- 01

- Sep

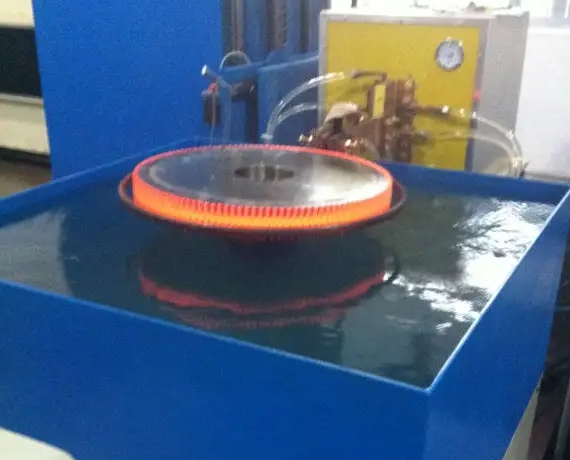

Daim ntawv thov qhov zoo ntawm cov cua kub zaus ntau zaus

Daim ntawv thov zoo ntawm high zaus cua sov rauv

1. Nto quenching nyob rau hauv high-frequency cua sov rauv: Nto quenching ua rau lub workpiece muaj ib tug tawv txheej plhaub thiab ib tug tawv core. Yog li ntawd, nws tuaj yeem hloov ib feem ntawm cov txheej txheem carburizing, tempering thiab nitriding, txuag cov alloying ntsiab ntawm cov khoom. Vim lub sij hawm cua sov luv, tsawg oxide nplai thiab tsawg deformation.

2. Ib nrab quenching ntawm lub workpiece tuaj yeem ua tau, uas tuaj yeem ua kom sov ib feem ntawm lub workpiece uas yuav tsum tau quenched, tshwj xeeb tshaj yog thaum siv cov hlau nplaum sib nqus thiab siv lub zog loj.

3. Kev siv hluav taws xob txuag hluav taws xob muaj txiaj ntsig zoo hauv kev siv hluav taws xob piv nrog carburizing, nitriding, thiab quenching thiab tempering. Thaum qhov sib txawv ntawm qhov zoo ntawm qhov quenched ib feem ntawm lub workpiece thiab tag nrho cov zoo yog ntau dua, nws qhov zoo yog qhov tseem ceeb. Kev kho cua sov induction feem ntau yog tus nqi ntxiv.

4. Kev kho cua sov sai, lub sij hawm cua sov ntawm induction hardening yog ntsuas nyob rau hauv vib nas this, feem ntau nyob rau hauv 2-10S, thiab lub voj voog ntau lawm kuj luv, tshwj xeeb tshaj yog nyob rau hauv cov ntaub ntawv ntawm tempering los yog induction tempering, cov txheej txheem no zoo ib yam li cov txheej txheem machining. Txog rau qhov kawg no, cov cuab yeej siv induction hardening niaj hnub tau npaj rau ntawm cov kab ntau lawm lossis kab tsis siv neeg.

5. Kev kho cua sov kom huv. Lub quenching kua siv nyob rau hauv induction quenching feem ntau yog dej los yog aqueous tov nrog additives. Thaum lub sij hawm quenching, yuav luag tsis muaj roj fume thiab qhov chaw ua haujlwm zoo.

6. Nws yooj yim rau kev siv tshuab thiab automation, thiab cov khoom tsim tawm induction hardened feem ntau yog nruab nrog cov cuab yeej sib xws, xws li CNC hardening tshuab cuab yeej, manipulators, thiab lwm yam.