- 31

- May

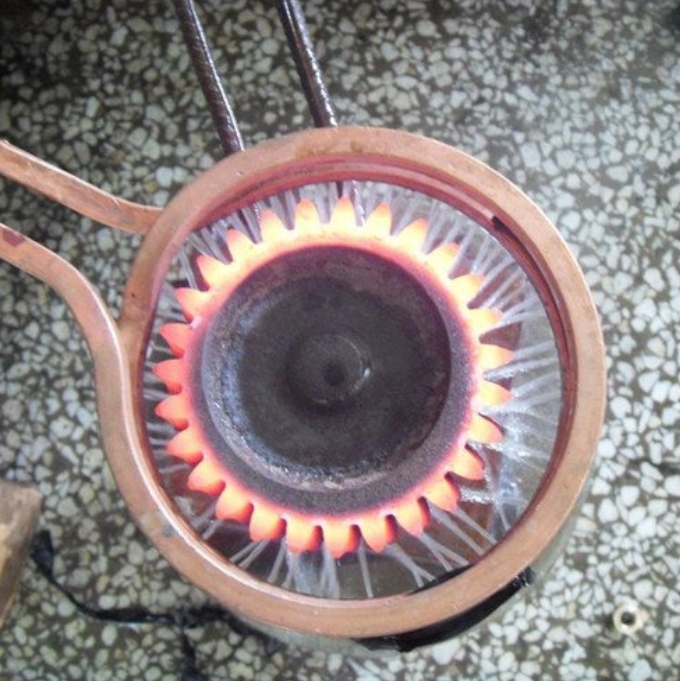

Ziziphi ezona zizathu ziphambili ezichaphazela deformation of high frequency quenching?

Ziziphi izizathu eziphambili ezichaphazela ukuguqulwa kwe ukucima rhoqo?

Izinto ezichaphazela i-deformation ye-high-frequency quenching yonyango lobushushu ikakhulukazi ibandakanya isakhiwo sokuqala sentsimbi, umxholo wekhabhoni, ubungakanani kunye nokuma kwamacandelo, ukukhethwa kwendawo yokucima, inkqubo yokucima, kunye nokuqina kwentsimbi.

1. Umphumo womxholo wekhabhoni kwintsimbi kwi-deformation yamacandelo ngexesha lokucima unyango lobushushu. Iintsimbi eziphakathi kunye nekhabhoni ephezulu zivame ukuqhekeka ngexesha lokucima ukucima. Ukuze ubeke i-deformation kunye nokuqhekeka, iintsimbi ze-hypereutectoid zihlala zisebenzisa ukucima okungagqibekanga ukufumana i-cryptocrystalline martensite, ekungekho lula ukuvelisa i-microcracks. .

2. Ukuqina kwentsimbi kunempembelelo ethile kwi-deformation yamacandelo ngexesha lokucima unyango lobushushu. Ukuqina kwentsimbi kuhambelana ngokusondeleyo nezinga lokupholisa elibalulekileyo lentsimbi. Ukunciphisa izinga lokupholisa elibalulekileyo, ngcono ukuqina kwentsimbi. Into ephambili yokunciphisa izinga lokupholisa elibalulekileyo kukubunjwa kweekhemikhali zentsimbi. Insimbi enobunzima obuhle inokusebenzisa i-moderate medium quenching medium ngexesha lokucima kunye nokupholisa ukunciphisa i-deformation kunye nokuqhekezwa kwe-workpiece ngexesha lokucima. Ngoko ke, kwiindawo ezibalulekileyo ezinemilo enzima kunye namacandelo amakhulu, ukuqina okulungileyo kufuneka kukhethwe. intsimbi yengxubevange. Emva kokukhonza kunye nokutshisa, iipropati ezifunekayo zomatshini zingafumaneka kwaye i-deformation kunye nokuqhekeka kunokunciphisa.

3. Impembelelo yesakhiwo sokuqala sentsimbi kwi-deformation yokucima iindawo. I-microstructure yamacandelo acinyiweyo inempembelelo enkulu kumgangatho wokucima iindawo. Ngokomzekelo, i-alloy steel, intsimbi yokuthwala, njl. Ngexesha lokucima kunye nokufudumala, i-grains ye-austenite ayilula ukukhula. I-deformation kunye nokuqhekeka kwe-workpiece encinci, i-finer ye-intrinsic ye-grain size ye-material, i-high isivuno samandla, kunye nokuchasana okukhulu kwi-deformation, kunye ne-deformation ye-workpiece emva kokucima ngokuhambelanayo.

- Umphumo wokucima i-medium kwi-deformation yamacandelo ngexesha lokucima unyango lobushushu. Ngokuqhelekileyo kukholelwa ukuba impembelelo yesantya sokupholisa kwi-300 ° C kwi-deformation isitshixo, kwaye i-medium quenching kufuneka ikhethwe ngokufanelekileyo ngokobunzima bentsimbi, ubungakanani becandelo elinqamlezayo. kunye noburhabaxa bomphezulu, kunye nemilo yejometri yenxalenye ichaphazela i-deformation yokucima inxalenye. , Ukususela kumbono wenkqubo yokunyanga ukushisa, inxalenye yoyilo ilungele ukusebenzisa isakhiwo esilinganayo, umphathi ugwema iikona ezibukhali, kwaye ufuna icandelo elifanayo ngokugqithisileyo. Xa kuyimfuneko, i-groove yenkqubo inokuvulwa. Ngoko ke, izinto eziphathekayo kufuneka zikhethwe ngokufanelekileyo ukuphepha ukucima iintanda.