- 21

- Sep

Imishini yokushisa ye-motor rotor kanye nejakhethi yokushisa shaft

I-rotor yemoto imishini yokushisa yokufakelwa kanye nejacket yokushisa shaft

I-rotor ye-shaftless ye-motor yenziwe ngamashidi ensimbi ye-silicon futhi ithululelwa yonke nge-aluminium liquid. Ngemva kokushiselwa ezingeni elithile lokushisa, ifakwa imikhono yokushisa ku-shaft ecutshunguliwe. Ngemuva kokupholisa, i-rotor engenalutho ihlanganiswe kanye ne-shaft ukuze ibe igundane. I-rotor yekheji.

Esikhathini esedlule, izitshalo eziningi ezikhiqizayo zazisebenzisa iziko lomlilo noma iziko lokumelana ukushisa ama-rotor angenawo ama-shaftless. Ukuze kuthuthukiswe izinga lokushisa kanye nokukhiqiza, futhi kuncishiswe ukusetshenziswa kwamandla kanye nezindleko zokukhiqiza, imishini yokushisa yokungeniswa kwama-rotor angenawo ama-shaftless yathuthukiswa futhi yathola imiphumela engcono. Imiphumela emihle, manje esetshenziswa ekukhiqizeni

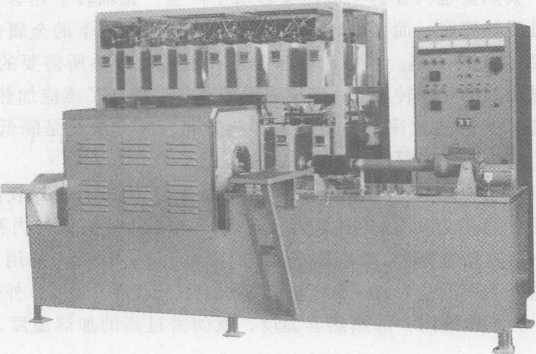

Imvamisa yamanje ikhethiwe ngokusho kobubanzi be-rotor shaftless. Ku-rotor engena-shaftless yemoto evamile, imishini yokushisa yokufaka imvamisa yamandla isetshenziselwa ububanzi bayo obukhulu; kuma-rotor amancane we-motor shaftless, kusetshenziswa imishini yokushisa yokungenisa imvamisa emaphakathi. Umfanekiso 12-24 ubonisa isethi ephelele yemishini yokushisa yokungenisa imvamisa ye-rotor yamandla e-shaftless, okuhlanganisa imishini yokushisa yokungenisa imvamisa yamandla, amakhabethe kagesi, namakhabethe kagesi.

Umfanekiso 12-24 umshini wokushisa we-rotor ongenawo shaftless

1. Amapharamitha wokucubungula we-shaftless rotor hot sleeve shaft

Inqubo ye-shaftless rotor hot sleeve shaft isekelwe ngokuyinhloko ekuphazamiseni okuphezulu phakathi kwe-shaft kanye nembobo yangaphakathi ye-rotor engenalutho ukuze kunqunywe izinga lokushisa lokushisa kwe-rotor shaftless. Izinga lokushisa eliphansi lokushisisa (ngaphandle) yilapho i-H——shaft kanye Nokuphazamiseka okukhulu phakathi kobubanzi obungaphakathi be-rotor engena-shaftless (mm); D——ububanzi obungaphakathi be-rotor engena-shaftless (mm); K——i-coefficient yomugqa yokwandisa yeshidi lensimbi ye-silicon. K= (11 ~13) 10-6

Ukuze wenze lula umkhono wokushisa we-rotor engena-shaft ku-shaft, futhi ucabangele ukwehla kwezinga lokushisa ngesikhathi senqubo yomkhono wokushisa, izinga lokushisa lokushisa le-rotor engenalutho kufanele libe ngamadigri amaningi ngaphezu kwezinga lokushisa lokushisa elincane, kuye ngokuthi isimo esiqondile.

2. Ukukhethwa kwemvamisa yamanje yemishini yokushisa yokungeniswa

Ukusebenza kahle kwemishini yokushisa yokungeniswa kwe-workpiece kunqunywa ngokuyisisekelo ukukhetha okulungile kwemvamisa yamanje. Ukujula kokungena kwe-p yamanje-i-resistivity yesiqeshana somsebenzi (ft • cm); f-ukufinyeleleka okulinganiselwe kwesiqephu somsebenzi;

Kungabonakala kufomula engenhla ukuthi lapho i-resistivity p kanye nokufinyeleleka okuhlobene kwe-workpiece kuhlala njalo, njengoba i-frequency yamanje ikhula, ukujula kokungena kwamanje ku-workpiece kuba kuncane futhi kuncane. Ngokuvamile kukholakala ukuthi i-current induced igeleza kuphela kungqimba lwamanje olungena, futhi ukushisa kwalo kukhiqizwa kuphela kulolu ungqimba olungena lwamanje. I-shaftless rotor eshisayo yomkhono we-shaft idinga imbobo yangaphakathi ye-rotor engenalutho ukuze inwetshwe ngokushisa, futhi insimbi engaphansi kokungena kwamanje kokujula ku-rotor engena-shaftless ingashiswa kuphela kusuka kungqimba olushisayo ngendlela ye-thermal conductive. Uma imvamisa yamanje iphakeme, isikhathi esidingekayo sokudlulisa ukushisa okunjalo siba side, okwandisa ukushisa okuchithwa endaweni ezungezile nge-rotor eshisayo engena-shaftless, futhi kunciphisa ukusebenza kahle okushisayo kwedivayisi yokushisisa yokungeniswa. Ukuze kuthuthukiswe ukusebenza kahle kokushisa kwemishini yokushisa yokungeniswa, isikhathi sokushisa kufanele sifinyezwe. Indlela yokunciphisa imvamisa yamanje futhi ukwandise ukujula kokungena kwamanje kucwecwe lokusebenza.

Njengoba i-silicon steel sheet ye-shaftless rotor inokufinyeleleka okuhle kazibuthe, ukufinyeleleka kwayo okuhlobene kuphezulu, futhi ukujula kokungena kwayo kwamanje kuncane. Lapho i-rotor ye-shaftless ishiswa nge-1000Hz yamanje, umehluko wokushisa phakathi kwendawo yangaphandle kanye nembobo yangaphakathi ngu-100 -150 ^, okungukuthi, lapho imbobo yangaphakathi ingu-250Y, izinga lokushisa elingaphandle liyi-350-400 nil. Isibonelo, uma kusetshenziswa ukushisisa kwamanje kokungeniswa kwemvamisa yamandla, umehluko wezinga lokushisa phakathi kwezindawo zangaphakathi nezingaphandle ungama-20~50 ubude. Uma izinga lokushisa elingaphakathi lembobo lingu-250Y futhi izinga lokushisa langaphandle lingu-270~300^o, izinga lokushisa lokushisa liphezulu kakhulu ukuze kuzuzwe izinga lokushisa elifanayo lejazi lokufudumeza. Ivumela ukonga amandla.