- 01

- Sep

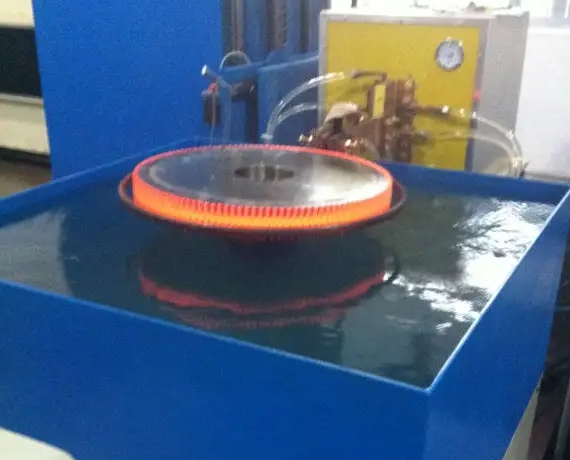

Iinzuzo zesicelo se-furnace ephezulu yokufudumeza

Iinzuzo zesicelo ze high frequency ukufudumeza eziko

1. Ukucima umphezulu kwisithando somlilo esinesantya esiphezulu: Ukucinywa komphezulu kwenza i-workpiece ibe neqokobhe langaphandle eliqinileyo kunye nondoqo onzima. Ke ngoko, inokutshintsha indawo yenkqubo ye-carburizing, tempering kunye ne-nitriding, igcina i-alloying element zemathiriyeli. Ngenxa yexesha elifutshane lokufudumeza, isikali esincinci se-oxide kunye ne-deformation encinci.

2. Ukucinywa kwenxalenye ye-workpiece kunokwenziwa, okunokuthi kushushu ngokuchanekileyo inxalenye yomsebenzi omele ucinywe, ngakumbi xa kusetyenziswa umqhubi wamagnetic kwaye ubuninzi bamandla busetyenziswa.

3. Ukonga ubushushu bonyango kunoncedo olukhulu ekusetyenzisweni kwamandla xa kuthelekiswa ne-carburizing, i-nitriding, kunye nokucima kunye nokuthoba. Xa umehluko phakathi komgangatho wecandelo elicinyiweyo lomsebenzi kunye nomgangatho jikelele mkhulu, iinzuzo zayo zibaluleke kakhulu. Unyango lokungeniswa kobushushu luhlala lunexabiso eliphezulu elongezelelweyo.

4. Unyango olukhawulezayo lokushisa, ixesha lokufudumeza lokuqina kwe-induction lilinganiswa ngemizuzwana, ngokuqhelekileyo ngaphakathi kwe-2-10S, kwaye umjikelezo wemveliso ufutshane, ngakumbi kwimeko yokufudumala okanye ukufudumala, le nkqubo ifana nenkqubo yokucoca. Ukuza kuthi ga ngoku, izixhobo zanamhlanje zokuqiniswa kwe-induction zilungiselelwe kumgca wokuvelisa okanye umgca ozenzekelayo.

5. Unyango olucocekileyo lobushushu. Ulwelo lokucima olusetyenziselwa ukucima i-induction ngokuqhelekileyo ngamanzi okanye isisombululo esinamanzi kunye nezongezo. Ngexesha lokucima, akukho phantse umsi weoli kwaye indawo yokusebenza ilungile.

6. Kukulungele umatshini kunye ne-automation, kunye ne-mass-produced induction parts hardened ngokubanzi zixhotyiswe ngezixhobo ezihambelanayo, ezifana nezixhobo ze-CNC ezilukhuni, ii-manipulators, njl.