- 31

- May

Dab tsi yog cov laj thawj tseem ceeb uas cuam tshuam rau qhov deformation ntawm high zaus quenching?

Dab tsi yog cov laj thawj tseem ceeb uas cuam tshuam rau deformation ntawm high quenching?

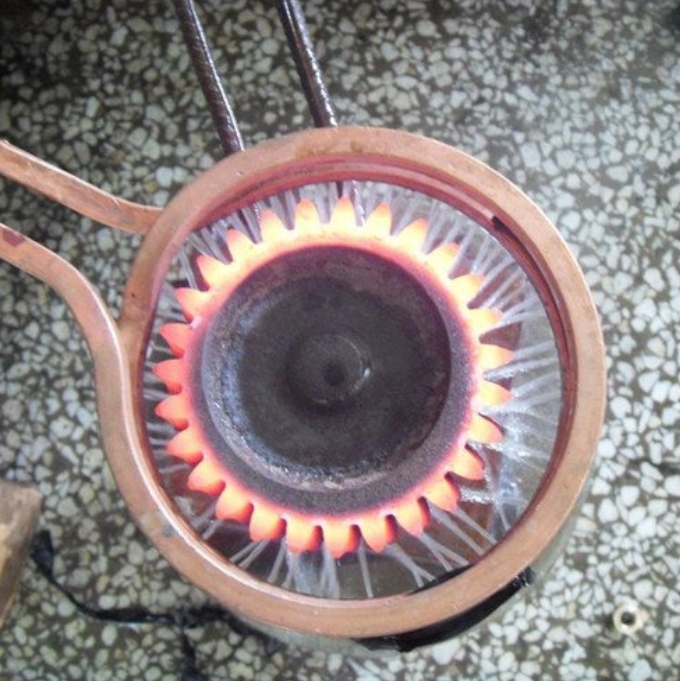

Cov yam ntxwv uas cuam tshuam rau kev deformation ntawm high-frequency quenching tshav kub kev kho mob feem ntau suav nrog cov qauv qub ntawm cov hlau, cov ntsiab lus carbon, qhov loj thiab cov duab ntawm qhov chaw, kev xaiv ntawm quenching nruab nrab, txheej txheem quenching, thiab hardenability ntawm cov hlau.

1. Cov nyhuv ntawm cov ntsiab lus carbon nyob rau hauv steel ntawm deformation ntawm qhov chaw thaum quenching tshav kub kho. Cov pa roj carbon nruab nrab thiab siab siab yog feem ntau ua rau tawg thaum lub sij hawm overheating quenching. Txhawm rau tso qhov deformation thiab tawg, hypereutectoid steels feem ntau siv tsis tiav quenching kom tau txais cryptocrystalline martensite, uas tsis yooj yim los tsim microcracks. .

2. Lub hardenability ntawm steel kuj muaj qee yam cuam tshuam rau lub deformation ntawm qhov chaw thaum quenching tshav kub kho. Lub hardenability ntawm steel yog ze ze rau qhov tseem ceeb txias tus nqi ntawm cov hlau. Qhov qis dua qhov tseem ceeb ntawm qhov txias txias, qhov zoo dua qhov hardenability ntawm cov hlau. Lub ntsiab tseem ceeb los txo qhov tseem ceeb ntawm qhov txias txias yog cov tshuaj muaj pes tsawg leeg ntawm cov hlau. Hlau nrog zoo hardenability tuaj yeem siv qhov nruab nrab quenching nruab nrab thaum quenching thiab txias kom txo tau qhov deformation thiab cracking nyiam ntawm lub workpiece thaum quenching. Yog li ntawd, rau qhov tseem ceeb nrog cov duab nyuaj thiab cov ntu loj, yuav tsum xaiv qhov zoo hardenability. hlau alloy. Tom qab ua hauj lwm thiab tempering, yuav tsum tau txhua yam khoom yuav tsum tau thiab lub deformation thiab cracking yuav txo tau.

3. Kev cuam tshuam ntawm cov qauv qub ntawm cov hlau ntawm quenching deformation ntawm qhov chaw. Lub microstructure ntawm quenched qhov chaw muaj kev cuam tshuam zoo rau quenching zoo ntawm cov khoom. Piv txwv li, alloy steel, bearing steel, thiab lwm yam yuav tsum tau spheroidized annealed tom qab forging. Thaum lub sij hawm quenching thiab cua sov, cov nplej austenite tsis yooj yim kom loj hlob. Lub deformation thiab tawg ntawm lub workpiece yog me me, lub finer lub intrinsic grain loj ntawm cov khoom, lub siab dua lub zog ntawm lub zog, thiab lub zog ntau dua rau deformation, thiab lub deformation ntawm lub workpiece tom qab quenching yog correspondingly txo.

- Cov nyhuv ntawm quenching nruab nrab ntawm deformation ntawm qhov chaw thaum quenching tshav kub kho. Nws yog feem ntau ntseeg hais tias qhov cuam tshuam ntawm qhov cua txias ntawm qhov nruab nrab quenching ntawm 300 ° C ntawm qhov deformation yog qhov tseem ceeb, thiab qhov nruab nrab quenching yuav tsum raug xaiv raws li qhov hardenability ntawm cov hlau, qhov sib txawv ntawm qhov loj ntawm qhov. thiab qhov roughness ntawm qhov chaw, thiab cov duab geometric ntawm qhov cuam tshuam rau quenching deformation ntawm ib feem. , Los ntawm qhov pom ntawm cov txheej txheem kev kho cua sov, cov qauv tsim yog qhov zoo tshaj plaws los siv cov qauv sib luag, tus neeg saib xyuas kom tsis txhob muaj cov kaum ntse ntse, thiab yuav tsum muaj qhov sib npaug ntawm qhov sib npaug. Thaum tsim nyog, qhov zawj rau cov txheej txheem tuaj yeem qhib. Yog li ntawd, cov ntaub ntawv yuav tsum raug xaiv kom tsim nyog kom tsis txhob quenching tawg.