- 07

- Sep

Isantya esiphakathi sesithando somlilo esivuthela izitena eziphefumlayo

Isantya esiphakathi sesithando somlilo esivuthela izitena eziphefumlayo

Igama lemveliso:

Isitena esiphefumlayo ukubetha ezantsi kwiziko eliphakathi lesantya esiphakathi

Udidi: Izitena ezinokuphefumla zokuvuthelwa ezantsi kweZiko eliPhakathi eliPhakathi

Iinkcukacha Product

Ukusebenza okuphezulu kweqondo lokushisa izitena zokuphefumla ezantsi kwiziko eliphakathi lesithando somlilo ikakhulu kuxhomekeke kubume bomzimba, beekhemikhali kunye nokwenziwa kwezimbiwa kwezinto ezisetyenzisiweyo. I-Tongyao ngumnikezeli ngezinto zokwenziwa kolu shishino, kwaye ukuveliswa kwezitena zokuphefumla ezantsi emazantsi amaziko aphakathi kuye kwasetyenziswa kakhulu. isicelo.

Ukusetyenziswa kweTekhnoloji yoPhuculo lweBrick enokuPhefumla ngesiBindi esiPhakathi seNdlela

Ngokusetyenziswa kwezitena ezivumayo ukungena emoyeni, sishwankathele ubuchwephesha bokucocwa kweziko eliphakathi, eliguqule ityhilo eliqhelekileyo lokuthanjiswa komlilo ukusuka “kwiikhemikhali zentsimbi” ukuya ekwenzeni intsimbi. Kwiimeko ezininzi, umgangatho wentsimbi etyhidiweyo (taijin) ufikelele kwiziko le-AOD kunye ne-LF yokucoca iziko. , Umgangatho wenqanaba le-VD yokucoca i-degassing furnace.

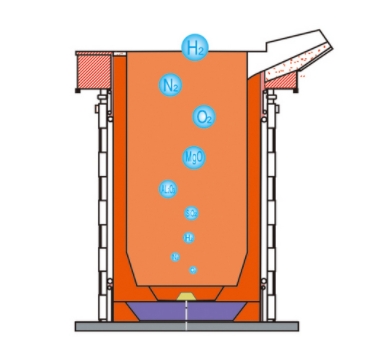

Irhasi efunekayo (enjenge-argon ephezulu yokucoceka) ithunyelwa kwisinyithi esityhidiweyo ngesitena esinokungena emoyeni, kwaye emva kwesixa esithile kunye nexesha lokuhamba, izinto ezifakwayo (ezinje ngeSio2, Al2O3, MgO, njl. kuncitshisiwe. Kwaye 【O 【【N】 【H】 umxholo, kukho iimfuno ezizodwa ezinje xa kususwa, ungavuthela kwi-argon / oksijini igesi exubeneyo, enokuthi inciphise umxholo wekhabhoni ngaphakathi kuluhlu oluthile, xa udibana nesinyithi senitrojeni, uvuthela initrojeni Unokwandisa i-ammonia.

Umgaqo wokusebenza Inkqubo yokucokisa ngokuvuthela igesi yeargon kwisithando somlilo emva kokuba intsimbi inyibilikile. Emva kokuba i-deoxygenation yangaphambi kokuba igqityiwe, emva kwesampulu kunye nohlalutyo, irhasi ephezulu ye-argon yaziswa kwisinyithi esityhidiweyo ngesitena somoya esifakwe emazantsi eziko. Xa irhasi yeargon idlula kwisitena somoya, ineqondo eliphezulu lokusasazeka, lisenza isuntswana elincinci ngesantya esikhulu sokunyuka. Ukuhamba kwe-Bubble, amaqamza angenakubalwa agqitha kwisinyithi esityhidiweyo aya kuvelisa umphumo wokucokiswa. I-bubble nganye ye-argon ngaphakathi kwesinyithi esityhidiweyo yindawo encinci “yegumbi lokucoca”, kunye no-H, O, N kunye nezinye iigesi aziqulathwanga kwibhola ye-argon. Oko kukuthi, uxinzelelo oluyinxalenye lwezi gesi kwibhola ye-argon ilingana no-zero. Xa ibhola ye-argon enoxinzelelo oluphezulu idlula kwisinyithi esinyibilikisiweyo, inyibilikisiwe [H] [O] [N] kunye ne-c0 enganyibilikiyo iya kungena ngokuzenzekelayo kwiqamza le-argon kwaye ilandele i-bubble Vuka kwaye uphuphume. Ukufezekisa injongo ye-degassing.

Emva kokucokiswa, umgangatho kunye nococeko lwentsimbi luphuculwe kakhulu, umahluko we-inclusions ngaphambi nasemva kokucokiswa kuncitshiswe kakhulu, kwaye umxholo wegesi uncitshisiwe kakhulu. Umzekelo ngoku uthelekiswa ngolu hlobo lulandelayo

1. Izinto ezibandakanyiweyo: Inkqubo yovavanyo lweMicroscopic yokungafakwa kwesinyithi kwi-GB10561-2005 yentsimbi

Into ABCD

Isalufa Alumina Silicate Ball oksayidi

Umndilili ngaphambi kokucokiswa 1.8 1.7 1.5 2.1

Umndilili emva kokucokiswa kwe-0.55 0.64 0.5 0.67

Ukunciphisa umndilili% 69 62 67 68

| iprojekthi | A | B | C | D |

| emanzini | Alumina | Umgangatho | Ibhola oksayidi | |

| Umndilili ngaphambi kokucocwa | 1.8 | 1.7 | 1.5 | 2.1 |

| Umyinge emva kokucokiswa | 0.55 | 0.64 | 0.5 | 0.67 |

| Ukunciphisa umyinge% | 69 | 62 | 67 | 68 |

Iziphumo zokulinganisa kanye ziyahlangabezana neemfuno zobugcisa zomgangatho.

2. Umxholo we-hydrogen ungaphantsi kwe-1.0ppm, uhlangabezana neemfuno zensimbi yokufa ≤2.5ppm, kunye namanye amabakala ensimbi ≤3.0ppm.

3. Umxholo weoksijini ungaphantsi kwe-0.0050%.

4. Emva kokuba i-ingot yensimbi iqhutywe, uvavanyo lwe-ultrasonic lufikelele kumgangatho wesibini (GB / T13315-1991).

5. Thelekisa iipropati zoomatshini ezingama-304 zentsimbi engenacingo kunye nangaphandle kokucokiswa: (GB / T328-2002)

1) Amandla aqine yi-549.53Mpa ngaphambi kokucoca kwaye i-606.82Mpa emva kokucokiswa inyuswe nge-57.29Mpa

2) Amandla esivuno yi-270Mpa ngaphambi kokucoca kwaye i-339.52Mpa emva kokucokiswa inyuswe nge-69.52Mpa

3) Nyanzela i-38.46KN ngaphambi kokucokisa i-49.10KN emva kokucokisa ukonyusa nge-10.64KN

Amanqaku ambalwa:

a) Ukusukela ixesha lokuvuthela i-argon kwiziko ngalinye lesinyithi yi-5 ~ 10mm, ukuvuthela kwe-argon kwenziwa emva kokongeza iTaijin. Emva kokuvuthela, ukubetha kwentsimbi akuyi kuchaphazela ixesha lokunyibilikisa kwaye ngekhe kwandise ukusetyenziswa kwamandla.

b) Ukususwa kwe [N] [H] [O] ngokuvuthela irhasi yeargon ayibangeli mpendulo yamachiza, ayizukunciphisa kuphela ubomi bezinto ezomileyo, kodwa ngokuchaseneyo, ubomi besithando somlilo buqhubeka ngenxa kulungelelwaniso lobushushu obunyibilikileyo eziko.

c) IArgon yirhasi yeemvakalelo kwaye ikhuselekile kakhulu ukuyisebenzisa.

Ngamafutshane: Ukufakwa kwetekhnoloji yokucoceka kwesithando esiphakathi okuphawulwe ngokusetyenziswa kwezitena ezingena ngaphakathi emoyeni yinkqubo yemveliso ngotyalo-mali oluphantsi, ukufikelela ngokukhawuleza, ixabiso eliphantsi kunye nomgangatho ophezulu. Yinkqubo yokonga umbane kunye nenkqubo yemveliso enobume bendalo kunye nenkqubo yokuhamba okufutshane. Ngokusekwe kobu buchwephesha, ngokudityaniswa nenkqubo yokukhusela, ukuveliswa komgangatho ophezulu kunye neemveliso zentsimbi zinokuveliswa.