- 01

- Sep

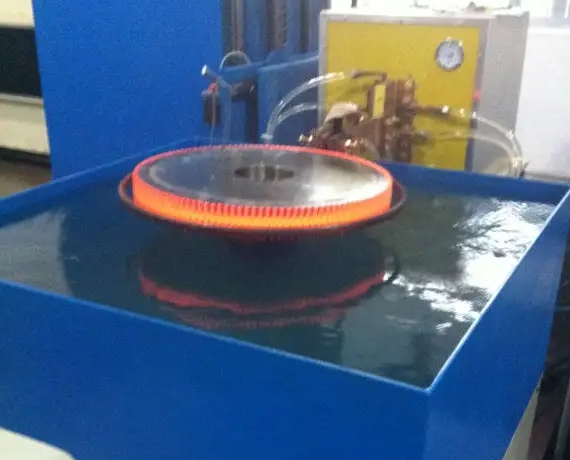

Application advantages of high frequency heating furnace

Application advantages of high frequency heating furnace

1. Surface quenching in high-frequency heating furnace: Surface quenching makes the workpiece have a hard outer shell and a tough core. Therefore, it can replace part of the carburizing, tempering and nitriding processes, saving the alloying elements of the material. Due to the short heating time, less oxide scale and less deformation.

2. Partial quenching of the workpiece can be carried out, which can accurately heat the part of the workpiece that needs to be quenched, especially when a magnetic conductor is used and a high power density is used.

3. Energy-saving heat treatment has great advantages in energy consumption compared with carburizing, nitriding, and quenching and tempering. When the difference between the quality of the quenched part of the workpiece and the overall quality is greater, its advantages are more significant. Induction heat treatment is often of high added value.

4. Rapid heat treatment, the heating time of induction hardening is measured in seconds, generally within 2-10S, and the production cycle is also short, especially in the case of tempering or induction tempering, this process is similar to the machining process. To this end, modern induction hardening equipment has been arranged on the production line or automatic line.

5. Clean heat treatment. The quenching liquid used in induction quenching is generally water or an aqueous solution with additives. During quenching, there is almost no oil fume and the working environment is good.

6. It is convenient for mechanization and automation, and the mass-produced induction hardened parts are generally equipped with corresponding tooling, such as CNC hardening machine tools, manipulators, etc.