- 15

- Sep

Kuenderera mberi kukanda tundish yakanyungudutswa simbi induction kudziyisa michina

Continuous casting tundish molten steel induction heating equipment

1 Overview

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Tundish induction heat yemidziyo ine zvinotevera maitiro:

(1) Kukurumidza kupisa kwekukurumidza uye yakakwira yemagetsi kupisa kunyatsoshanda;

(2) Dzimwe mhando zvakare dzine imwe electromagnetic inosimudzira mhedzisiro, iyo inobatsira kubviswa kweiyo inclusions;

(3) Iyo tembiricha yemaitiro iri nyore kudzora, uye chinonyanya kukosha ndechekunyatso kudzora kupisa kwakanyanya kwesimbi yakanyungudutswa;

(4) Iyo yekupisa simba inoganhurwa nekudzika kweiyo tundish fluid level. Chete kana simbi yakanyungudutswa mu tundish ichiungana kune imwe kudzika, kupisa kunogona kuenderera zvakanaka.

Kune akati wandei marudzi e tundish induction kudziyisa michina:

(1) Zvinoenderana nerudzi rweinductor, inogona kukamurwa kuita coreless induction yekudziya michina uye cored induction yekudziya michina;

(2) Zvinoenderana nechimiro cheinductor, inogona kukamurwa kuita yakawedzera kukanganisa mhando uye tunnel mhando (groove, yakanyungudutswa mugero) induction yekupisa michina;

(3) Zvinoenderana nechikamu chekudziya, chinogona kukamurwa mukudziya kwenzvimbo uye kupisa kwese.

2 Inoenderera mberi ichikanda tundish yakanyungudutswa simbi yemagetsi induction yekudziya mudziyo wemidziyo

2. 1 Tundish electromagnetic induction heat yemidziyo inofananidzwa neyakachinjika inoenderera yekukanda muchina

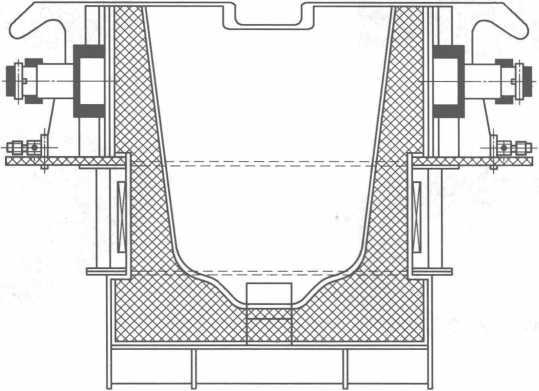

Iyo tundish electromagnetic induction yekudziya yemidziyo inofananidzwa neyakachinjika inoenderera yekukanda muchina inoratidzwa muMufananidzo 10-7.

Nzira yekugadzirwa kwesimbi isina tsvina ikozvino inotsanangurwa.

Mufananidzo 10-7 Tundish electromagnetic induction heat yemidziyo inofananidzwa neyakachinjika inoenderera yekukanda muchina.

Mushure memhando dzese dzesimbi dzisina simbi dzakabatanidzwa, dzinoiswa mumavira matatu e5t induction kubva mutangi rekudyisa nemacranes. Mushure mekunge simbi yakasvibiswa yakanyungudutswa kusvika kune inodiwa tembiricha (inenge 1650 ° C), simbi yakanyungudutswa muchoto chekupinza inodururwa muladle, uye yobva yashandiswa Rori inodurura simbi yakanyungudutswa muchoto che8t AOD, uko inopinda decarburization, slagging, dephosphorization uye kubvisa sarufa, uye kugadziriswa kweiyo alloy kuumbwa (kunyanya Cr, Ni), uyezve simbi yakanyungudutswa (kuumbwa uye tembiricha zvinosangana nezvinodiwa) Isa simbi yakanyungudutswa muladle muladle uye shandisa crane kudurura. iyo simbi yakanyungudutswa muladle mune ladle ye8t electromagnetic induction kudziyisa michina. Iyo simbi isina tsvina inodziya nekuchengetedza kupisa inodhonzwa uye yakakandirwa mubhara rakatenderedzwa nemuchina wakachinjika unoramba uchikandira uye pakupedzisira sundirwa mumubhedha unotonhorera nekugadzira nekugera. .

Mushure memhando dzese dzesimbi dzisina simbi dzakabatanidzwa, dzinoiswa mumavira matatu e5t induction kubva mutangi rekudyisa nemacranes. Mushure mekunge simbi yakasvibiswa yakanyungudutswa kusvika kune inodiwa tembiricha (inenge 1650 ° C), simbi yakanyungudutswa muchoto chekupinza inodururwa muladle, uye yobva yashandiswa Rori inodurura simbi yakanyungudutswa muchoto che8t AOD, uko inopinda decarburization, slagging, dephosphorization uye kubvisa sarufa, uye kugadziriswa kweiyo alloy kuumbwa (kunyanya Cr, Ni), uyezve simbi yakanyungudutswa (kuumbwa uye tembiricha zvinosangana nezvinodiwa) Isa simbi yakanyungudutswa muladle muladle uye shandisa crane kudurura. iyo simbi yakanyungudutswa muladle mune ladle ye8t electromagnetic induction kudziyisa michina. Iyo simbi isina tsvina inodziya nekuchengetedza kupisa inodhonzwa uye yakakandirwa mubhara rakatenderedzwa nemuchina wakachinjika unoramba uchikandira uye pakupedzisira sundirwa mumubhedha unotonhorera nekugadzira nekugera. .

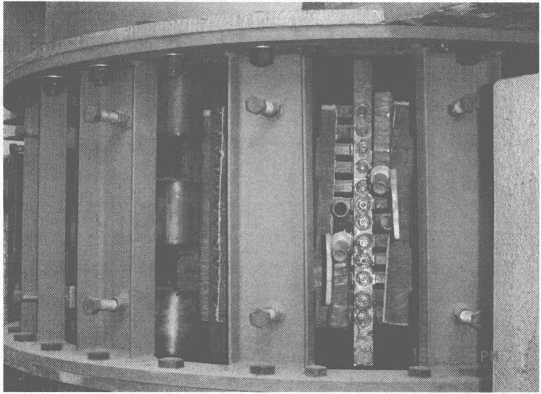

Chinhu chemuviri che8t electromagnetic induction heat equipment ladle inoratidzwa muMufananidzo 10-8.

8t uye 14t tundish electromagnetic induction kudziyisa midziyo, iyo tundish induction yekudziisa michina inogona kunyatso kudzora tembiricha yesimbi yakanyungudutswa (iyo yekukanganisa range ingori ± 5 ~ 6 ℃), nokudaro kuve nechokwadi chemhando yebillet. Uye zvakare, iyo tembiricha yekugadziridza nguva ye tundish inogona zvakare kukwidziridzwa zvakakodzera, ichiratidza maitiro akanaka eiyo induction yekudziya michina.

2. 2 Tundish mudziyo we induction kudziyisa midziyo yearc inoenderera mberi yekukanda muchina

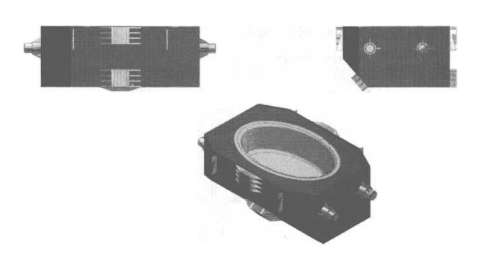

Iyo tundish mudziyo weiyo induction yekudziya midziyo yemuchina wearc unoramba uchikandira unoratidzwa muMufananidzo 10-9.

Mushure meiyo arc billet inoenderera mberi caster inotora iyo electromagnetic induction yekudziya midziyo tundish, tembiricha yekubata inogona kudzikiswa (semuenzaniso, inogona

Mufananidzo 10-9 Tundish mudziyo weiyo induction yekudziya michina yearc inoramba ichikanda muchina

Kubva 1700 ° C kusvika 1650 ° C), izvi hazvingobatsiri kuvandudza hupenyu hwesimbi yekugadzira choto lining (inoshandura, electric arc furnace kana induction furnace), asi zvakare inodzikamisa tembiricha yesimbi yakanyungudutswa mukuramba ichikanda uye inovimbisa kunaka kwekuenderera. kukanda billets.

Zvichienderana nechisumo chiri pamusoro, zvinogona kutariswa kuti inoenderera ichikanda tundish magineti induction kudziyisa michina itsva inochengetedza simba uye inoshamwaridzika tekinoroji. Kugamuchirwa kwechishandiso ichi ipurojekiti yekushandura tekinoroji yemabhizinesi esimbi, uye yakakodzera kusimudzirwa nekushandiswa.

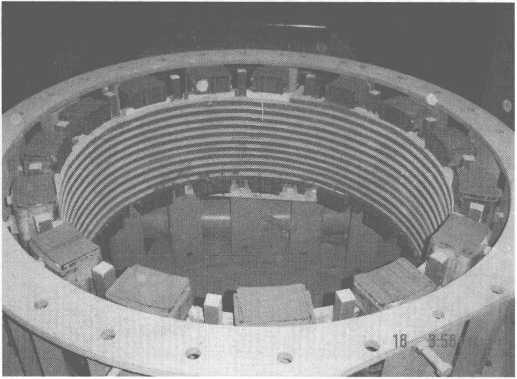

Mufananidzo 10-10 inoratidza iyo 16t tundish electromagnetic induction kudziyisa michina.

Mufananidzo 10-10 16t tundish electromagnetic induction heat equipment

Mufananidzo 10-11 idhizaini yechirongwa che tundish ye14t induction yekudziya michina.

Mufananidzo 10-11 Schematic diagiramu ye tundish ye14t induction yekudziya michina