- 06

- Dec

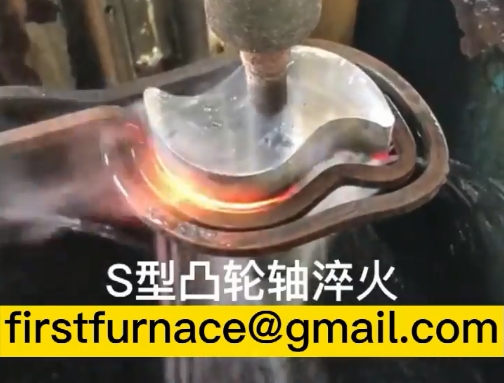

Yadda za a carburize da zafi bi da camshafts?

Yadda za a carburize da zafi bi da camshafts?

1. Kai tsaye quenching bayan carburizing yana da abũbuwan amfãni daga high samar yadda ya dace, low cost, da kuma oxidative decarburization. Duk da haka, saboda yawan zafin jiki na carburizing, hatsi na austenite suna girma, martensite yana da girma bayan quenching, da kuma austenite da aka riƙe Har ila yau, akwai ƙarin jiki, don haka saka juriya da taurin ba su da kyau. Ya dace kawai don ƙarfe mai ƙaƙƙarfan ƙaƙƙarfan ƙira da sassa tare da ƙananan buƙatun juriya ko ƙananan sassa masu ɗaukar nauyi.

2. quenching na lokaci ɗaya shine bayan an kwantar da carburizing a hankali, sannan a sake yin zafi zuwa zazzabi sama da zafin jiki mai mahimmanci sannan a kashe. Idan aka kwatanta da quenching kai tsaye, quenching na lokaci ɗaya na iya daidaita tsarin ƙarfe zuwa wani ɗan lokaci. Lokacin da buƙatun tushen tsarin ya yi girma, zafin zafin wuta na quenching ya ɗan yi girma fiye da Ac3. Don ɓangarorin da ba su da nauyi sosai amma suna da juriya mafi girma da buƙatun aiki mai ƙarfi a saman. The quenching zafin jiki ya zama 30 ℃~50 ℃ sama da Ac1, sabõda haka, surface Layer hatsi za a mai ladabi, amma core tsarin ba za a ƙwarai inganta, da kuma yi zai zama dan kadan muni.

3. quenching na biyu Don ƙarfe mai manyan kayan aikin injiniya ko ainihin ƙarfe mai ƙima, yakamata a yi amfani da quenching na biyu. Manufar quenching na farko shine don inganta tsarin tushen, kuma zafin jiki na dumama shine 30 ℃ ~ 50 ℃ sama da Ac3. Manufar quenching na biyu shine don tsaftace tsarin Layer na saman don samun kyakkyawan martensite da siminti na sakandare da aka rarraba daidai. Zafin dumama shine 30 ℃ ~ 50 ℃ sama da Ac1.

https://songdaokeji.cn/14033.html

https://songdaokeji.cn/14035.html

https://songdaokeji.cn/14037.html