- 01

- Sep

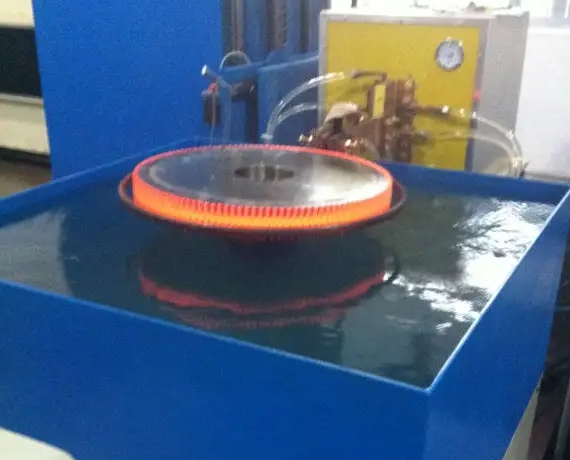

Fa’idodin aikace-aikacen babban tanderun dumama

Amfanin aikace-aikacen high mita dumama makera

1. Surface quenching a high-mita dumama makera: Surface quenching sa workpiece da wuya m harsashi da kuma tauri core. Saboda haka, zai iya maye gurbin wani ɓangare na carburizing, tempering da nitriding matakai, ceton da alloying abubuwa na kayan. Saboda ɗan gajeren lokacin dumama, ƙarancin sikelin oxide da ƙarancin lalacewa.

2. Za’a iya aiwatar da wani ɓangaren quenching na workpiece, wanda zai iya yin zafi daidai da ɓangaren kayan aikin da ake buƙatar kashewa, musamman ma lokacin da aka yi amfani da madubi na Magnetic kuma ana amfani da babban ƙarfin wuta.

3. Maganin zafi mai ceton makamashi yana da babban fa’ida a cikin amfani da makamashi idan aka kwatanta da carburizing, nitriding, da quenching da tempering. Lokacin da bambanci tsakanin ingancin quenched part na workpiece da overall ingancin ne mafi girma, da abũbuwan amfãni ne mafi muhimmanci. Jiyya mai zafi na shigar da sau da yawa yana da ƙarin ƙima.

4. Maganin zafi mai sauri, lokacin dumama na hardening induction ana auna shi a cikin dakika, gabaɗaya a cikin 2-10S, kuma tsarin samarwa shima gajere ne, musamman a yanayin yanayin zafi ko induction tempering, wannan tsari yayi kama da tsarin injin. Don wannan, an shirya kayan aikin ƙarfafawa na zamani akan layin samarwa ko layin atomatik.

5. Tsaftace maganin zafi. Ruwan kashewa da ake amfani da shi wajen kashewar shigar da ruwa gabaɗaya ruwa ne ko kuma maganin ruwa mai ruwa da ƙari. A lokacin quenching, kusan babu hayaƙin mai kuma yanayin aiki yana da kyau.

6. Ya dace da injina da sarrafa kansa, kuma ɓangarorin da aka kera na induction mai ƙarfi gabaɗaya an sanye su da kayan aiki masu dacewa, kamar kayan aikin injin CNC, manipulators, da sauransu.