- 01

- Sep

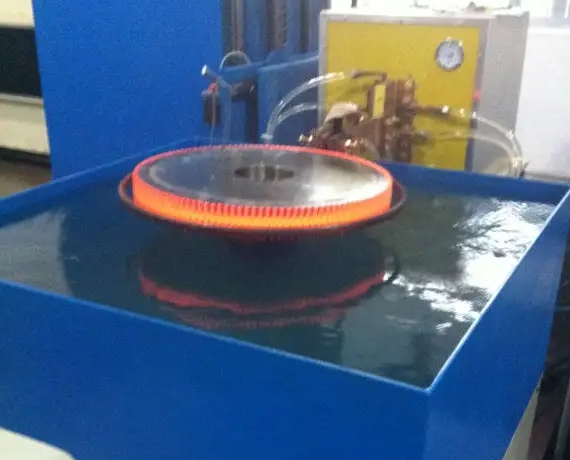

Izinzuzo Isicelo of high frequency bafudumale isithando somlilo

Izinzuzo zohlelo lokusebenza ze isithando somlilo esishisayo

1. Ukucisha ubuso esithandweni sokushisa esinemvamisa ephezulu: Ukucisha ubuso kwenza umsebenzi ube negobolondo langaphandle eliqinile kanye nomgogodla oqinile. Ngakho-ke, ingathatha indawo yezinqubo ze-carburizing, tempering kanye ne-nitriding, isindisa izakhi ze-alloying zento. Ngenxa yesikhathi esifushane sokushisa, isikali se-oxide sincane kanye nokuguqulwa okuncane.

2. Ukucisha ingxenye ye-workpiece kungenziwa, okungashisa ngokunembile ingxenye yomsebenzi odinga ukucinywa, ikakhulukazi uma kusetshenziswa umqhubi kazibuthe futhi kusetshenziswe amandla amakhulu.

3. Ukwelashwa kokushisa okonga amandla kunezinzuzo ezinkulu ekusetshenzisweni kwamandla uma kuqhathaniswa ne-carburizing, i-nitriding, kanye nokucisha kanye nokushisa. Lapho umehluko phakathi kwekhwalithi yengxenye ecishiwe ye-workpiece kanye nekhwalithi iyonke inkulu, izinzuzo zayo zibaluleke kakhulu. Ukwelashwa kokushisa kokungeniswa kuvame ukuba nenani eliphakeme elengeziwe.

4. Ukwelashwa okushisa okusheshayo, isikhathi sokushisa sokuqina kokungeniswa silinganiswa ngemizuzwana, ngokuvamile phakathi kwe-2-10S, futhi umjikelezo wokukhiqiza nawo ufushane, ikakhulukazi esimweni sokushisa noma ukufudumala kwe-induction, le nqubo ifana nenqubo yomshini. Kuze kube manje, imishini yesimanje yokuqinisa induction ihlelwe kulayini wokukhiqiza noma umugqa othomathikhi.

5. Ukwelashwa kokushisa okuhlanzekile. Uketshezi lokucisha olusetshenziswa ekucimeni kokungeniswa ngokuvamile lungamanzi noma isixazululo esinamanzi esinezithasiselo. Ngesikhathi sokucisha, cishe akukho ntuthu kawoyela futhi indawo yokusebenza ilungile.

6. Ilungele ukwenziwa kwemishini kanye ne-automation, futhi izingxenye eziqinile zokungeniswa ezikhiqizwa ngobuningi ngokuvamile zifakwe amathuluzi ahambisanayo, njengamathuluzi omshini wokuqinisa i-CNC, ama-manipulators, njll.