- 11

- Apr

Zaɓin hanyar sanyaya da ƙaƙƙarfan induction dumama ma’aunin aikin kashe gwiwar gwiwar hannu

Zaɓin hanyar sanyaya da ƙaƙƙarfan induction dumama ma’aunin aikin kashe gwiwar gwiwar hannu

Siffofin aiwatar da dumama shigar da quenching galibi suna nuni ne ga austenitizing zafin jiki da hanyar quenching sanyaya. Daga cikin su, zaɓin austenitizing zafin jiki ya dogara ne akan samun girman hatsi mai kyau, ƙarancin zafin jiki mai kyau, da ƙarfin yawan amfanin ƙasa da ƙarfin ɗaure. Waɗannan kaddarorin kuma suna buƙatar haɗa su tare da tsarin zafin jiki don tantancewa. Lanƙwasa bututu na nau’ikan ƙarfi daban-daban suna da buƙatu daban-daban don aikin da aka ambata a sama. Ɗauki gwiwar gwiwar X80 a matsayin misali don kwatanta hanyar tantance sigogin tsarin sa. Abubuwan sinadaran gwajin bututun karfe da karfen gwiwar hannu an jera su a cikin Tebu 10-1.

Tebur 10-1 Abubuwan sinadaran na bututun ƙarfe da gwiwar hannu don gwaji

Samfurin ƙunshin sinadarai (ƙasasshen taro)/%

C Si Mn PS Cr Mo Ni Nb V Ti Cu B Al

Bututun Karfe A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 – 0.03

0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

Jikin gwiwar hannu 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. Bayani na 0001

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. Farashin 0001

Da farko, yi amfani da bututun ƙarfe A da B, ta yin amfani da hanyar dumama tanderun lantarki na gargajiya a cikin dakin gwaje-gwaje don kammala abubuwan gwajin da suka dace.

(1) Dangantakar da ke tsakanin zafin zafin jiki da girman hatsi na austenite Alakar da ke tsakanin dumama zafin jiki da girman hatsi an nuna a cikin Hoto 10-2. Karkashin yanayin gwaji, austenitize a 1000°C. Bayan da aka kashe ruwa da zafi a 500 ° C don 1h, sakamakon girman hatsi kamar haka. A karkashin yanayin samarwa, gwiwar hannu mai zafi yana sanyaya ruwa kuma an sanya shi zuwa 500 ° C, Girman hatsi bayan adana zafi don 1h shine 13km. A ƙarƙashin yanayin gwaji da yanayin samarwa, girman hatsin da aka samu austenite yana kusa sosai. Daga hangen yanayin zafin zafi mai kashewa da girman hatsin gwiwar hannu bayan jiyya ta ƙarshe, ya kamata a yi yuwuwar zaɓi mafi girman iyakar zafin jiki don zama kusan 1000 ° C. Girman girman hatsi yana da tasiri mafi girma akan ƙarfin yawan amfanin ƙasa da ƙananan zafin jiki na gwiwar hannu. A ƙarƙashin yanayin al’ada, mafi kyawun girman hatsi

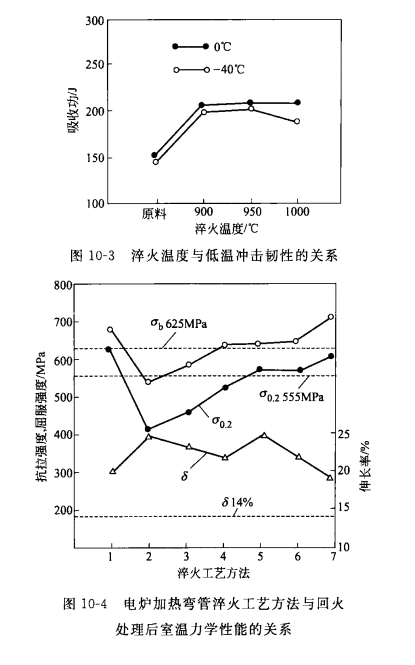

Karami, mafi girman ƙarfin yawan amfanin ƙasa na gwiwar hannu, mafi kyawun ƙarancin zafin jiki. (2) Dangantakar da ke tsakanin zafin jiki mai kashewa da ƙarancin zafin jiki mai ƙarfi Hoto na 10-3 yana nuna alaƙar da ke tsakanin zafin jiki mai kashewa da ƙarancin zafi mai ƙarfi a 0 ° C da -40 ° C. A 0 ° C, tasirin taurin 900 ~ 1000 ° C baya canzawa da yawa; a zafin jiki na 40 ° C, lokacin da zafin jiki ya kai sama da 950 ° C, tasirin tasirin yana ƙoƙarin raguwa. Daga sama halin da ake ciki, da quenching zafin jiki na gwiwar hannu kada ya wuce 950 ℃ kamar yadda zai yiwu.

Dangantaka tsakanin quenching tsari da inji Properties Quenching Tsarin ya hada da quenching zazzabi, sanyaya kudi (sanyi matsakaici). Ana nuna tasirin ƙarfin da haɓakar ƙarfe a cikin hoto 10-4. Abubuwan da ke cikin matakai bakwai na kashewa a cikin hoto na 10-4 an jera su a cikin Tebur 10-2. Hanyoyi uku a cikin Hoto 10-4 bi da bi suna wakiltar mafi ƙarancin buƙatun δb, δ0.2, da δ na bututun ƙarfe na darajar X80 a cikin ma’aunin APIspec 5L. Daga bayanan da ke cikin Hoto 10-4, ana iya ganin cewa ƙarfin ruwan da aka kashe da samfurori masu zafi, ciki har da elongation (duba Hoto 10-4), ya sadu da bukatun ma’auni; yayin da aka sanyaya iska da man da aka sanyaya da kuma samfurori masu zafi Ƙarfinsa ya fi ƙasa da abin da ake bukata. Ana iya ganin cewa, daga hangen nesa na quenching zafin jiki, da 900-1000 ℃ ruwa sanyaya quenching tsari ne a cikin layi tare da X80 sa lankwasawa karfe zafi magani. Table 10-2 Quenching da tempering jiyya tsari na lantarki tanderun dumama gwiwar hannu

A’a. Ƙunƙarar zafin jiki

/ r Lokacin Riƙe /min Hanyar sanyaya zafin jiki % Riƙe Lokacin /min Hanyar sanyaya

2 1000 har yanzu iska

3 1000 tilasta sanyaya iska

4 1000 30 sanyaya mai 500 60 sanyaya iska

5 900 sanyaya ruwa

6 950 sanyaya ruwa

7 1000 sanyaya ruwa

A taƙaice, daga alaƙar da ke tsakanin girman hatsi austenite, ƙarancin zafin jiki mai ƙarfi mai ƙarfi, elongation, ƙarfin yawan amfanin ƙasa, ƙarfin ƙarfi da sauran kaddarorin da zafin jiki na quenching, yanayin sanyaya, zafin zafin da ya dace ya zama shinge 900 ~ 1000, fesa ruwa sanyaya. bayan quenching. A halin yanzu, induction dumama quenching zafin jiki da ake amfani da shi a ƙarƙashin yanayin samarwa shine 950 ~ 1050 ° C, kuma hanyar sanyaya shine feshin ruwa ko sanyaya iska.