- 15

- Sep

Lisebelisoa tse tsoelang pele tsa ho futhumatsa li-tundish tse entsoeng ka tšepe e entsoeng ka tšepe

Continuous casting tundish molten steel lisebelisoa tsa ho futhumatsa

Kakaretso ea 1

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Lisebelisoa tsa ho futhumatsa tsa Tundish induction li na le litšobotsi tse latelang:

(1) Lebelo la ho futhumatsa ka potlako le katleho e phahameng ea ho futhumatsa motlakase;

(2) Mefuta e meng e boetse e na le phello e itseng ea electromagnetic e susumetsang, e thusang ho tlosoa ha li-inclusions;

(3) Mocheso oa ts’ebetso o bonolo ho o laola, ‘me ntho ea bohlokoa ka ho fetisisa ke ho laola ka mokhoa o nepahetseng ho feta mocheso o moholo oa tšepe e qhibilihisitsoeng;

(4) Matla a ho futhumatsa a lekanyelitsoe ke botebo ba boemo ba mokelikeli oa tundish. Ke feela ha tšepe e qhibilihisitsoeng ka har’a tundish e bokellana ho ea botebong bo itseng, ho futhumatsa ho ka tsoela pele hantle.

Ho na le mefuta e ‘maloa ea lisebelisoa tsa ho futhumatsa tsa tundish induction:

(1) Ho ea ka mofuta oa inductor, e ka aroloa ka lisebelisoa tsa ho futhumatsa tse se nang letho le lisebelisoa tsa ho futhumatsa tse nang le cored;

(2) Ho ea ka sebopeho sa inductor, e ka aroloa ka mofuta o eketsehileng oa phoso le mofuta oa kotopo (groove, foro e entsoeng ka ho qhibilihisoa) thepa ea ho futhumatsa ea induction;

(3) Ho ea ka karolo ea ho futhumatsa, e ka aroloa ho futhumatsa sebakeng le ho futhumatsa ka kakaretso.

2 Sesebelisoa sa ho futhumatsa se sa khaotseng sa tundish se entsoeng ka tšepe ea motlakase ea motlakase

2. 1 Sesebelisoa sa ho futhumatsa sa Tundish sa electromagnetic induction se tsamaellanang le mochini o lahlang o sa khaotseng

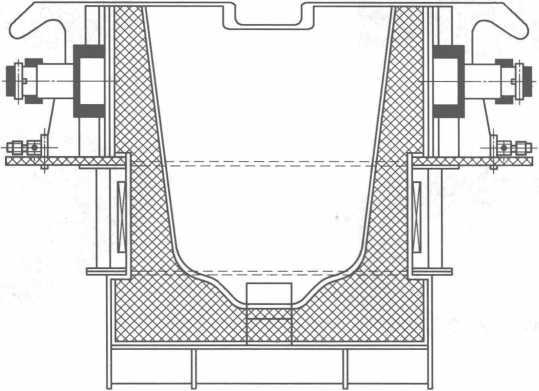

Thepa e futhumatsang ea tundish electromagnetic induction e tsamaellanang le mochini o sa khaotseng oa ho lahla o bonts’itsoe ho Setšoantšo sa 10-7.

Ts’ebetso ea tlhahiso ea semela sa tšepe e sa hloekang e se e hlalositsoe.

Setšoantšo sa 10-7 Sesebelisoa sa ho futhumatsa sa Tundish electromagnetic induction se tsamaellanang le mochini o lahlang o tsoelang pele.

Ka mor’a hore mefuta eohle ea litšepe tse sa hloekang li kopane, li kenngoa ka har’a libopi tse tharo tsa 5t tse tsoang ka tanka ea ho fepa ka li-cranes. Ka mor’a hore tšepe ea tšepe e qhibilihe ho fihlela mocheso o hlokahalang (hoo e ka bang 1650 ° C), tšepe e qhibilihisitsoeng ka sebōping sa induction e tšeloa ka har’a ladle, ebe e sebelisoa Teraka e tšela tšepe e qhibilihisitsoeng ka sebōping sa 8t AOD, moo e kenang teng; slagging, dephosphorization le ho tlosa sebabole, le ho lokisoa ha motsoako oa motsoako (haholo-holo Cr, Ni), ebe tšepe e qhibilihisitsoeng (sebopeho le mocheso li finyella litlhoko) Kenya tšepe e qhibilihisitsoeng ka ladle ka ladle ‘me u sebelise crane ho tšela. tšepe e qhibilihisitsoeng ka har’a ladle ka har’a ladle ea lisebelisoa tsa ho futhumatsa tsa 8t electromagnetic induction. Mokelikeli oa tšepe o sa hloekang o futhumetseng ka ho boloka mocheso o huloa ebe o lahleloa ka har’a bar e chitja ka mochine o tsitsitseng o tsoelang pele oa ho lahlela ‘me qetellong o sutumelletsoa ka betheng e pholileng ka ho etsa le ho kuta. .

Ka mor’a hore mefuta eohle ea litšepe tse sa hloekang li kopane, li kenngoa ka har’a libopi tse tharo tsa 5t tse tsoang ka tanka ea ho fepa ka li-cranes. Ka mor’a hore tšepe ea tšepe e qhibilihe ho fihlela mocheso o hlokahalang (hoo e ka bang 1650 ° C), tšepe e qhibilihisitsoeng ka sebōping sa induction e tšeloa ka har’a ladle, ebe e sebelisoa Teraka e tšela tšepe e qhibilihisitsoeng ka sebōping sa 8t AOD, moo e kenang teng; slagging, dephosphorization le ho tlosa sebabole, le ho lokisoa ha motsoako oa motsoako (haholo-holo Cr, Ni), ebe tšepe e qhibilihisitsoeng (sebopeho le mocheso li finyella litlhoko) Kenya tšepe e qhibilihisitsoeng ka ladle ka ladle ‘me u sebelise crane ho tšela. tšepe e qhibilihisitsoeng ka har’a ladle ka har’a ladle ea lisebelisoa tsa ho futhumatsa tsa 8t electromagnetic induction. Mokelikeli oa tšepe o sa hloekang o futhumetseng ka ho boloka mocheso o huloa ebe o lahleloa ka har’a bar e chitja ka mochine o tsitsitseng o tsoelang pele oa ho lahlela ‘me qetellong o sutumelletsoa ka betheng e pholileng ka ho etsa le ho kuta. .

Ntho e bonahalang ea 8t electromagnetic induction heat equipment ladle e bontšoa ho Setšoantšo sa 10-8.

8t le 14t tundish electromagnetic induction heats equipment, sesebelisoa sa ho futhumatsa sa tundish induction se ka laola ka mokhoa o tiileng le ka nepo mocheso oa tšepe e qhibilihisitsoeng (mofuta oa liphoso ke ± 5 ~ 6 ℃ feela), kahoo o netefatsa boleng ba billet. Ntle le moo, nako ea phetoho ea mocheso oa tundish le eona e ka atolosoa ka nepo, e bonts’a phello e ntle ea lisebelisoa tsa ho futhumatsa tsa induction.

2. 2 Sesebelisoa sa Tundish sa lisebelisoa tse futhumatsang tsa induction tsa mochini oa arc o tsoelang pele oa ho lahla

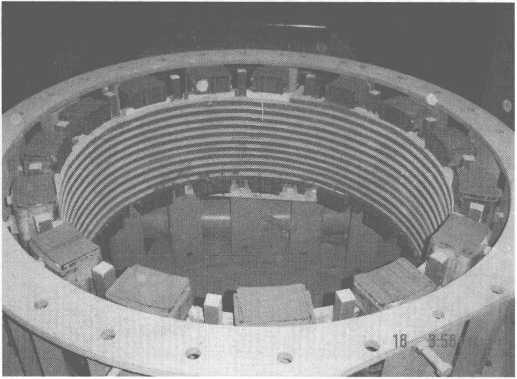

Sesebelisoa sa tundish sa thepa ea ho futhumatsa ea induction ea mochini o tsoelang pele oa arc o bontšoa ho Setšoantšo sa 10-9.

Kamora hore caster e tsoelang pele ea arc billet e nke mochini o futhumatsang oa motlakase oa motlakase, mocheso o ka theoleloa (mohlala, o ka fokotsoa).

Setšoantšo sa 10-9 Sesebelisoa sa Tundish sa lisebelisoa tsa ho futhumatsa tsa induction tsa mochini o tsoelang pele oa arc

Ho tloha ho 1700 ° C ho ea ho 1650 ° C), sena ha se thuse feela ho ntlafatsa bophelo ba sebōpi sa ho etsa tšepe (mofetoleli, sebōpi sa motlakase sa arc kapa sebōpi sa induction), empa hape se tsitsisa mocheso oa tšepe e qhibilihisitsoeng ka ho lahla ho tsoelang pele le ho tiisa boleng ba ho tsoela pele. ho lahla billets.

Ho ipapisitsoe le kenyelletso e kaholimo, ho ka nkuoa hore sesebelisoa sa ho futhumatsa se ntseng se tsoela pele sa tundish ke theknoloji e ncha ea ho boloka matla le tikoloho. Ho amoheloa ha sesebelisoa sena ke morero o batlang o le motle oa phetoho ea theknoloji bakeng sa likhoebo tsa metallurgic, ‘me o tšoaneloa ke ho phahamisoa le ho sebelisoa.

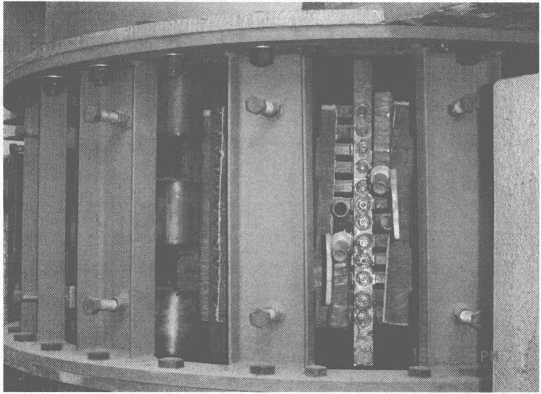

Setšoantšo sa 10-10 se bonts’a lisebelisoa tsa ho futhumatsa tsa 16t tundish electromagnetic induction.

Setšoantšo sa 10-10 16t tundish lisebelisoa tsa ho futhumatsa tsa motlakase oa motlakase

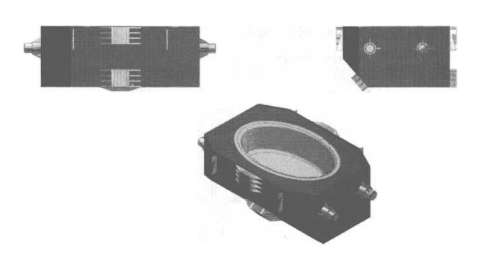

Setšoantšo sa 10-11 ke setšoantšo sa moralo oa tundish ea lisebelisoa tse futhumatsang tsa 14t.

Setšoantšo sa 10-11 Setšoantšo sa moralo oa tundish ea lisebelisoa tse futhumatsang tsa 14t