- 28

- Jan

Ukukhethwa kwendlela yokupholisa kanye nemingcele yenqubo yokucisha indololwane yokufaka ukushisa okuqinile

Ukukhethwa kwendlela yokupholisa kanye nemingcele yenqubo yokucisha indololwane yokufaka ukushisa okuqinile

Imingcele yenqubo yokushisisa kokungeniswa kanye nokucisha ikakhulukazi ibhekisela ekushiseni kwe-austenitizing kanye nendlela yokupholisa yokucisha. Phakathi kwazo, ukukhethwa kwezinga lokushisa le-austenitizing kusekelwe ngokuyinhloko ekutholeni usayizi wokusanhlamvu ocolekile, ukuqina okuhle kwezinga lokushisa eliphansi, namandla esivuno esiphezulu namandla aqinile. Lezi zakhiwo nazo zidinga ukuhlanganiswa nenqubo yokushisa ukuze kunqunywe. Amapayipi okugoba amabanga ahlukene amandla anezidingo ezihlukene zomsebenzi oshiwo ngenhla. Thatha indololwane ye-X80 njengesibonelo ukuze ubonise indlela yokunquma imingcele yenqubo yokucisha. Ukwakheka kwamakhemikhali kwepayipi lensimbi lokuhlola kanye nensimbi yendololwane kubhalwe kuThebula 10-1.

Ithebula 10-1 Ukwakheka kwamakhemikhali kwamapayipi ensimbi nezindololwane ukuze kuhlolwe

Ukwakheka kwamakhemikhali okuyisampula (ingxenyana yobuningi)/%

C Si Mn PS Cr Mo Ni Nb V Ti Cu B Al

Ipayipi lensimbi A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 — 0.03

B 0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

Umzimba wepayipi indololwane 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. 0001 0. 03

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. 0001 0. 02

Okokuqala, sebenzisa amapayipi ensimbi A no-B, usebenzisa indlela evamile yokushisa isithando somlilo kagesi elabhorethri ukuze ugcwalise okuqukethwe kokuhlola okulandelayo okufanelekile.

(1) Ubudlelwano phakathi kwezinga lokushisa lokucisha kanye nosayizi wokusanhlamvu we-austenite Ubudlelwano phakathi kwezinga lokushisa lokushisa nosayizi wokusanhlamvu buboniswa kuMfanekiso 10-2. Ngaphansi kwezimo zokuhlola, i-austenitize ku-1000°C. Ngemuva kokucinywa kwamanzi kanye nokufudumeza ku-500 ° C nge-1h, usayizi wokusanhlamvu ophumayo umi kanje. Ngaphansi kwezimo zokukhiqiza, indololwane eshisayo ipholile ngamanzi futhi ingaphansi kuka-500 ° C , Usayizi wokusanhlamvu ngemva kokugcinwa kokushisa kwe-1h ngu-13km. Ngaphansi kwezimo zokuhlola nezimo zokukhiqiza, usayizi wokusanhlamvu we-austenite otholiwe useduze kakhulu. Ngokombono wezinga lokushisa elicishayo lokushisisa kanye nosayizi wokusanhlamvu wendololwane ngemva kokwelashwa kokugcina, kufanele kube nokwenzeka ukukhetha umkhawulo ongaphezulu wokushisa wokucisha ukuba ube ngu-1000°C. Ubukhulu bosayizi wokusanhlamvu bunomthelela omkhulu emandleni esivuno kanye nokuqina kokushisa okuphansi kwendololwane. Ngaphansi kwezimo ezijwayelekile, usayizi wokusanhlamvu ungcono kakhulu

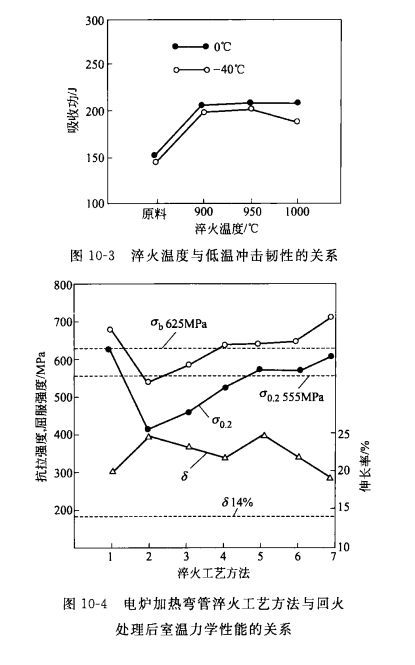

Okuncane, ukuphakama kwamandla endololwane, kuba ngcono ukuqina kwezinga lokushisa eliphansi. (2) Ubudlelwano phakathi kwezinga lokushisa elicishayo kanye nokuqina komthelela wezinga lokushisa eliphansi Umfanekiso 10-3 ubonisa ubudlelwano phakathi kwezinga lokushisa lokucisha kanye nokuqina komthelela wezinga lokushisa eliphansi ku-0°C no-40°C. Ku-0°C, ukuqina komthelela okungu-900~1000°C akushintshi kakhulu; ezingeni lokushisa elingu-40°C, lapho izinga lokushisa lokucisha lingaphezu kuka-950°C, ukuqina komthelela kuthanda ukwehla. Kusukela kulesi simo esingenhla, izinga lokushisa lokucisha indololwane akufanele lidlule ku-950℃ ngangokunokwenzeka.

Ubudlelwano phakathi kwenqubo yokucisha kanye nezakhiwo zemishini Inqubo yokucisha ihlanganisa izinga lokushisa lokucisha, izinga lokupholisa (indawo yokupholisa). Umphumela wamandla nokwelulwa kwensimbi uboniswa kuMfanekiso 10-4. Okuqukethwe kwezinqubo eziyisikhombisa zokucisha kuMfanekiso 10-4 zibalwe kuThebula 10-2. Amajika amathathu kuMfanekiso 10-4 ngokulandelanayo amele izimfuneko ezincane ze-δb, δ0.2, kanye no-δ yamapayipi ensimbi ebanga le-X80 kuzinga le-APIspec 5L. Kusukela kudatha eku-Figure 10-4, kungabonakala ukuthi amandla amanzi acishiwe kanye namasampula athambile, okuhlanganisa ubude (bona Umfanekiso 10-4), ahlangabezana nezidingo zezinga; kuyilapho amasampula apholile komoya kanye nanamafutha apholile futhi athambile Amandla ayo aphansi kunesidingo esijwayelekile. Kuyabonakala ukuthi, ngokombono wezinga lokushisa lokucisha, inqubo yokucisha amanzi epholile engu-900-1000℃ ihambisana nokwelashwa kokushisa kwensimbi egobayo yezinga le-X80. Ithebula 10-2 Inqubo yokwelapha yokucisha kanye neyokushisa yesithando somlilo sikagesi indololwane

Cha. Icisha izinga lokushisa

/r Ukubamba isikhathi/min Indlela yokupholisa Izinga lokushisa lokushisa% Ukubamba isikhathi/min Indlela yokupholisa

2 1000 esekhona emoyeni

3 1000 ukupholisa umoya ngempoqo

4 1000 30 ukupholisa amafutha 500 60 ukupholisa umoya

5 900 ukupholisa amanzi

6 950 ukupholisa amanzi

7 1000 ukupholisa amanzi

Kafushane, kusukela ebudlelwaneni obuphakathi kosayizi wokusanhlamvu we-austenite, izinga lokushisa eliphansi lomthelela wokuqina, ukuphakama, amandla esivuno, amandla aqinile nezinye izakhiwo kanye nezinga lokushisa lokucisha, izimo zokupholisa, izinga lokushisa elifanele lokucisha kufanele libe uthango lwama-900 ~ 1000, ukupholisa amanzi ngokufafaza. ngemva kokupheka. Njengamanje, izinga lokushisa lokucisha ukushisa lokungeniswa elisetshenziswa ngaphansi kwezimo zokukhiqiza lingu-950~1050°C, futhi indlela yokupholisa isifutho samanzi noma ukupholisa komoya obandayo.