- 11

- Apr

Khetho ea mokhoa oa ho pholisa le mekhoa e matla ea ho futhumatsa setsoe ea ho tima

Khetho ea mokhoa oa ho pholisa le mekhoa e matla ea ho futhumatsa setsoe ea ho tima

Mehato ea ts’ebetso ea ho futhumala ha induction le ho tima haholo e bua ka mocheso oa austenitizing le mokhoa oa ho futhumatsa oa ho tima. Har’a tsona, khetho ea mocheso oa austenitizing e ipapisitse le ho fumana boholo bo botle ba lijo-thollo, boima bo botle ba mocheso o tlase, le matla a chai a phahameng le matla a thata. Lintho tsena li boetse li hloka ho kopanngoa le mokhoa oa ho futhumatsa ho tseba. Liphaephe tse kobehang tsa limaraka tse fapaneng tsa matla li na le litlhoko tse fapaneng bakeng sa ts’ebetso e boletsoeng ka holimo. Nka setsoe sa X80 e le mohlala ho bontša mokhoa oa ho khetholla mekhahlelo ea ts’ebetso ea ho tima. Sebopeho sa lik’hemik’hale tsa phala ea tšepe ea teko le tšepe ea setsoe li thathamisitsoe ho Lethathamo la 10-1.

Letlapa la 10-1 Sebopeho sa lik’hemik’hale tsa liphaephe tsa tšepe le li-elbows bakeng sa tlhahlobo

Mohlala oa sebopeho sa lik’hemik’hale (karolo ea bongata)/%

C Si Mn PS Cr Mo Nb V Ti Cu B Al

Peipi ea tšepe A 0. 06 0. 18 1. 78 0. 016 0. 004 0. 18 0. 26 0. 02 0. 06 0.02 0.01 0.01 – 0.03

B 0.05 0.21 1.74 0.018 0. 002 0. 15 0. 18 0.01 0. 07 0. 02 0.01 0.01 0. 001 0. 04

‘Mele oa phala ea setsoe 0. 08 0. 17 1. 68 0.010 0. 002 0.09 0. 20 0. 20 0. 05 0. 03 0. 02 0. 15 <0. 0001 0. 03

Weld 0.06 0. 27 1.65 0.012 0. 003 0. 01 0. 26 0. 11 0. 03 0. 02 0. 02 0. 10 <0. 0001 0. 02

Pele ho tsohle, sebelisa liphaephe tsa tšepe A le B, u sebelisa mokhoa o tloaelehileng oa ho futhumatsa sebōpi sa motlakase ka laboratoring ho phethela litaba tse latelang tsa tlhahlobo.

(1) Kamano pakeng tsa mocheso oa ho tima le boholo ba lijo-thollo tsa austenite Kamano pakeng tsa mocheso oa mocheso le boholo ba lijo-thollo e bontšoa ho Setšoantšo sa 10-2. Tlas’a maemo a teko, austenitize ho 1000°C. Ka mor’a ho tima metsi le ho futhumatsa ka 500 ° C bakeng sa 1h, boholo ba lijo-thollo bo hlahang ka tsela e latelang. Tlas’a maemo a tlhahiso, setsoe se chesang se pholile ka metsi ‘me se tlas’a 500 ° C , Boholo ba lijo-thollo ka mor’a ho boloka mocheso bakeng sa 1h ke 13km. Tlas’a maemo a teko le maemo a tlhahiso, boholo ba lijo-thollo tsa austenite bo haufi haholo. Ho ea ka pono ea mocheso o timang mocheso le boholo ba lijo-thollo tsa setsoe ka mor’a phekolo ea ho qetela, ho lokela ho khoneha ho khetha moeli o ka holimo oa mocheso oa ho tima hore o ka ba 1000 ° C. Botenya ba boholo ba lijo-thollo bo na le tšusumetso e kholo ho matla a lihlahisoa le ho tiea ha mocheso o tlase oa setsoe. Tlas’a maemo a tloaelehileng, boholo ba lijo-thollo bo betere

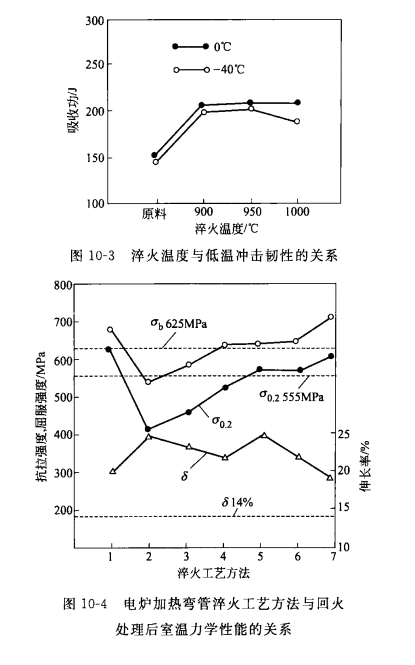

E nyane, ha matla a tlhahiso a holimo a setsoe, a betere ho tiea ha mocheso o tlase. (2) Kamano pakeng tsa mocheso o timang le mocheso o tlase oa ts’usumetso Setšoantšo sa 10-3 se bonts’a kamano pakeng tsa mocheso o timang le mocheso o tlase oa tšusumetso e matla ho 0 ° C le -40 ° C. Ka 0°C, matla a tšusumetso ea 900~1000°C ha a fetohe haholo; ka mocheso oa 40 ° C, ha mocheso oa ho tima o phahame ho feta 950 ° C, boima ba tšusumetso bo atisa ho fokotseha. Ho tloha boemong bo ka holimo, mocheso o timang oa setsoe ha oa lokela ho feta 950 ℃ ka hohle kamoo ho ka khonehang.

Kamano lipakeng tsa ts’ebetso ea ho tima le thepa ea mochini Ts’ebetso ea ho tima e kenyelletsa mocheso oa ho tima, sekhahla sa ho pholisa (mocheso o pholileng). Phello ea matla le bolelele ba tšepe e bontšoa ho Setšoantšo sa 10-4. Likahare tsa lits’ebetso tse supileng tsa ho tima tse hlahang setšoantšong sa 10-4 li thathamisitsoe ho Lethathamo la 10-2. Li-curve tse tharo ho Sets’oants’o sa 10-4 ka ho tatellano li emela litlhoko tse tlase tsa δb, δ0.2, le δ ea lipeipi tsa tšepe tsa sehlopha sa X80 ho maemo a APIspec 5L. Ho tsoa ho data ho Setšoantšo sa 10-4, ho ka bonoa hore matla a metsi a tingoeng le lisampole tse halefileng, ho kenyelletsa le elongation (bona Setšoantšo sa 10-4), se finyella litlhoko tsa maemo; ha lisampole tse pholileng tsa moea le tse pholileng ka oli le tse halefileng Matla a eona a tlase ho feta tlhokahalo e tloaelehileng. Ho ka bonoa hore, ho ea ka pono ea mocheso oa ho tima, mokhoa oa ho tima metsi o pholileng ka metsi a 900-1000 ℃ o lumellana le phekolo ea mocheso oa tšepe ea ho kobeha ea X80. Letlapa la 10-2 Ts’ebetso ea ho tima le ho futhumatsa setsoe sa ho futhumatsa sebopi sa motlakase

Che. Mocheso oa ho tima

/r Ho ts’oara nako /min Mokhoa oa ho pholisa Mocheso oa mocheso% Ho tšoara nako /min Mokhoa oa ho pholisa

2 1000 e ntse e le moeeng

3 1000 e qobelloang ho pholisa moea

4 1000 30 pholiso ea oli 500 60 moea o pholileng

5 900 ho pholisa metsi

6 950 ho pholisa metsi

7 1000 ho pholisa metsi

Ka kakaretso, ho tloha kamano pakeng tsa boholo ba lijo-thollo tsa austenite, matla a matla a mocheso o tlase, ho lelefatsa, matla a chai, matla a tsitsitseng le thepa e ‘ngoe le mocheso oa ho tima, maemo a pholileng, mocheso o nepahetseng oa ho tima e lokela ho ba 900 ~ 1000 terata, ho fafatsa metsi a pholileng. ka mora ho tima. Hajoale, mocheso oa ho tima mocheso oa induction o sebelisoang tlas’a maemo a tlhahiso ke 950 ~ 1050 ° C, ‘me mokhoa oa ho pholisa ke ho fafatsa metsi kapa moea o batang oa moea.