- 21

- Sep

Qalabka kuleylinta rotor rotor-ka iyo jaakada kuleylka usheeda dhexe

Rotor matoor Qalabka kululeynta la-galinta iyo jaakadda kululaynta usheeda dhexe

Rotor-ka aan shafka lahayn ee matoorku wuxuu ka samaysan yahay go’yaal bir ah oo silikon waxaana lagu shubay dhammaan dareeraha aluminiumka. Ka dib marka lagu kululeeyo heerkul gaar ah, waxaa lagu daboolaa kuleyl-kuleelka usheeda dhexe ee warshadaysan. Qaboojinta ka dib, rotor-ka aan shaftirka lahayn ayaa la isku hagaajinayaa shafka si uu u noqdo jiir. Rotor qafis

Waagii hore, inta badan dhirta wax soo saarku waxay isticmaali jireen foornooyinka ololka ama foornooyinka iska caabinta si ay u kululeeyaan rotors-ka aan shafka lahayn. Si kor loogu qaado tayada kuleyliyaha iyo wax soo saarka, loona yareeyo isticmaalka tamarta iyo kharashyada wax soo saarka, qalabka kuleylinta induction ee rotors-ka aan shaftirka lahayn ayaa la sameeyay waxaana lagu gaaray natiijooyin wanaagsan. Natiijooyin wanaagsan, hadda loo isticmaalo wax soo saarka

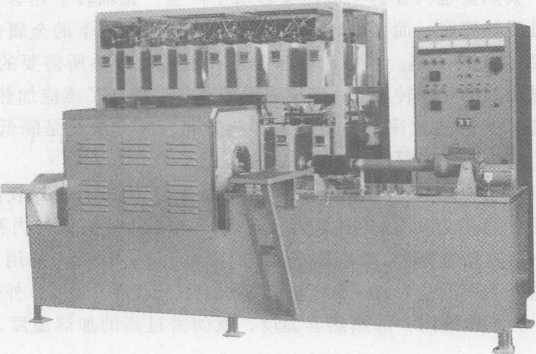

Inta jeer ee hadda jira ayaa lagu doortaa iyadoo loo eegayo dhexroorka rotor-ka shaftless. Rotor-ka aan shaftirka lahayn ee matoorka guud, qalabka kuleyliyaha soo noqnoqda ee soo noqnoqda tamarta ayaa loo isticmaalaa dhexroorkiisa weyn; matoorada yar yar ee aan shaftirka lahayn, qalabka kuleylinta soo noqnoqda ee inta jeer ee dhexdhexaadka ah ayaa la isticmaalaa. Jaantuska 12-24 waxa uu tusinayaa qalab dhamaystiran oo rotor-ka ah oo soo noqnoqda tamarta rotor-ka, oo ay ku jiraan qalabka kulaylinta soo noqnoqda tamarta, armaajooyinka korantada, iyo armaajooyinka korantada.

Jaantus 12-24 Qalab kuleyliyaha inta jeer ee rotor-ka aan shaadhka lahayn

1. Habka cabbiraadaha usheeda dhexe ee rotor-ka kulul ee aan shaadhka lahayn

Habka usheeda dhexe ee rotor-gacanta kulul waxay inta badan ku salaysan tahay faragelinta ugu badan ee u dhaxaysa usheeda dhexe iyo godka gudaha ee rotor shaftless si loo go’aamiyo heerkulka kulaylka ee rotor shaftless. Heerkulka kulaylka ugu yar (la’aanteed) waa halka H ——shaft iyo Faragelinta ugu badan ee u dhaxaysa dhexroorka gudaha ee rotor-ka usha lahayn (mm); D ——dhexroorka gudaha ee rotor-ka aan shaftirka lahayn (mm); K—— isku xidhka fidinta tooska ah ee xaashida birta silikoon. K= (11 ~13) 10-6

Si loo fududeeyo gacanta kulaylka ee rotor shaftless on usheeda dhexe, iyo in la tixgeliyo dhimista heerkulka inta lagu guda jiro habka kulaylka, heerkulka kulaylka ee rotor shaftless waa in daraasiin darajo ka sarreeya heerkulka kulaylka ugu yar, taas oo ku xidhan tahay. xaaladda gaarka ah.

2. Xulashada inta jeer ee hadda jirta ee qalabka kuleyliyaha induction

Wax ku oolnimada qalabka kuleyliyaha induction induction ee workpiece asal ahaan waxaa lagu go’aamiyaa xulashada saxda ah ee inta jeer ee hadda jira. Moolka dhexgalka ee p hadda – caabbinta qaybta shaqada (ft • cm); f—dareenka qaraabada ee qaybta shaqada;

Waxaa laga arki karaa qaacidada kor ku xusan in marka resistivity p iyo qaraabo permeability ee workpiece yihiin joogto ah, sida inta jeer ee hadda f kordho, qoto dheer lays ee hadda on workpiece noqdo yar iyo yar. Guud ahaan waxa la rumaysan yahay in wakhtigan la keenay uu ku socdo kaliya lakabka wax galka ah ee hadda jira, kulaylkiisuna waxa uu ka dhashaa oo kaliya lakabkan wax gala. Usheeda dhexe rotor kulaylka shaftless waxay u baahan tahay godka gudaha ee rotor shaftless in thermally balaadhiyo, iyo biraha ka hooseeya qoto dheer lays hadda ee rotor shaftless la kululayn karaa oo kaliya ka lakabka kululaynta hab kulaylka. Marka inta jeer ee hadda jira uu sarreeyo, wakhtiga loo baahan yahay wareejinta kulaylku wuu dheer yahay, taas oo kordhisa kulaylka ku faafaya dhexdhexaadiyaha ku hareeraysan rotor-ka kuleylka ah, oo yareynaya waxtarka kulaylka ee qalabka kuleyliyaha induction. Si loo hagaajiyo waxtarka kulaylka ee qalabka kuleyliyaha induction, wakhtiga kuleylka waa in la soo gaabiyo. Habka waa in la yareeyo inta jeer ee hadda iyo in la kordhiyo qoto dheer lays hadda on workpiece ah.

Maaddaama xaashida birta silikoon ee rotor-ka aan shafka lahayni ay leedahay awood magnetic wanaagsan, awooddeeda qaraabada ah waa mid sare, qoto dheerna galinta hadda waa mid yar. Marka rotor-ka aan shaftirka lahayn lagu kululeeyo 1000Hz, farqiga heerkulka u dhexeeya dusha sare iyo daloolka gudaha waa 100 -150 ^, taas oo ah, marka daloolka gudaha uu yahay 250Y, heerkulka dusha sare waa 350-400 nil. Tusaale ahaan, haddii inta jeer ee tamarta kulaylinta soo noqnoqda hadda la isticmaalo, farqiga heerkulka u dhexeeya dusha gudaha iyo dibadda waa 20 ~ 50 dheer. Haddii heerkulka daloolka gudaha uu yahay 250Y iyo heerkulka dusha sare uu yahay 270 ~ 300 ^ o, kulaylku aad buu u sarreeyaa si loo gaaro heerkulka jaakada kuleyliyaha isku mid ah. Ku habboon badbaadinta awoodda.