- 28

- Jan

Uteuzi wa njia ya baridi na nguvu introduktionsutbildning joto elbow quenching vigezo mchakato

Uteuzi wa njia ya baridi na nguvu introduktionsutbildning joto elbow quenching vigezo mchakato

The process parameters of induction heating and quenching mainly refer to the austenitizing temperature and the quenching cooling method. Among them, the selection of austenitizing temperature is mainly based on obtaining fine grain size, good low temperature toughness, and higher yield strength and tensile strength. These properties also need to be combined with the tempering process to determine. Bend pipes of different strength grades have different requirements for the above-mentioned performance. Take the X80 elbow as an example to illustrate the method of determining its quenching process parameters. The chemical composition of the test steel pipe and elbow steel is listed in Table 10-1.

Jedwali 10-1 Muundo wa kemikali wa mabomba ya chuma na viwiko vya kupima

Sampuli ya muundo wa kemikali (sehemu ya wingi)/%

C Si Mn PS Cr Mo Ni Nb V Ti Cu B Al

Steel pipe A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 — 0.03

B 0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

Mwili wa bomba la kiwiko 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. 0001 0. 03

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. 0001 0. 02

First of all, use the steel pipes A and B, using the traditional electric furnace heating method in the laboratory to complete the following relevant test contents.

(1) The relationship between quenching temperature and austenite grain size The relationship between heating temperature and grain size is shown in Figure 10-2. Under test conditions, austenitize at 1000°C. After water quenching and tempering at 500°C for 1h, the resulting grain size is as follows. Under production conditions, the hot elbow is water-cooled and subjected to 500°C , The grain size after heat preservation for 1h is 13km. Under the test conditions and production conditions, the obtained austenite grain size is very close. From the perspective of the quenching heating temperature and the grain size of the elbow after the final treatment, it should be feasible to select the upper limit of the quenching temperature to be about 1000°C. The thickness of the grain size has a greater impact on the yield strength and low temperature toughness of the elbow. Under normal conditions, the finer the grain size

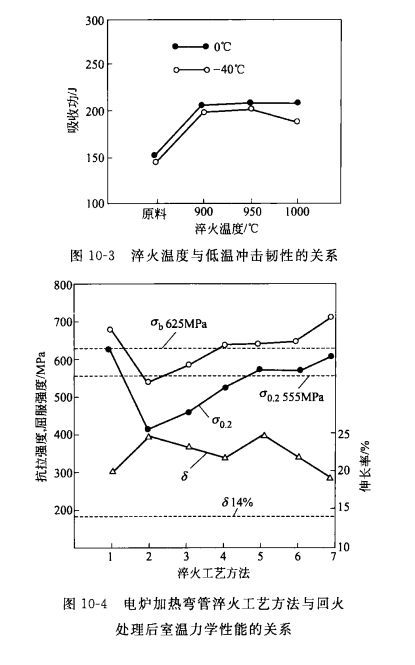

Ndogo, nguvu ya mavuno ya juu ya kiwiko, ndivyo ugumu wa hali ya chini ya joto. (2) Uhusiano kati ya halijoto ya kuzima na ushupavu wa athari wa halijoto ya chini Mchoro 10-3 unaonyesha uhusiano kati ya halijoto ya kuzima na ushupavu wa athari wa halijoto ya chini katika 0°C na -40°C. Kwa 0°C, uthabiti wa athari wa 900~1000°C haubadilika sana; kwa joto la 40 ° C, wakati joto la kuzima ni la juu kuliko 950 ° C, ugumu wa athari huelekea kupungua. Kutoka kwa hali iliyo hapo juu, joto la kuzima la kiwiko haipaswi kuzidi 950 ℃ iwezekanavyo.

Uhusiano kati ya mchakato wa kuzima na mali za mitambo Mchakato wa kuzimisha ni pamoja na joto la kuzima, kiwango cha baridi (kati ya baridi). Athari juu ya nguvu na urefu wa chuma huonyeshwa kwenye Mchoro 10-4. Yaliyomo katika michakato saba ya kuzima katika Mchoro 10-4 yameorodheshwa katika Jedwali 10-2. Mikondo mitatu katika Mchoro 10-4 mtawalia inawakilisha mahitaji ya chini kabisa ya δb, δ0.2, na δ ya mabomba ya chuma ya daraja la X80 katika kiwango cha APIspec 5L. Kutoka kwa data katika Mchoro 10-4, inaweza kuonekana kuwa nguvu za maji zilizozimwa na sampuli za hasira, ikiwa ni pamoja na elongation (ona Mchoro 10-4), inakidhi mahitaji ya kiwango; wakati sampuli za hewa-kilichopozwa na mafuta-kilichopozwa na hasira Nguvu zake ni za chini kuliko mahitaji ya kawaida. Inaweza kuonekana kuwa, kwa mtazamo wa halijoto ya kuzima, mchakato wa kuzima kwa maji yaliyopozwa kwa 900-1000℃ unaambatana na matibabu ya joto ya chuma ya kukunja ya daraja la X80. Jedwali 10-2 Mchakato wa matibabu ya kuzima na kuwasha ya kiwiko cha joto cha tanuru ya umeme

Hapana. Halijoto ya kuzima

/r Kushikilia muda /min Mbinu ya kupoeza Kiwango cha joto% Kushikilia muda /min Mbinu ya kupoeza

2 1000 bado hewa

3 1000 kulazimishwa kupoeza hewa

4 1000 30 kupoza mafuta 500 60 kupoeza hewa

5 900 kupoza maji

6 950 kupoza maji

7 1000 kupoza maji

Kwa muhtasari, kutoka kwa uhusiano kati ya ukubwa wa nafaka austenite, ushupavu wa athari ya joto la chini, elongation, nguvu ya mavuno, nguvu ya mvutano na mali nyingine na hali ya joto ya quenching, hali ya baridi, joto linalofaa la kuzimisha linapaswa kuwa 900 ~ 1000 ua, kunyunyizia maji baridi. baada ya kuzima. Kwa sasa, hali ya joto ya kuzima inapokanzwa inayotumiwa chini ya hali ya uzalishaji ni 950 ~ 1050 ° C, na njia ya baridi ni dawa ya maji au baridi ya hewa.