- 15

- Sep

Ukusakaza okuqhubekayo kwe-tundish encibilikisiwe imishini yokushisa yokungeniswa kwensimbi

Continuous casting tundish molten steel imishini yokushisa yokufakelwa

Ukubuka konke kwe-1

Ubuchwepheshe bemishini yokushisisa yensimbi encibilikisiwe ye-Tundish ithuthukiswa ngenqubekelaphambili yobuchwepheshe bokusakaza obuqhubekayo, ukuthuthukiswa kwezidingo zekhwalithi yensimbi, isidingo sokonga amandla nokunciphisa ukusetshenziswa, kanye nokumataniswa kwezinqubo zokucwenga zangaphandle nezinqubo eziqhubekayo zokuphonsa. Amamaki ensimbi ahlukene anezidingo ezihlukene ku-AT yokushisa okukhulu kwensimbi encibilikisiwe. Ngamapuleti aminyene, ukuze kuncishiswe imifantu yangaphakathi nesikhungo esixegayo, i-AT kufanele ibe phansi (5 ~ 200T); kumapuleti amancane abandayo, indawo engaphezulu iyadingeka ukuze ibe nekhwalithi enhle. Okuphakeme (15~300℃). Kodwa-ke, ukushisa okuphezulu kwensimbi encibilikisiwe kufanele kuzinze phakathi kwebanga elithile ukuze kuncishiswe ukushintshashintsha. Lesi yisimo esidingekayo sokuqinisekisa inqubekelaphambili eshelelayo yokukhiqiza okuqhubekayo, ukuvimbela ukuvaleka kwemibhobho noma ukuvimbela izingozi ezivuzayo, nokuqinisekisa ikhwalithi yama-cast slabs. Ukuthuthukiswa komsebenzi wokushisa we-tundish kwenza kube nokwenzeka ukulawula ukushisa okuphezulu kwensimbi encibilikisiwe ngokuzinzile. Izinga lokushisa lensimbi encibilikisiwe ye-ladle ehlukene liyashintshashintsha, elinomthelela omubi enqubweni eqhubekayo yokuphonsa, futhi ukushisa kwe-tundish kungasinxephezela ngezinga elithile. Kodwa-ke, kufanele kuphawulwe ukuthi ukugcinwa kwe-superheat yensimbi encibilikisiwe ezinzile ikakhulukazi kuncike ezingeni lokushisa elifanele lokuthepha kanye nesakhiwo sokulungisa ngemuva kokuthepha, futhi ukushisa kwe-tundish kungadlala indima eyengeziwe kuphela. Noma kunjalo, ukushisisa nokulawulwa kwensimbi encibilikisiwe ku-tundish kusathola ukunakwa okuvela emphakathini we-metallurgical. Amanye amazwe amelwe i-Japan, i-United States, i-United Kingdom, kanye ne-France aye enze ucwaningo ngokulandelana ngobuchwepheshe bokushisisa insimbi encibilikisiwe ye-tundish kusukela ngeminyaka yawo-1970 kuya ko-1980. Inkampani yase-Japan yase-Kawasaki yaqala yasungula futhi yathola ilungelo lobunikazi lase-Japan kusukela ngo-1982. Njengamanje, ubuchwepheshe bokushisisa bensimbi obuncibilikisiwe be-tundish buthuthukiswe ngempumelelo noma obusathuthukiswa ngokuvamile busebenzisa indlela yokushisisa ngokomzimba. Endleleni yokushisa ngokomzimba, amandla kagesi asetshenziswa njengomthombo wokushisa futhi aguqulwa ngokuya ngamandla kagesi. Izindlela ezihlukene zingahlukaniswa zibe: imishini yokushisa yokungeniswa kwe-electromagnetic, ukushisa kwe-plasma, ukufudumeza kwe-electroslag kanye nobuchwepheshe bokushisa be-ceramic ye-DC.

Imishini yokushisisa ye-Tundish induction inalezi zimpawu ezilandelayo:

(1) Isivinini sokushisa esisheshayo kanye nokusebenza kahle kokushisa kukagesi;

(2) Ezinye izinhlobo ziphinde zibe nomthelela othile wokunyakazisa kazibuthe, ovumela ukususwa kwezinto ezifakiwe;

(3) Izinga lokushisa lenqubo kulula ukulilawula, futhi into ebaluleke kakhulu ukulawula ngokunembe kakhudlwana ukushisa okukhulu kwensimbi encibilikisiwe;

(4) Amandla okushisa anqunyelwe ukujula kwezinga le-tundish liquid. Kuphela lapho insimbi encibilikisiwe ku-tundish iqoqana ekujuleni okuthile, ukushisa kungaqhubeka kahle.

Kunezinhlobo ezimbalwa zemishini yokushisa ye-tundish induction:

(1) Ngokohlobo lwe-inductor, ingahlukaniswa ibe imishini yokushisa yokungeniswa kwe-coreless kanye nemishini yokushisa yokungeniswa kwe-cored;

(2) Ngokuya ngesakhiwo se-inductor, ingahlukaniswa ngohlobo lwephutha olwandisiwe kanye nohlobo lomhubhe (i-groove, umsele oncibilikisiwe) imishini yokushisa yokungeniswa;

(3) Ngokwengxenye yokushisa, ingahlukaniswa ngokufudumeza kwendawo kanye nokushisa okuphelele.

2 Ukusakaza okuqhubekayo kwe-tundish yensimbi encibilikisiwe ye-electromagnetic induction heat device

2. 1 Imishini yokushisisa ye-electromagnetic induction ye-Tundish ehambisana nomshini wokuphonsa ovundlile oqhubekayo

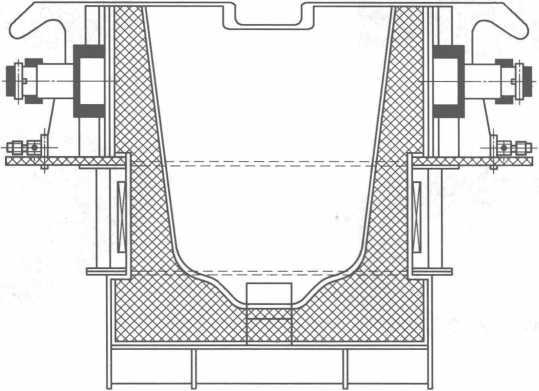

Imishini yokushisa ye-tundish ye-electromagnetic induction ehambisana nomshini wokusakaza ovundlile oqhubekayo uboniswa kuMfanekiso 10-7.

Inqubo yokukhiqiza yesitshalo sensimbi engagqwali isichazwe manje.

Umfanekiso 10-7 Imishini yokushisisa ye-Tundish electromagnetic induction ehambisana nomshini wokuphonsa ovundlile oqhubekayo

Ngemuva kokuthi zonke izinhlobo zensimbi engagqwali zihlanganisiwe, zilayishwa ezithandweni zokungeniswa ze-5t ezintathu ezivela ethangini lokuphakela elinama-cranes. Ngemuva kokuthi insimbi ye-scrap incibilikiswa ekushiseni okudingekayo (cishe i-1650 ° C), insimbi encibilikisiwe esithandweni sokungeniswa ithululelwa ku-ladle, bese isetshenziswa Iloli lithela insimbi encibilikisiwe esithandweni somlilo se-8t AOD, lapho idlula khona i-decarburization, i-slagging, i-dephosphorization kanye nokususwa kwesibabule, nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), bese kuba insimbi encibilikisiwe (ukwakheka kanye nezinga lokushisa kuhlangabezana nezidingo) Faka insimbi encibilikisiwe ku-ladle ku-ladle bese usebenzisa i-crane ukuthulula. insimbi encibilikisiwe ku-ladle ku-ladle ye-8t electromagnetic induction heat heat. Uketshezi lwensimbi engagqwali olushisiswe ukugcinwa kokushisa luyadonswa bese luphonswa kubha eyindilinga ngomshini wokuphonsa oqhubekayo ovundlile futhi ekugcineni luphushelwe embhedeni wokupholisa ngokwakha nokugunda. .

Ngemuva kokuthi zonke izinhlobo zensimbi engagqwali zihlanganisiwe, zilayishwa ezithandweni zokungeniswa ze-5t ezintathu ezivela ethangini lokuphakela elinama-cranes. Ngemuva kokuthi insimbi ye-scrap incibilikiswa ekushiseni okudingekayo (cishe i-1650 ° C), insimbi encibilikisiwe esithandweni sokungeniswa ithululelwa ku-ladle, bese isetshenziswa Iloli lithela insimbi encibilikisiwe esithandweni somlilo se-8t AOD, lapho idlula khona i-decarburization, i-slagging, i-dephosphorization kanye nokususwa kwesibabule, nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), bese kuba insimbi encibilikisiwe (ukwakheka kanye nezinga lokushisa kuhlangabezana nezidingo) Faka insimbi encibilikisiwe ku-ladle ku-ladle bese usebenzisa i-crane ukuthulula. insimbi encibilikisiwe ku-ladle ku-ladle ye-8t electromagnetic induction heat heat. Uketshezi lwensimbi engagqwali olushisiswe ukugcinwa kokushisa luyadonswa bese luphonswa kubha eyindilinga ngomshini wokuphonsa oqhubekayo ovundlile futhi ekugcineni luphushelwe embhedeni wokupholisa ngokwakha nokugunda. .

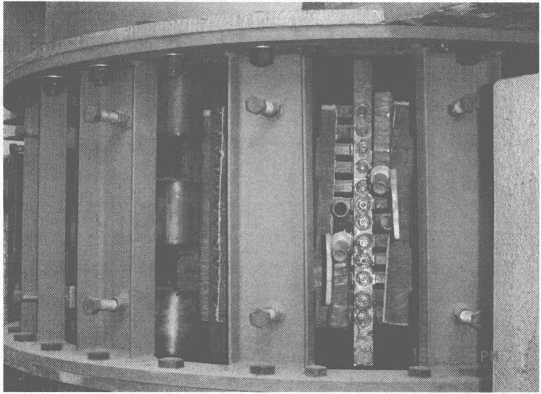

Into ebonakalayo ye-ladle ye-8t ye-electromagnetic induction heat ladle iboniswa kuMfanekiso 10-8.

I-8t kanye ne-14t tundish i-electromagnetic induction heat equipment, imishini yokushisa yokungeniswa kwe-tundish ingalawula ngokuqinile nangokunembile izinga lokushisa lensimbi encibilikisiwe (uhlu lwamaphutha luyi-± 5 ~ 6 ℃ kuphela), ngaleyo ndlela iqinisekise ikhwalithi ye-billet. Ngaphezu kwalokho, isikhathi sokulungiswa kwezinga lokushisa kwe-tundish singanwetshwa ngokufanelekile, sibonise umphumela omuhle wemishini yokushisa yokungeniswa.

2. 2 Idivayisi ye-Tundish yemishini yokushisa yokungeniswa yomshini wokuphonsa we-arc oqhubekayo

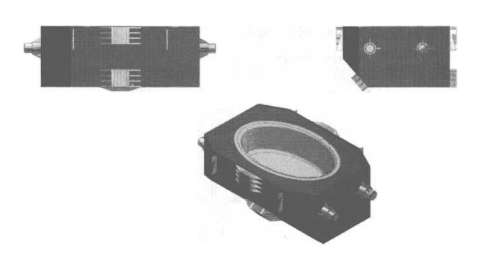

Idivayisi ye-tundish yemishini yokushisa yokungeniswa yomshini wokukhipha i-arc oqhubekayo uboniswa kuMfanekiso 10-9.

Ngemuva kokuthi i-arc billet eqhubekayo i-caster ithatha i-tundish yemishini yokushisa yokungeniswa kwe-electromagnetic, izinga lokushisa lokuthinta lingehliswa (isibonelo, lingaba

Umfanekiso 10-9 Idivayisi ye-Tundish yemishini yokushisa yokungeniswa yomshini wokukhipha i-arc oqhubekayo

Ukusuka ku-1700°C kuya ku-1650°C), lokhu akusizi nje kuphela ukuthuthukisa impilo yolayini lwesithando sokwenza insimbi (i-converter, isithando somlilo se-arc kagesi noma isithando somlilo sokungeniswa), kodwa futhi kumisa izinga lokushisa lensimbi encibilikisiwe ekubunjweni okuqhubekayo futhi kuqinisekisa ikhwalithi eqhubekayo. ukuphonsa billets.

Ngokusekelwe esingenisweni esingenhla, kungacatshangwa ukuthi umshini wokushisa oqhubekayo we-tundish magnetic induction ubuchwepheshe obusha bokulondoloza amandla kanye nobungane bemvelo. Ukwamukelwa kwalolu cingo kuwumsebenzi ofanelekile wokuguqulwa kwezobuchwepheshe kumabhizinisi ensimbi, futhi kufanelekile ukukhuthazwa nokusetshenziswa.

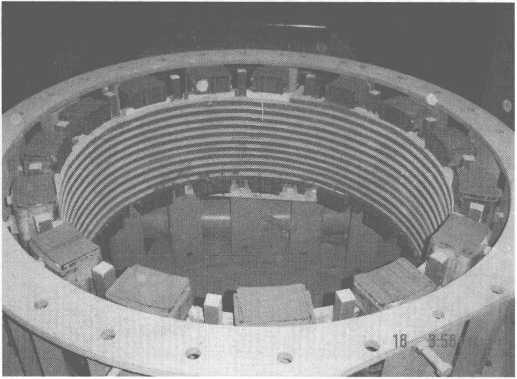

Umfanekiso 10-10 ukhombisa imishini yokushisisa ye-16t tundish electromagnetic induction.

Umfanekiso 10-10 16t tundish i-electromagnetic induction imishini yokushisa

Umfanekiso 10-11 uwumdwebo wohlelo lwe-tundish yemishini yokushisa yokungeniswa kwe-14t.

Umfanekiso 10-11 Umdwebo weSchematic we-tundish ye-14t induction imishini yokushisa