- 15

- Sep

Tuubitaanka joogtada ah ee tundish birta dhalaalaysa ee qalabka kuleylinta

Continuous casting tundish molten steel Qalabka kululeynta la-galinta

Guudmarka 1

Tignoolajiyada qalabka kululaynta birta dhalaalaysa ee Tundish waxaa lagu horumariyay horumarka tignoolajiyada shubista joogtada ah, hagaajinta shuruudaha tayada birta, baahida loo qabo badbaadinta tamarta iyo dhimista isticmaalka, iyo isbarbardhigga sifaynta dibadda iyo hababka shubista joogtada ah. Heerarka birta ee kala duwan waxay leeyihiin shuruudo kala duwan oo ku saabsan AT ee kulaylka birta dhalaalaysa. Taarikada qaro weyn, si loo yareeyo dildilaaca gudaha iyo xarunta dabacsan, AT waa inuu ahaadaa mid hooseeya (5 ~ 200T); loogu talagalay taarikada khafiifka ah ee qabow-duuban, dusha sare ayaa looga baahan yahay tayada wanaagsan. Sare (15 ~ 300 ℃). Si kastaba ha ahaatee, kulaylka sare ee birta dhalaalaysa waa in lagu dejiyaa ilaa xad go’an si loo yareeyo isbedbeddelka. Tani waa xaalad lagama maarmaan ah si loo hubiyo habsami u socodka wax soo saarka shubista joogtada ah, ka hortagga xannibaadda sanbabada ama ka hortagga shilalka daadinta, iyo hubinta tayada xargaha shubka. Kordhinta shaqada kululaynta ee tundish waxay suurtogal ka dhigaysaa in si adag loo xakameeyo kulaylka sare ee birta dhalaalaysa. Heerkulka birta dhalaalaysa ee laallaalka kala duwan ayaa isbedbedesha, taas oo saameyn xun ku leh habka shubista joogtada ah, iyo kuleylinta tundishku waxay magdhow siin kartaa ilaa xad. Si kastaba ha ahaatee, waa in la tilmaamaa in ilaalinta kulaylka sare ee birta dhalaalaysa ee deggan ay inta badan ku xidhan tahay heerkulka ku habboon tuubada iyo qaab-dhismeedka hagaajinta ka dib marka la garaaco, iyo kuleyliyaha tundish kaliya ayaa ciyaari kara door dheeri ah. Si kastaba ha ahaatee, kulaylinta iyo xakamaynta birta dhalaalaysa ee tundish ayaa weli ah mid dareen ka helaysa bulshada macdanaha ah. Wadamada qaar oo ay matalaan Japan, Maraykanka, Boqortooyada Ingiriiska iyo Faransiiska ayaa si isdaba joog ah u sameeyay cilmi baaris ku saabsan tignoolajiyada kuleylka birta dhalaalaysa ee tundish laga soo bilaabo 1970-meeyadii ilaa 1980-meeyadii. Shirkadda Kawasaki ee Japan ayaa markii ugu horreysay soo saartay oo ay heshay patent-ka Japan horaantii 1982. Hadda, tignoolajiyada kuleylka birta dhalaalaysa ee tundish si guul leh u horumarisay ama ay ku hoos jirto sida caadiga ah waxay qabataa habka kuleylka jirka. Habka kuleylinta jirka, tamarta korontada waxaa loo isticmaalaa isha kulaylka waxaana loo beddelaa iyadoo loo eegayo tamarta korantada. Habab kala duwan ayaa loo qaybin karaa: Qalabka kulaylinta induction electromagnetic, kulaylinta balaasmaha, kulaylinta electroslag iyo DC technology kululaynta dhoobada.

Qalabka kuleylinta induction ee Tundish waxay leedahay sifooyinka soo socda:

(1) Xawaaraha kuleyliyaha degdega ah iyo waxtarka kuleylka korantada oo sarreeya;

(2) Noocyada qaarkood waxay sidoo kale leeyihiin saameyn kicinta korantada, taas oo u sahlaysa ka saarista ku darida;

(3) Heerkulka geeddi-socodka waa sahlan tahay in la xakameeyo, iyo waxa ugu muhiimsan waa in si sax ah loo xakameeyo kulaylka sare ee birta dhalaalaysa;

(4) Awoodda kuleyliyaha waxaa xaddiday qoto dheer ee heerka dareeraha tundish. Kaliya marka birta dhalaalaysa ee tundishku ay ku ururto qoto dheer, kuleylku wuxuu u socon karaa si habsami leh.

Waxaa jira dhowr nooc oo ah qalabka kuleylinta induction tundish:

(1) Marka loo eego nooca inductor, waxaa loo qaybin karaa qalab kuleyliyaha induction-ka aan xudunta lahayn iyo qalabka kuleyliyaha induction-ka;

(2) Marka loo eego qaab-dhismeedka inductor-ka, waxa loo qaybin karaa nooca cilladda oo kordhay iyo nooca tunnel-ka (jeexdin, godad dhalaalaysa) qalabka kuleylinta induction;

(3) Marka loo eego qaybta kuleyliyaha, waxaa loo qaybin karaa kuleyliyaha deegaanka iyo kuleylka guud.

2 Tuubista joogtada ah ee tundish birta dhalaalaysa ee qalabka kuleyliyaha induction electromagnetic

2. 1 Qalabka kuleyliyaha induction ee Tundish oo ku habboon mashiinka shubista joogtada ah ee jiifka ah

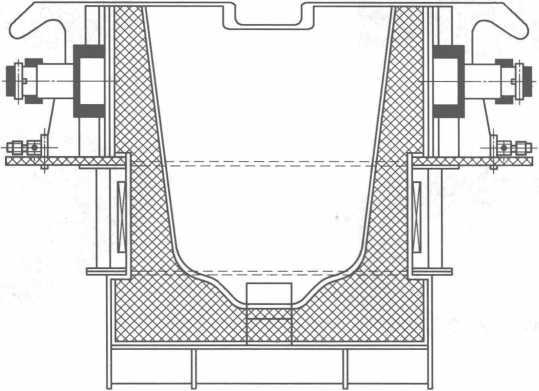

Qalabka kuleylinta soo-saarka korantada ee tundish oo ku habboon mashiinka shubista joogtada ah ee tooska ah ayaa lagu muujiyey Jaantuska 10-7.

Habka wax-soo-saarka ee warshad birta aan lahayn ayaa hadda la sharraxay.

Jaantus 10-7 Qalabka kuleylinta soo-saarka korantada ee Tundish oo ku habboon mashiinka shubista joogtada ah ee jiifka ah

Ka dib marka dhammaan noocyada kala duwan ee birta aan la kala saarin, waxaa lagu shubaa saddex foornooyinka 5t ee foornooyinka quudinta oo leh wiishash. Ka dib markii birta qashinka lagu dhalaaliyo heerkulka loo baahan yahay (qiyaastii 1650 ° C), birta dhalaalaysa ee foornada induction ayaa lagu shubaa godka, ka dibna la isticmaalo Gaarigu wuxuu ku shubaa birta dhalaalaysa foornada 8t AOD, halkaas oo ay marayso decarburization. dharbaaxada, dephosphorization iyo ka saarida baaruud, iyo hagaajinta ka kooban Alloy (inta badan Cr, Ni), ka dibna birta dhalaalaysa (halabuurka iyo heerkulka buuxiyey shuruudaha) Ku rid birta dhalaalaysa ee saqafka dhexda oo isticmaal wiishka si aad ugu shubto. birta dhalaalaysa ee ku dhex jirta suunka dhexda ee 8t qalabka kulaylinta induction electromagnetic. Dareeraha birta ah ee lagu kululeeyo kulaylka ayaa la sawiraa oo lagu tuuray baarka wareegsan mashiinka wax shubida joogtada ah ee joogtada ah oo ugu dambeyntii ku riixay sariirta qaboojinta adoo sameeynaya oo xiiraya. .

Ka dib marka dhammaan noocyada kala duwan ee birta aan la kala saarin, waxaa lagu shubaa saddex foornooyinka 5t ee foornooyinka quudinta oo leh wiishash. Ka dib markii birta qashinka lagu dhalaaliyo heerkulka loo baahan yahay (qiyaastii 1650 ° C), birta dhalaalaysa ee foornada induction ayaa lagu shubaa godka, ka dibna la isticmaalo Gaarigu wuxuu ku shubaa birta dhalaalaysa foornada 8t AOD, halkaas oo ay marayso decarburization. dharbaaxada, dephosphorization iyo ka saarida baaruud, iyo hagaajinta ka kooban Alloy (inta badan Cr, Ni), ka dibna birta dhalaalaysa (halabuurka iyo heerkulka buuxiyey shuruudaha) Ku rid birta dhalaalaysa ee saqafka dhexda oo isticmaal wiishka si aad ugu shubto. birta dhalaalaysa ee ku dhex jirta suunka dhexda ee 8t qalabka kulaylinta induction electromagnetic. Dareeraha birta ah ee lagu kululeeyo kulaylka ayaa la sawiraa oo lagu tuuray baarka wareegsan mashiinka wax shubida joogtada ah ee joogtada ah oo ugu dambeyntii ku riixay sariirta qaboojinta adoo sameeynaya oo xiiraya. .

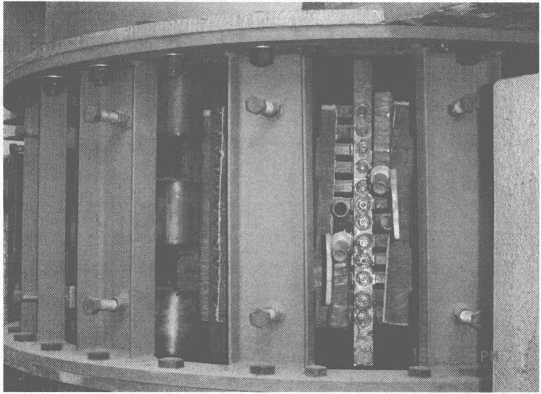

Shayga jireed ee 8t ee qalabka kuleyliyaha induction electromagnetic waxaa lagu muujiyey Jaantuska 10-8.

8t iyo 14t tundish electromagnetic induction qalabka kuleylinta, qalabka kuleylinta induction tundish ayaa si adag oo sax ah u xakameyn kara heerkulka birta dhalaalaysa (kala duwanaanshaha khaladku waa ± 5 ~ 6 ℃), sidaas darteed hubinta tayada billet. Intaa waxaa dheer, wakhtiga hagaajinta heerkulka tundishka ayaa sidoo kale si habboon loo kordhin karaa, taas oo muujinaysa saameynta wanaagsan ee qalabka kuleylinta induction.

2. 2 Qalabka Tundish ee qalabka kuleylka kicinta ee mashiinka tuurista joogtada ah

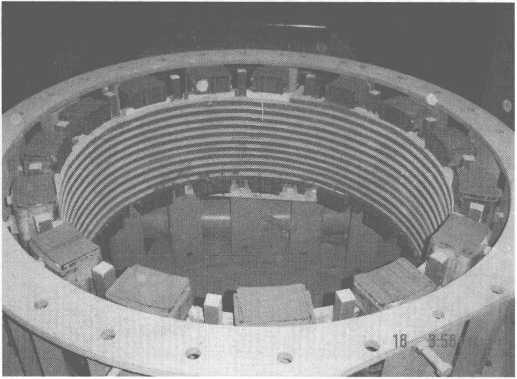

Qalabka tundish ee qalabka kuleyliyaha induction ee mashiinka tuurista joogtada ah ee arc ayaa lagu muujiyay sawirka 10-9.

Ka dib kabka billet-ka joogtada ah uu qaato qalabka kuleyliyaha induction electromagnetic tundish, heerkulka tuubada waa la dhimi karaa (tusaale ahaan, waxay noqon kartaa

Jaantuska 10-9 Qalabka Tundish ee qalabka kuleyliyaha induction ee mashiinka shubka joogtada ah

Laga soo bilaabo 1700 ° C ilaa 1650 ° C), tani kaliya kama caawineyso hagaajinta nolosha dahaarka foornada birta (bedelaha, foornada arc korantada ama foornada induction), laakiin sidoo kale waxay dejisaa heerkulka birta dhalaalaysa ee shubka joogtada ah waxayna dammaanad qaadaysaa tayada joogtada ah tuurista biilasha.

Iyada oo ku saleysan hordhaca sare, waxaa loo qaadan karaa in tuurista joogtada ah ee tundish magnetic induction qalabka kuleylinta ay tahay tignoolajiyad cusub oo tamarta badbaadinaysa iyo deegaanka-saaxiibtinimo. Qaadashada qalabkani waa mashruuc isbeddel teknooloji ah oo ku habboon shirkadaha birta, waana mid mudan in la dhiirrigeliyo lana isticmaalo.

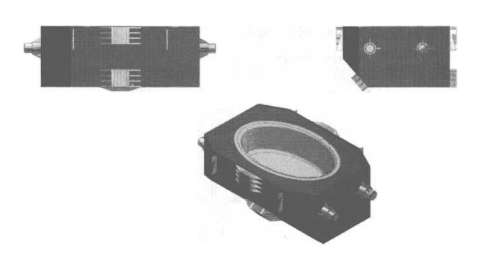

Jaantuska 10-10 wuxuu muujinayaa 16t tundish elektromagnetic induction qalabka kuleylinta.

Jaantus 10-10 16t tundish electromagnetic induction qalab kulaylinta

Jaantuska 10-11 waa jaantus jaantus ah oo ku saabsan tundish ee 14t qalab kulaylinta induction.

Jaantuska 10-11 Jaantuska jaantuska ee tundish ee 14t qalabka kuleylinta induction