- 28

- Jan

Ukukhethwa kwendlela yokupholisa kunye ne-induction enamandla yokufudumeza i-elbow quenching process parameters

Ukukhethwa kwendlela yokupholisa kunye ne-induction enamandla yokufudumeza i-elbow quenching process parameters

Iiparamitha zenkqubo yokufudumeza kunye nokucima ubukhulu becala zibhekiselele kwiqondo lobushushu le-austenitizing kunye nendlela yokupholisa yokucima. Phakathi kwazo, ukhetho lobushushu obuqinileyo lusekwe ikakhulu ekufumaneni ubungakanani obuziinkozo obulungileyo, ukuqina kobushushu obuphantsi, kunye nokomelela kwesivuno esiphakamileyo kunye nokomelela kokuqina. Ezi mpawu nazo kufuneka zidityaniswe nenkqubo yokuthambisa ukumisela. Iibhobho zokugoba zamabanga ahlukeneyo amandla zineemfuno ezahlukeneyo zomsebenzi okhankanywe ngasentla. Thatha ingqiniba ye-X80 njengomzekelo ukubonisa indlela yokumisela iiparamitha zenkqubo yokucima. Ukubunjwa kweekhemikhali zovavanyo lombhobho wensimbi kunye nentsimbi ye-elbow zidweliswe kwiThebhile 10-1.

Itheyibhile 10-1 Ukubunjwa kweekhemikhali zemibhobho yentsimbi kunye neengqiniba zokuvavanya

Isampulu yokwakheka kweekhemikhali (iqhezu lobunzima)/%

C Si Mn PS Cr Mo Ni Nb V Ti Cu B Al

Umbhobho wentsimbi A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 – 0.03

B 0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

Umzimba wombhobho wengqiniba 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. 0001 0. 03

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. 0001 0. 02

Okokuqala, sebenzisa imibhobho yentsimbi A kunye no-B, usebenzisa indlela yokufudumala yesithando sombane kwilabhoratri ukugqiba oku kulandelayo kumxholo wovavanyo olufanelekileyo.

(1) Ubudlelwane phakathi kokucima ukushisa kunye nobukhulu bengqolowa ye-austenite Ubudlelwane phakathi kobushushu bokufudumala kunye nobukhulu beenkozo buboniswa kuMfanekiso 10-2. Phantsi kweemeko zovavanyo, i-austenitize kwi-1000°C. Emva kokucinywa kwamanzi kunye nokufudumala kwi-500 ° C kwi-1h, ubungakanani bengqolowa obubangelwa bulandelayo. Ngaphantsi kweemeko zokuvelisa, i-elbow eshushu ipholile ngamanzi kwaye iphantsi kwe-500 ° C , Ubungakanani bengqolowa emva kokugcinwa kobushushu kwi-1h yi-13km. Phantsi kweemeko zovavanyo kunye neemeko zemveliso, ubungakanani obufunyenweyo be-austenite busondele kakhulu. Ukususela kwimbono yokucima ukushisa okutshisa kunye nobukhulu beenkozo zengqiniba emva konyango lokugqibela, kufuneka kube nokwenzeka ukukhetha umda ophezulu wokushisa ukucima ukuba ube malunga ne-1000 ° C. Ubukhulu bobukhulu beenkozo bunempembelelo enkulu kumandla wesivuno kunye nokuqina kobushushu obuphantsi bengqiniba. Phantsi kweemeko eziqhelekileyo, ubukhulu bengqolowa bucolile

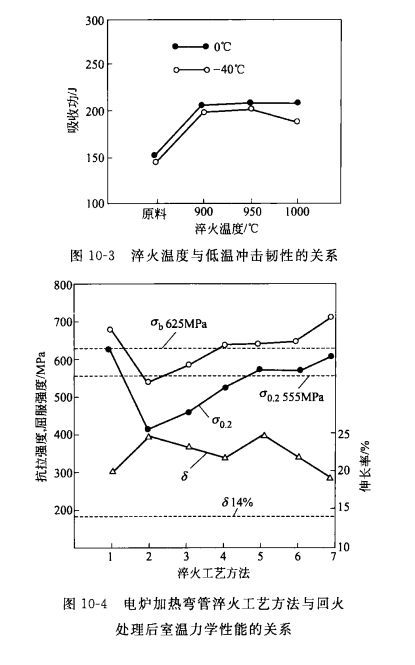

Incinci, iphezulu amandla emveliso yengqiniba, ingcono ukuqina kobushushu obuphantsi. (2) Ubudlelwane phakathi kokucima ubushushu kunye nobushushu obuphantsi bempembelelo yokuqina Umfanekiso we-10-3 ubonisa ubudlelwane phakathi kobushushu bokucima kunye nobushushu obuphantsi bempembelelo yokuqina kwi-0 ° C kunye ne -40 ° C. Kwi-0 ° C, ukuqina kwempembelelo ye-900~1000 ° C ayitshintshi kakhulu; kwiqondo lokushisa lama-40 ° C, xa ubushushu bokucima bungaphezulu kwe-950 ° C, ukuqina kwempembelelo kudla ukuhla. Ukusuka kule meko ingasentla, ubushushu bokucima kwengqiniba akufanele budlule kwi-950℃ kangangoko kunokwenzeka.

Ubudlelwane phakathi kwenkqubo yokucima kunye neempawu zoomatshini Inkqubo yokucima ibandakanya ukucima ubushushu, izinga lokupholisa (isithuba sokupholisa). Umphumo kumandla kunye nokwandiswa kwentsimbi kuboniswe kuMfanekiso 10-4. Imixholo yeenkqubo ezisixhenxe zokucima kuMfanekiso 10-4 zidweliswe kwiThebhile 10-2. Iigophe ezintathu kwi-Figure 10-4 ngokulandelelana zimele ubuncinci beemfuno ze-δb, δ0.2, kunye ne-δ ye-X80 yemigangatho yemibhobho yentsimbi kwinqanaba le-APIspec 5L. Ukususela kwidatha kwi-Figure 10-4, kunokubonwa ukuba amandla amanzi acinyiweyo kunye neesampuli ezipholileyo, kubandakanywa nobude (jonga uMzobo 10-4), uhlangabezana neemfuno zomgangatho; ngelixa i-air-cooled and oil-cooled and tempered samples Amandla alo angaphantsi kwemfuneko eqhelekileyo. Kuyabonakala ukuba, ngokwembono yobushushu bokucima, inkqubo yokucima amanzi epholileyo i-900-1000℃ ihambelana nenqanaba le-X80 lokugoba unyango lobushushu bentsimbi. Itheyibhile 10-2 Ukucinywa kunye nenkqubo yonyango yokufudumeza i-elbow yesithando somlilo sombane

Hayi Ukucima ubushushu

/r Ukubamba ixesha / umz Indlela yokupholisa Ubushushu bobushushu% Ukubamba ixesha / min Indlela yokupholisa

Ngama-2 1000 asemoyeni

3 1000 ukupholisa umoya ngenkani

4 1000 30 ukupholisa ioli 500 60 ukupholisa umoya

Ama-5 900 okupholisa amanzi

Ama-6 950 okupholisa amanzi

Ama-7 1000 okupholisa amanzi

Isishwankathelo, ukusuka kubudlelwane phakathi kobungakanani bengqolowa ye-austenite, ubushushu obuphantsi befuthe lokuqina, ukunwebeka, amandla esivuno, amandla okuqina kunye nezinye iipropathi kunye nobushushu bokucima, iimeko zokupholisa, ubushushu obufanelekileyo bokucima kufuneka bube ngamacingo angama-900 ~ 1000, ukupholisa amanzi okutshiza. emva kokuphumla. Okwangoku, i-induction yokucima ukushisa kweqondo lokushisa elisetyenziswe phantsi kweemeko zemveliso yi-950 ~ 1050 ° C, kwaye indlela yokupholisa i-spray yamanzi okanye ukupholisa umoya obandayo.