- 27

- Jul

Habka dhalaalidda birta iyo birta qashinka ee foornada dhalaalaysiinta

- 28

- July

- 27

- July

Habka dhalaalidda birta iyo birta qashinka ee foornada dhalaalaysiinta

Before the induction furnace is charged, the residue in the furnace should be removed, and the damage of the furnace lining should be checked. The severely damaged parts have become black due to rapid cooling and should be repaired. The grain size of the repairing material should be slightly smaller than that of the knotted material, and the binder used should be slightly more. Large-scale furnaces that are severely damaged can be hoisted into the furnace iron mold to fill in knots.

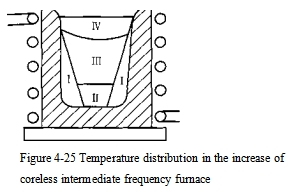

Maadaama heerkulka foornada induction uu si dhakhso ah u dhaco ka dib marka la garaaco, waa in si degdeg ah loo dallaco oo waa in lagu buuxiyaa foosto intii suurtagal ah. Si loo dedejiyo dhalaalka, walxaha waa in loo qaybiyaa si macquul ah iyadoo loo eegayo qaybinta heerkulka foornada. Qaybinta heerkulka foornada induction waxaa lagu muujiyey sawirka 4-25. Sababtoo ah saamaynta maqaarka ee hadda jira, dusha sare ee ku wareegsan ee tiirka walxaha (aagga I) ee u dhow darbiga volute waa aag heerkul sare ah.

Qeybta hoose iyo dhexe (I, TT zone) waxay leeyihiin kuleyl aad u liidata, taas oo ah aag heerkul sare ah, iyo qaybta sare (IV zone) waxay leedahay qulqulka magnetic yar iyo luminta kulaylka weyn, taas oo ah aag heerkul hooseeya.

Si aad u sameysid dharbaaxo hore, 1% walxaha slag ee miisaanka ayaa lagu dari karaa xagga hoose ee foornada ka hor inta aan la dallacin, lime iyo fluorite ayaa lagu daraa foornada alkaline, iyo cullet galaas ayaa lagu daraa foornada acid.

Bilawga dhalaalka, sababtoo ah inductance iyo capacitance on line si deg deg ah iyo si sax ah uma dhigmi karaan, hadda waa mid aan degganayn, sidaas darteed waxa kaliya oo lagu siin karaa awood hoose muddo gaaban. Marka hadda uu xasilloon yahay, waa in loo beddelaa gudbinta culeyska buuxa. Inta lagu jiro habka dhalaalka, capacitor waa in si joogto ah loo hagaajiyaa si loo ilaaliyo qalabka korantada oo leh awood sare. Ka dib marka kharashka si buuxda loo dhalaaliyo, birta dhalaalaysa ayaa la kululeeyaa ilaa xad, ka dibna awoodda wax gelinta waa la dhimay iyadoo loo eegayo shuruudaha dhalaalidda.

Waqtiga dhalaalidda habboon waa in la xakameeyaa. Haddii wakhtiga dhalaalku aad u gaaban yahay, waxay keeni doontaa dhibaatooyin xagga xulashada tamarta iyo awoodda. Haddii ay aad u dheer tahay, waxay kordhin doontaa luminta kulaylka aan faa’iido doonka ahayn. Maro aan habboonayn ama miridhku xad-dhaaf ah ee alaabta foornada waxay keeni doontaa ifafaale “isku-xidhka”, taas oo ay tahay in wax laga qabto waqtiga. “Bridge” waxay ka hortagtaa walxaha aan dhalaalin ee qaybta sare inay ku dhacaan birta dhalaalaysa, waxay fadhiistaan yuhua, iyo kulaylka hoose ee birta dhalaalaysa waxay si fudud u dhaawaci kartaa xuubka foornada, sidoo kale waxay keeni doontaa in birta dhalaalaysa ay nuugaan qadar badan. ee gaaska.

Sababo la xiriira kicinta korantada, dhexda birta dhalaalaysa ayaa soo burqata, iyo dharbaaxadu waxay inta badan ku qulqulaysaa cidhifka lakabka waxayna ku dheggan tahay gidaarka foornada. Sidaa darteed, dharbaaxada waa in si joogto ah loogu daro iyadoo loo eegayo xaaladaha foornada inta lagu jiro habka dhalaalka.