- 25

- Oct

Methods to improve the effectiveness of gas blowing at the bottom of ladle

Methods to improve the effectiveness of gas blowing at the bottom of ladle

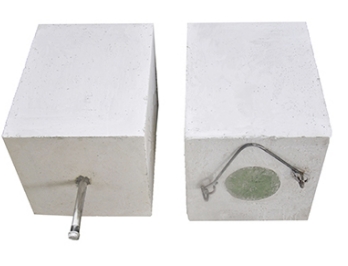

DW series slit type breathable brick

We have analyzed the process of argon blowing at the bottom of the ladle and the requirements for breathable bricks. This article focuses on methods to improve the effectiveness of gas blowing at the bottom of the ladle.

1. Choose better quality breathable bricks

The corrosion resistance and erosion resistance of breathable bricks are inseparable from the effect of the bottom blowing process. It has been learned from practice that after long-term use, traditional slit-type air-permeable bricks will be blocked by slit steel infiltration and slag build-up on air-permeable bricks. At this time, the blow-open rate of the air-permeable brick and the blow-through rate at the bottom of the ladle are naturally difficult to meet the requirements of ladle metallurgy.

Choosing air-permeable bricks with high thermal shock resistance, permeability resistance and erosion resistance is the first step to improve the bottom blowing effect of the ladle.

The slit width, the geometry of the slit, and the wettability of the ventilating core material to molten steel also affect the permeability of the ventilating brick. Therefore, when a long life is required, the impermeable ventilating brick Become a better choice.

2. Determine the appropriate bottom blowing gas pressure process parameters

According to the data, the minimum bottom blowing gas pressure is equal to the sum of the gas pressure on the liquid surface, the pressure loss of the gas supply pipeline, the additional pressure formed by bubbles, and the static pressure of the molten steel and the slag layer.

If the bottom blowing gas pressure is too small, the bubbles will be difficult to form or the stirring will be too weak.

If the bottom blowing gas pressure is too high, it will result in a decrease in bubble aggregation and dispersion, a decrease in bottom blowing gas utilization and excessive stirring of molten steel, which makes the molten steel too much in contact with the atmosphere during flipping, resulting in aggravated secondary oxidation of the molten steel and a large temperature drop.

The quality of different steel grades determines different steelmaking processes. The most suitable bottom blowing pressure is to meet the steelmaking process’s requirements for gas agitation strength, so that the steel liquid level will roll within an appropriate level, and the inclusions will float up to the greatest extent. At the same time, it can best play the role of ladle covering agent, better ensure that the covering agent absorbs the inclusions carried by air bubbles, and improve the purity of molten steel. In order to more accurately determine the most suitable bottom blowing gas pressure process parameters, a pressure gauge and a flow meter can be installed on the bottom blowing gas pipeline, and the bottom blowing gas pressure and gas supply volume can be determined according to different ladle parameters and metallurgical requirements.

in conclusion

To improve the effect of blowing gas at the bottom of the ladle, choosing high-quality breathable bricks with high thermal shock resistance, permeability resistance and erosion resistance is the first step. The relationship between scientific use and high-quality breathable bricks can be described as complementary