

(3) Njira yosiyira cholumikizira cholumikizira khoma la ng’anjo:

①. The method of retaining expansion joints at the corners is shown in Figure 9(a): the method of leaving the junction of 1/2 brick and 1 brick; Figure 9(b): the method of leaving the junction of 1 brick and 1 brick.

②. Njira yokhazikitsira zilumikizidwe zowonjezera pamphambano za mbali ziwiri za khoma lakugwetsa ndi khoma la ng’anjo ikuwonetsedwa mu Chithunzi 10.

③. Njira yokulirapo yolumikizirana pakati pa khoma la ng’anjo ikuwonetsedwa pa chithunzi 11.

④. The method of setting expansion joints at the junction of the furnace roof and the two ends of the hanging arch and the furnace wall is shown in Figure 12.

⑤ Magulu opingasa a khoma la ng’anjo nthawi zambiri amapangidwa ndi njerwa zapadera. Ngati palibe njerwa zooneka mwapadera, njira yomwe ikuwonetsedwa mu Chithunzi 13 imagwiritsidwa ntchito pomanga. Poyala chopingasa cholumikizira cholumikizira, chingwe cha asibesitosi chiyenera kukakamizidwa; kutalika kwa njerwa zokanira pamwamba pa chopingasa cholumikizira sichiyenera kupitirira 1m, ndipo njerwa zokanira ndi njerwa zofiira zidzakwera mosinthana kuti ziteteze chingwe cha asibesitosi kuti chisapanikizidwe ndikupangitsa kuti khoma la ng’anjo lipendekeke.

(4) Cholumikizira chowongoka chokhazikika chimapachikidwa pamzere womanga, dzino lolakwika silipitilira 3mm, ndipo chingwe chaasibesitosi chokulirapo chimakhala chokulirapo pang’ono kuposa m’lifupi mwake mwa 3 ~ 5mm, ndipo chimakanikizidwa. pa nthawi yomanga nyumba.

11. Njerwa zokanira ndi njerwa zosungunulira kutentha siziloledwa kunyowetsa njerwa, ndipo njerwa zofiira ziyenera kuthiriridwa mpaka kunja kuuma ndipo mkati mwake mukhuta njerwa zofiira zisanamangidwe.

12. It is not allowed to process bricks or walk on the masonry, and it is not allowed to face the processing surface of the bricks to the flame surface.

13. The surfaces of refractory bricks and red bricks must be jointed. Where the convection tube bundles are concentrated and where the boiler accessories are blocked, the ash ears must be scraped off along with the masonry.

Construction is often a link that companies tend to ignore. They always think that good products and good designs can guarantee the service life of the kiln. In the national standard, there are strict regulations on the construction of rotary kiln, as follows: