- 01

- Sep

Mabhenefiti ekushandisa emhando yepamusoro yekupisa vira

Application zvakanakira high frequency kudziyisa choto

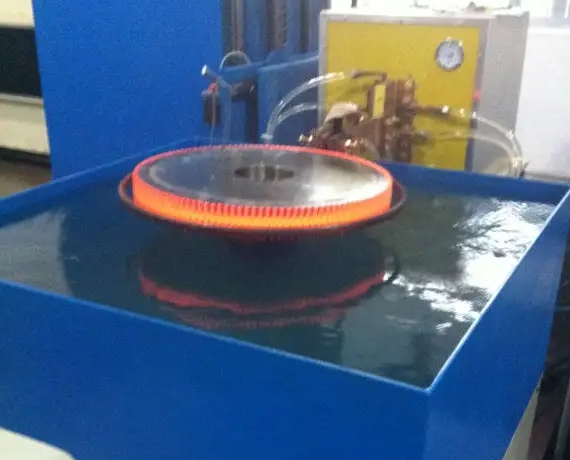

1. Surface quenching in high-frequency heat firnace: Surface quenching inoita kuti workpiece ive negoko rekunze rakaoma uye core yakaoma. Naizvozvo, inogona kutsiva chikamu cheiyo carburizing, kupisa uye nitriding maitiro, ichichengetedza iyo alloying zvinhu zvezvinhu. Nekuda kwenguva pfupi yekudziya, shoma oxide chiyero uye kushoma deformation.

2. Kudzimwa kwechikamu chekushanda kunogona kuitwa, iyo inogona kunyatsopisa chikamu chebasa rinoda kudzima, kunyanya kana magnetic conductor inoshandiswa uye simba guru rinoshandiswa.

3. Kurapa kupisa kwekuchengetedza magetsi kune zvakanakira mukushandiswa kwesimba kana zvichienzaniswa necarburizing, nitriding, uye quenching and tempering. Apo mutsauko pakati pehutano hwechikamu chakadzimwa chebasa rekushanda uye hutano hwese hwakakura, zvakanakira zvaro zvinonyanya kukosha. Induction kupisa kurapwa kazhinji kune yakawedzera kukosha.

4. Kurumidza kupisa kupisa, nguva yekupisa yekuomesa induction inoyerwa mumasekonzi, kazhinji mukati me2-10S, uye kutenderera kwekugadzira zvakare kupfupi, kunyanya mune yekupisa kana induction tempering, iyi nzira yakafanana neyekugadzira machining process. Kuti izvi zviitike, yemazuva ano induction yekuomesa michina yakarongerwa pamutsetse wekugadzira kana otomatiki mutsara.

5. Kuchenesa kupisa kurapwa. Mvura yekudzima inoshandiswa mukudzimisa induction kazhinji imvura kana mhinduro ine aqueous ine additives. Panguva yekudzima, panenge pasina utsi hwemafuta uye nzvimbo yekushanda yakanaka.

6. Yakanakira kugadzira uye otomatiki, uye iyo yakawanda-yakagadzirwa induction yakaomeswa zvikamu zvinowanzo shongedzerwa zvinoenderana nemidziyo, senge CNC yekuomesa muchina maturusi, manipulators, nezvimwe.