- 07

- Sep

Intermediate frequency furnace argon blowing breathable brick

Intermediate frequency furnace argon blowing breathable brick

product name:

Blow brick at the bottom of intermediate frequency furnace

Category: Breathable Bricks for Blowing at the Bottom of Intermediate Frequency Furnace

Product Details:

The high temperature performance of ventilating bricks for blowing at the bottom of intermediate frequency furnace mainly depends on the physical, chemical properties and mineral composition of the refractory materials used. Tongyao is a supplier of refractory materials for the industry, and the production of ventilating bricks for blowing at the bottom of intermediate frequency furnaces has been widely used. application.

Application of Breathable Brick Refining Technology in Medium Frequency Induction Furnace

Through the use of air-permeable bricks, we have summarized the intermediate frequency induction furnace refining technology, which has transformed the ordinary intermediate frequency induction furnace from “chemical steel” to steelmaking. In many cases, the quality of molten steel (taijin) has reached the AOD furnace and LF refining furnace. , The quality level of VD vacuum degassing furnace refining.

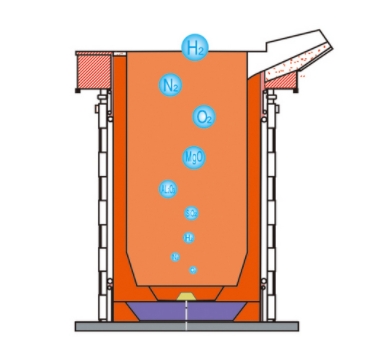

The required gas (such as high-purity argon) is sent to the molten steel through the air-permeable brick, and after a certain amount and time of flow, the inclusions (such as Sio2, Al2O3, MgO, etc.) can be reduced. And 【O】【N】【H】content, there are special requirements such as when decarburization, you can blow in argon/oxygen mixed gas, which can reduce the carbon content within a certain range, when meeting nitrogenous steel, blowing in nitrogen can be Increase ammonia.

Working principle The refining process by blowing argon gas into the induction furnace is after the molten steel is melted. After the pre-deoxygenation is completed, after sampling and analysis, high-purity argon gas is introduced into the molten steel through the ventilating brick installed at the bottom of the furnace. When the argon gas passes through the ventilating brick, it has a high degree of dispersion, forming a small particle with a larger rising speed. Bubble flow, countless bubbles passing through the molten steel will produce a refining effect. Each argon bubble inside the molten steel is a small “vacuum chamber”, and H, O, N and other gases are not contained in the argon bubble. That is to say, the partial pressure of these gases in the argon bubble is equal to zero. When the argon bubble with a high partial pressure passes through the molten steel, the dissolved [H] [O] [N] and the non-dissolved c0 will automatically enter the argon bubble and follow the bubble Rise and overflow. So as to achieve the purpose of degassing.

After refining, the quality and purity of steel are greatly improved, the contrast of inclusions before and after refining is significantly reduced, and the gas content is greatly reduced. An example is now compared as follows

1. Inclusions: Microscopic evaluation method for non-metallic inclusions in steel GB10561-2005

Item A B C D

Sulfide Alumina Silicate Ball Oxide

Average before refining 1.8 1.7 1.5 2.1

Average after refining 0.55 0.64 0.5 0.67

Average reduction% 69 62 67 68

| project | A | B | C | D |

| Sulfide | Alumina | Silicate | Ball Oxide | |

| Average before refining | 1.8 | 1.7 | 1.5 | 2.1 |

| Average after refining | 0.55 | 0.64 | 0.5 | 0.67 |

| Average reduction% | 69 | 62 | 67 | 68 |

The actual measurement results meet the technical requirements of the standard.

2. The hydrogen content is less than 1.0ppm, meeting the requirements of die steel ≤2.5ppm, and other steel grades ≤3.0ppm.

3. The oxygen content is less than 0.0050%.

4. After the steel ingot is processed, the ultrasonic testing has reached the second standard of (GB/T13315-1991).

5. Comparison of the mechanical properties of 304 stainless steel with and without refining: (GB/T328-2002)

1) The tensile strength is 549.53Mpa before refining and 606.82Mpa after refining is increased by 57.29Mpa

2) The yield strength is 270Mpa before refining and 339.52Mpa after refining is increased by 69.52Mpa

3) Force 38.46KN before refining 49.10KN after refining Increase by 10.64KN

A few notes:

a) Since the argon blowing time for each furnace of steel is 5~10mm, argon blowing is carried out after adding Taijin. After blowing, the steel tapping will not affect the smelting time and will not increase the power consumption.

b) Blowing argon to remove [N][H][O] will not cause a chemical reaction, not only will not shorten the life of the furnace lining, but will extend the life of the furnace lining to achieve the homogenization of the melt temperature in the furnace.

c) Argon is an emotional gas and is very safe to use.

In short: the intermediate frequency induction furnace refining technology marked by the use of breathable bricks is a production process with low investment, quick results, low cost and good quality. It is an energy-saving and environmentally-friendly production process and a short-flow production process. Based on this technology, combined with a protective casting process, high-quality castings and steel can be produced.