- 28

- Jan

Selection of cooling method and strong induction heating elbow quenching process parameters

Selection of cooling method and strong induction heating elbow quenching process parameters

The process parameters of induction heating and quenching mainly refer to the austenitizing temperature and the quenching cooling method. Among them, the selection of austenitizing temperature is mainly based on obtaining fine grain size, good low temperature toughness, and higher yield strength and tensile strength. These properties also need to be combined with the tempering process to determine. Bend pipes of different strength grades have different requirements for the above-mentioned performance. Take the X80 elbow as an example to illustrate the method of determining its quenching process parameters. The chemical composition of the test steel pipe and elbow steel is listed in Table 10-1.

Table 10-1 Chemical composition of steel pipes and elbows for testing

Sample chemical composition (mass fraction)/%

C Si Mn P S Cr Mo Ni Nb V Ti Cu B Al

Steel pipe A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 — 0.03

B 0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

Elbow pipe body 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. 0001 0. 03

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. 0001 0. 02

First of all, use the steel pipes A and B, using the traditional electric furnace heating method in the laboratory to complete the following relevant test contents.

(1) The relationship between quenching temperature and austenite grain size The relationship between heating temperature and grain size is shown in Figure 10-2. Under test conditions, austenitize at 1000°C. After water quenching and tempering at 500°C for 1h, the resulting grain size is as follows. Under production conditions, the hot elbow is water-cooled and subjected to 500°C , The grain size after heat preservation for 1h is 13km. Under the test conditions and production conditions, the obtained austenite grain size is very close. From the perspective of the quenching heating temperature and the grain size of the elbow after the final treatment, it should be feasible to select the upper limit of the quenching temperature to be about 1000°C. The thickness of the grain size has a greater impact on the yield strength and low temperature toughness of the elbow. Under normal conditions, the finer the grain size

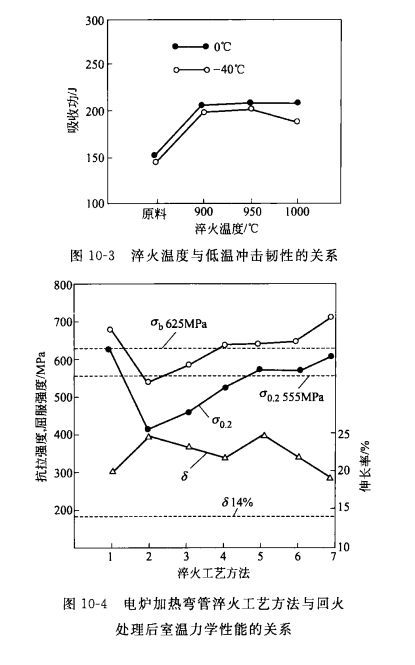

Smaller, the higher the yield strength of the elbow, the better the low-temperature toughness. (2) The relationship between quenching temperature and low-temperature impact toughness Figure 10-3 shows the relationship between quenching temperature and low-temperature impact toughness at 0°C and -40°C. At 0°C, the impact toughness of 900~1000°C does not change much; at a temperature of 40°C, when the quenching temperature is higher than 950°C, the impact toughness tends to decrease. From the above situation, the quenching temperature of the elbow should not exceed 950℃ as much as possible.

The relationship between quenching process and mechanical properties Quenching process includes quenching temperature, cooling rate (cooling medium). The effect on the strength and elongation of steel is shown in Figure 10-4. The contents of the seven quenching processes in Figure 10-4 are listed in Table 10-2. The three curves in Figure 10-4 respectively represent the minimum requirements for δb, δ0.2, and δ of X80 grade steel pipes in the APIspec 5L standard. From the data in Figure 10-4, it can be seen that the strength of the water quenched and tempered samples, including elongation (see Figure 10-4), meets the requirements of the standard; while the air-cooled and oil-cooled and tempered samples Its strength is lower than the standard requirement. It can be seen that, from the perspective of the quenching temperature, the 900-1000℃ water-cooled quenching process is in line with the X80 grade bending steel heat treatment. Table 10-2 Quenching and tempering treatment process of electric furnace heating elbow

No. Quenching temperature

/r Holding time /min Cooling method Tempering temperature% Holding time /min Cooling method

2 1000 still air

3 1000 forced air cooling

4 1000 30 oil cooling 500 60 air cooling

5 900 water cooling

6 950 water cooling

7 1000 water cooling

In summary, from the relationship between the austenite grain size, low-temperature impact toughness, elongation, yield strength, tensile strength and other properties and the quenching temperature, cooling conditions, the appropriate quenching temperature should be 900~ 1000 fences, spray water cooling after quenching. At present, the induction heating quenching temperature used under production conditions is 950~1050°C, and the cooling method is water spray or cold air cooling.