- 01

- Sep

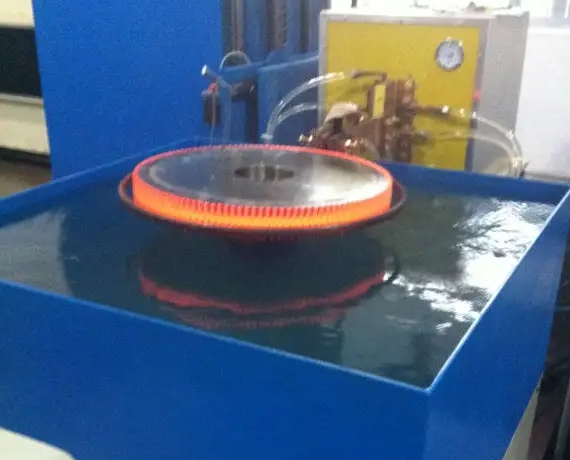

Uru ngwa nke nnukwu ọkụ ọkụ ọkụ ugboro ugboro

Ngwa uru nke nnukwu ọkụ ọkụ ọkụ

1. N’elu quenching na elu-ugboro kpo oku oku: N’elu quenching na-eme ka workpiece nwere ike mpụta shei na a siri ike isi. Ya mere, ọ nwere ike dochie akụkụ nke carburizing, tempering na nitriding usoro, na-azọpụta ihe alloying nke ihe onwunwe. N’ihi obere oge kpo oku, obere ọnụọgụ oxide na obere nrụrụ.

2. Enwere ike ịmechapụ akụkụ akụkụ nke workpiece, nke nwere ike ikpo ọkụ n’ụzọ ziri ezi nke akụkụ nke workpiece nke kwesịrị imenyụ, karịsịa mgbe a na-eji onye na-eduzi magnetik na-eji ike dị elu.

3. Ngwọta okpomọkụ na-azọpụta ike nwere nnukwu uru na oriri ume ma e jiri ya tụnyere carburizing, nitriding, na quenching na tempering. Mgbe ọdịiche dị n’etiti àgwà nke akụkụ ahụ mebiri emebi nke workpiece na àgwà zuru oke dị ukwuu, uru ya dị ịrịba ama. Ọgwụgwọ ọkụ induction na-enwekarị uru agbakwunyere.

4. Ngwọta ọkụ ngwa ngwa, a na-atụle oge ikpo ọkụ nke induction hardening na sekọnd, n’ozuzu n’ime 2-10S, na usoro mmepụta ahụ dịkwa mkpụmkpụ, karịsịa n’ihe gbasara iwe ọkụ ma ọ bụ induction tempering, usoro a yiri usoro nhazi. Iji mezuo nke a, a haziri akụrụngwa ihe ike induction ọgbara ọhụrụ na ahịrị mmepụta ma ọ bụ ahịrị akpaka.

5. Ọcha ọgwụgwọ okpomọkụ. Mmiri na-emenyụ emenyụ nke a na-eji na induction quenching bụ mmiri n’ozuzu ya ma ọ bụ ngwọta mmiri nwere ihe mgbakwunye. N’oge a na-emenyụ ọkụ, ọ fọrọ nke nta ka ọ bụrụ na ọ dịghị uzu mmanụ na ebe ọrụ dị mma.

6. Ọ na-adabara maka mechanization na akpaaka, yana akụkụ ndị siri ike na-emepụta ihe na-emepụta ọtụtụ ihe na-ejikọta ya na ngwá ọrụ kwekọrọ, dị ka CNC hardening machine equipment, manipulators, etc.