- 15

- Sep

kontinyu casting tundish molten steel parabot pemanasan induksi

Continuous casting tundish molten steel alat pemanasan induksi

Tinjauan 1

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Alat pemanasan induksi Tundish gaduh ciri-ciri ieu:

(1) speed pemanasan gancang jeung efisiensi pemanasan listrik tinggi;

(2) Sababaraha jenis ogé mibanda éfék aduk éléktromagnétik tangtu, nu kondusif pikeun ngaleupaskeun inclusions;

(3) Suhu prosés gampang dikontrol, sareng anu paling penting nyaéta langkung akurat ngadalikeun superheat tina baja molten;

(4) Daya pemanasan diwatesan ku jerona tingkat cair tundish. Ngan nalika baja molten dina tundish nu accumulates ka jero nu tangtu, pemanasan bisa lumangsungna lancar.

Aya sababaraha jinis alat pemanasan induksi tundish:

(1) Numutkeun jinis induktor, éta tiasa dibagi kana alat pemanasan induksi inti sareng alat pemanasan induksi inti;

(2) Nurutkeun kana struktur induktor, éta bisa dibagi kana ngaronjat tipe sesar jeung tipe torowongan (alur, lombang molten) parabot pemanasan induksi;

(3) Numutkeun bagian pemanasan, éta bisa dibagi kana pemanasan lokal sarta pemanasan sakabéh.

2 Continuous casting tundish molten steel éléktromagnétik induksi alat alat pemanasan

2. 1 Tundish parabot pemanasan induksi éléktromagnétik loyog jeung mesin casting kontinyu horizontal

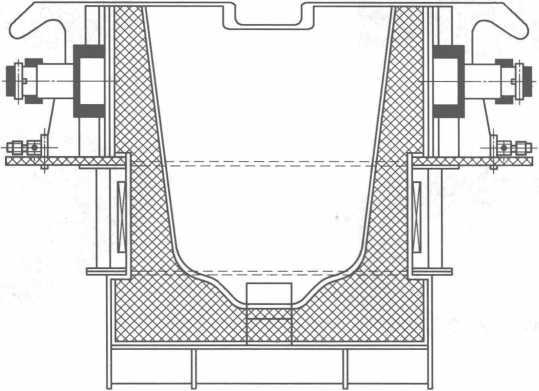

Parabot pemanasan induksi éléktromagnétik tundish cocog sareng mesin casting kontinyu horizontal ditémbongkeun dina Gambar 10-7.

Prosés produksi pabrik stainless steel ayeuna dipedar.

Angka 10-7 Alat pemanasan induksi éléktromagnétik Tundish cocog sareng mesin tuang kontinyu horisontal

Saatos sagala jinis stainless steel anu batched, aranjeunna dimuat kana tilu furnaces induksi 5t ti tank dahar jeung cranes. Saatos baja besi tua dilebur kana suhu anu diperyogikeun (sakitar 1650 ° C), baja molten dina tungku induksi dituang kana ladle, teras dianggo Truk tuang baja molten kana tungku 8t AOD, dimana éta ngalaman dekarburisasi, slagging, dephosphorization sarta panyabutan walirang, sarta adjustment tina komposisi alloy (utamana Cr, Ni), lajeng baja molten (komposisi jeung hawa minuhan sarat) Pasang baja molten dina ladle kana ladle jeung ngagunakeun bango ka tuang. baja molten dina ladle kana ladle tina 8t éléktromagnétik induksi parabot pemanasan. Cairan stainless steel dipanaskeun ku pelestarian panas ieu digambar jeung casted kana bar buleud ku mesin casting kontinyu horizontal sarta tungtungna kadorong kana ranjang cooling ku ngabentuk jeung shearing. .

Saatos sagala jinis stainless steel anu batched, aranjeunna dimuat kana tilu furnaces induksi 5t ti tank dahar jeung cranes. Saatos baja besi tua dilebur kana suhu anu diperyogikeun (sakitar 1650 ° C), baja molten dina tungku induksi dituang kana ladle, teras dianggo Truk tuang baja molten kana tungku 8t AOD, dimana éta ngalaman dekarburisasi, slagging, dephosphorization sarta panyabutan walirang, sarta adjustment tina komposisi alloy (utamana Cr, Ni), lajeng baja molten (komposisi jeung hawa minuhan sarat) Pasang baja molten dina ladle kana ladle jeung ngagunakeun bango ka tuang. baja molten dina ladle kana ladle tina 8t éléktromagnétik induksi parabot pemanasan. Cairan stainless steel dipanaskeun ku pelestarian panas ieu digambar jeung casted kana bar buleud ku mesin casting kontinyu horizontal sarta tungtungna kadorong kana ranjang cooling ku ngabentuk jeung shearing. .

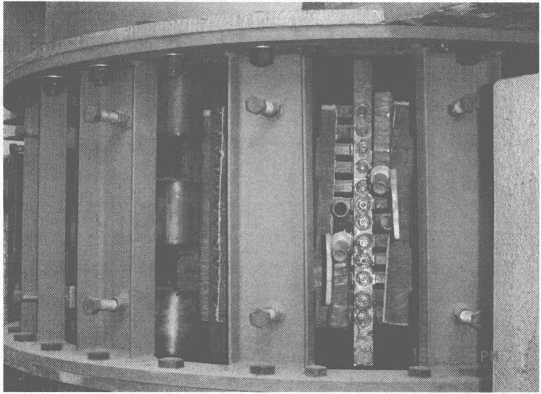

Obyék fisik 8t éléktromagnétik induksi alat pemanasan ladle ditémbongkeun dina Gambar 10-8.

8t sareng 14t alat pemanasan induksi éléktromagnétik tundish, alat-alat pemanasan induksi tundish tiasa mastikeun sareng akurat ngadalikeun suhu baja molten (rentang kasalahan ukur ± 5 ~ 6 ℃), sahingga mastikeun kualitas billet. Salaku tambahan, waktos panyesuaian suhu tundish ogé tiasa diperpanjang, nunjukkeun pangaruh anu hadé tina alat pemanasan induksi.

2. 2 alat Tundish pakakas pemanasan induksi tina arc mesin casting kontinyu

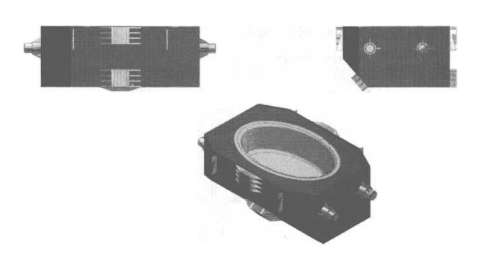

Alat tundish sahiji alat pemanasan induksi tina arc mesin casting kontinyu ditémbongkeun dina Gambar 10-9.

Saatos arc billet caster kontinyu ngadopsi alat pemanasan induksi éléktromagnétik tundish, suhu ngetok tiasa diturunkeun (contona, tiasa

Angka 10-9 Alat Tundish alat pemanasan induksi tina mesin tuang kontinyu

Ti 1700 ° C nepi ka 1650 ° C), ieu teu ngan mantuan pikeun ngaronjatkeun kahirupan steelmaking tungku pinding (converter, tungku arc listrik atawa tungku induksi), tapi ogé stabilizes hawa baja molten dina casting kontinyu sarta jaminan kualitas kontinyu. casting billet.

Dumasar kana bubuka di luhur, éta bisa dianggap yén casting kontinyu tundish alat-alat pemanasan induksi magnét mangrupakeun-hemat énergi anyar jeung téhnologi ramah-lingkungan. Nyoko alat ieu mangrupa proyék transformasi téhnologis rélatif idéal pikeun usaha metalurgi, sarta éta pantes promosi jeung pamakéan.

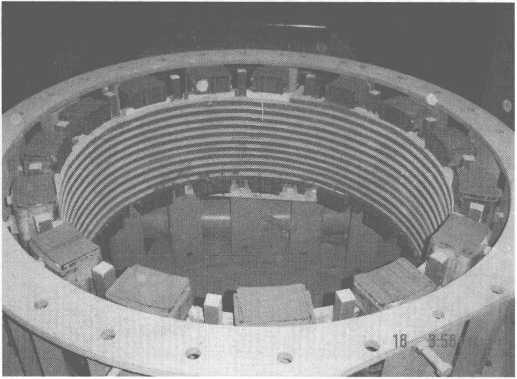

Angka 10-10 nunjukkeun alat pemanasan induksi éléktromagnétik 16t tundish.

Angka 10-10 16t alat pemanasan induksi éléktromagnétik tundish

Angka 10-11 mangrupikeun diagram skéma tina tundish tina alat pemanasan induksi 14t.

Gambar 10-11 diagram skéma tina tundish tina 14t alat pemanasan induksi