- 06

- Apr

Power frequency heating hot assembly and hot unloading of bearing inner ring

Power frequency heating hot assembly and hot unloading of bearing inner ring

The inner ring of the bearing is sleeved on the shaft, and the inner ring and the shaft are fixed together by the interference fit of the shaft to the hole. The inner ring expands after heating, so that it can be easily put on the shaft. After cooling, the shaft is tightened. After a certain period of use, the inner ring is worn out and needs to be replaced. In the past, a puller was used to pull the inner ring from the shaft, which would strain the surface of the shaft. If the inner ring on the shaft can be heated quickly, the diameter of the shaft will not expand or be very large due to the expansion of the inner ring. With less increase, the inner ring can be removed from the shaft. This is the so-called thermal unloading. The surface of the shaft will not be strained, and it can be reused without repair.

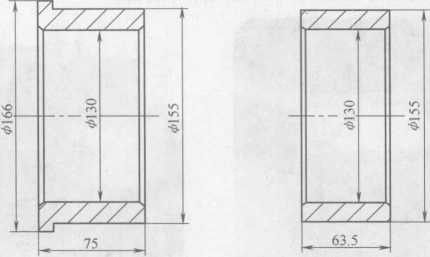

A bearing inner ring for railway locomotive axles is shown in Figure 12-62. It consists of two rings, which are installed one by one when the shaft is installed, and the two rings are removed at the same time when it is removed from the shaft. The masses of the two inner rings are 3.54kg and 2.77kg respectively, and the heating temperature for hot loading and hot unloading is required to be 130Y.

The inner ring of the bearing can be hot-mounted on the shaft as long as the heating temperature reaches 130°C. As for the length of the heating time

The inner ring of the bearing can be hot-mounted on the shaft as long as the heating temperature reaches 130°C. As for the length of the heating time

Figure 12-62 Bearing inner ring

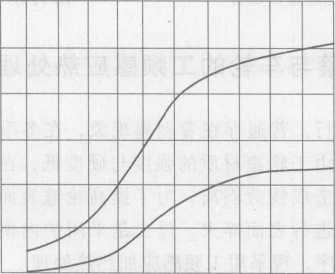

It doesn’t matter much, but to remove the bearing inner ring from the shaft thermally, the length of time with the power frequency induction heating is very important. If the heating time is long, the shaft will also heat up, and it will be difficult to remove the inner ring of the bearing. Figure 12-63 shows the relationship between bearing inner diameter and induction heating time, which can be used as a reference for selecting induction heating time during design calculations.。

Figure 12-63 Heating time for thermal unloading of bearing inner ring

Figure 12-64 shows the power frequency induction heating equipment for hot-loading and hot-unloading heating of the bearing inner ring. The left side of the figure is the power frequency inductor, and the right side is the electrical control cabinet. The coil of the power frequency inductor is made of 3.28mm X 8.6mm pure copper wire. The inner diameter of the coil is 74mm. On the outside of the coil, there are 12 sets of magnetic conductors laminated with silicon steel sheets. The two ends are fastened with steel plates and assembled on a seat. The seat is equipped with 4 rollers to move the inner ring off the shaft during heat unloading. The electric control cabinet is equipped with indicator lights, time relays and AC contactor, etc., used to control the power-on and power-off time of the inductor. When the power frequency inductor is working, the voltage is 380V, the current is 88A, and the power is 21kW. The bearing inner ring can be heated for 30s to 130Y, and the bearing inner ring can be removed from the shaft.