- 16

- Sep

Distribisyon kontinyèl tundish fonn asye ekipman chofaj endiksyon

Continuous casting tundish molten steel ekipman chofaj endiksyon

NT BECA

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Ekipman chofaj endiksyon Tundish gen karakteristik sa yo:

(1) Vitès chofaj rapid ak efikasite chofaj elektrik segondè;

(2) Gen kèk kalite tou ki gen yon sèten efè vibran elektwomayetik, ki se fezab nan retire enklizyon an;

(3) Tanperati pwosesis la fasil pou kontwole, e bagay ki pi enpòtan an se kontwole sipèchofe an asye fonn ak plis presizyon;

(4) Pouvwa chofaj la limite pa pwofondè nivo likid tundish la. Se sèlman lè asye a fonn nan tundish la akimile nan yon pwofondè sèten, chofaj la ka kontinye san pwoblèm.

Gen plizyè kalite ekipman chofaj endiksyon tundish:

(1) Dapre kalite endiktè a, li ka divize an ekipman chofaj endiksyon coreless ak ekipman chofaj endiksyon core;

(2) Dapre estrikti endiktè a, li ka divize an kalite fay ogmante ak kalite tinèl (groove, tranche fonn) ekipman chofaj endiksyon;

(3) Dapre pati chofaj la, li ka divize an chofaj lokal ak chofaj jeneral.

2 Distribisyon kontinyèl tundish fonn asye elektwomayetik aparèy chofaj endiksyon aparèy chofaj

2. 1 Tundish elektwomayetik endiksyon chofaj ekipman matche ak orizontal machin depoze kontinyèl

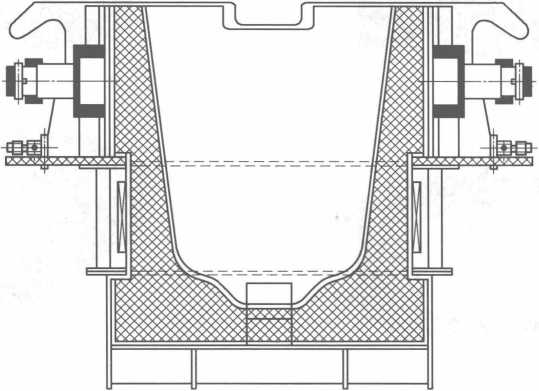

Ekipman chofaj endiksyon elektwomayetik tundish matche ak machin orizontal kontinyèl Distribisyon an montre nan Figi 10-7.

Pwosesis pwodiksyon yon plant asye pur kounye a eksplike.

Figi 10-7 Tundish elektwomayetik endiksyon chofaj ekipman matche ak orizontal machin depoze kontinyèl

Apre tout kalite asye pur yo pakèt, yo chaje nan twa founo endiksyon 5t soti nan tank la manje ak trepye. Apre yo fin asye bouyon an fonn nan tanperati ki nesesè yo (apeprè 1650 ° C), se asye a fonn nan gwo fou a endiksyon vide nan louch la, ak Lè sa a, itilize Kamyon an vide asye a fonn nan gwo founo dife a 8t AOD, kote li sibi dekarburizasyon, salop, defosforizasyon ak retire souf, ak ajisteman nan konpozisyon alyaj la (sitou Cr, Ni), ak Lè sa a, asye a fonn (konpozisyon an ak tanperati satisfè kondisyon yo) Mete asye a fonn nan louch la nan louch la epi sèvi ak teknik la vide. asye a fonn nan louch la nan louch la nan ekipman an chofaj endiksyon elektwomayetik 8t. Se likid la asye pur chofe pa prezèvasyon chalè trase ak jete nan yon ba wonn pa yon machin orizontal kontinyèl Distribisyon epi finalman pouse nan kabann lan refwadisman pa fòme ak taye. .

Apre tout kalite asye pur yo pakèt, yo chaje nan twa founo endiksyon 5t soti nan tank la manje ak trepye. Apre yo fin asye bouyon an fonn nan tanperati ki nesesè yo (apeprè 1650 ° C), se asye a fonn nan gwo fou a endiksyon vide nan louch la, ak Lè sa a, itilize Kamyon an vide asye a fonn nan gwo founo dife a 8t AOD, kote li sibi dekarburizasyon, salop, defosforizasyon ak retire souf, ak ajisteman nan konpozisyon alyaj la (sitou Cr, Ni), ak Lè sa a, asye a fonn (konpozisyon an ak tanperati satisfè kondisyon yo) Mete asye a fonn nan louch la nan louch la epi sèvi ak teknik la vide. asye a fonn nan louch la nan louch la nan ekipman an chofaj endiksyon elektwomayetik 8t. Se likid la asye pur chofe pa prezèvasyon chalè trase ak jete nan yon ba wonn pa yon machin orizontal kontinyèl Distribisyon epi finalman pouse nan kabann lan refwadisman pa fòme ak taye. .

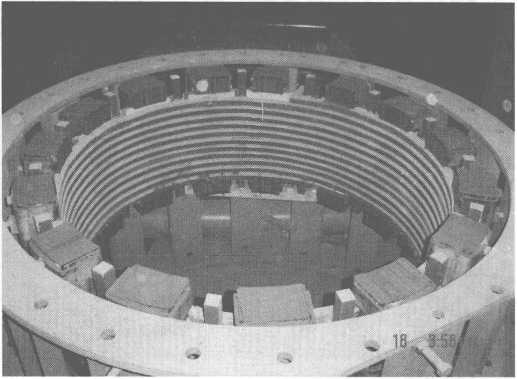

Objè fizik 8t elektwomayetik endiksyon ekipman chofaj louch la montre nan Figi 10-8.

Ekipman chofaj endiksyon elektwomayetik 8t ak 14t tundish, ekipman chofaj endiksyon tundish ka kontwole tanperati a nan asye fonn ak presizyon (ranje erè a se sèlman ±5 ~ 6℃), kidonk asire bon jan kalite a nan billet la. Anplis de sa, tan an ajisteman tanperati nan tundish la kapab tou pwolonje yon fason ki apwopriye, ki montre efè a bon nan ekipman chofaj endiksyon.

2. 2 aparèy Tundish nan ekipman chofaj endiksyon nan machin arc kontinyèl Distribisyon

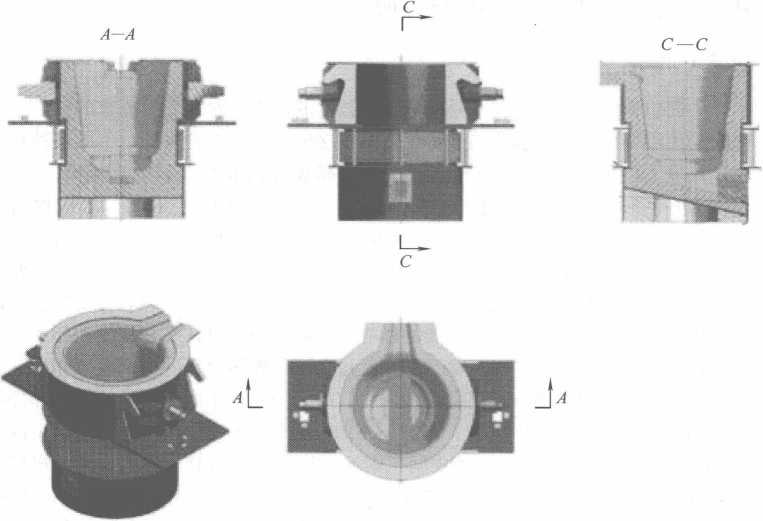

Aparèy tundish nan ekipman chofaj endiksyon nan machin nan Distribisyon kontinyèl arc yo montre nan Figi 10-9.

Apre ark billet kontinyèl Caster la adopte aparèy chofaj elektwomayetik endiksyon aparèy chofaj, tanperati a tapping ka bese (pou egzanp, li kapab

Figi 10-9 aparèy Tundish nan ekipman chofaj endiksyon nan machin arc kontinyèl Distribisyon

Soti nan 1700 ° C a 1650 ° C), sa a pa sèlman ede amelyore lavi sa a ki nan asye pawa founo (konvètisè, founo elektrik arc oswa gwo founo endiksyon), men tou, estabilize tanperati a nan asye fonn nan Distribisyon kontinyèl ak garanti bon jan kalite a nan kontinyèl. Distribisyon billets.

Ki baze sou entwodiksyon ki pi wo a, li ka konsidere ke ekipman chofaj endiksyon mayetik kontinyèl Distribisyon tundish se yon nouvo teknoloji ekonomize enèji ak zanmitay anviwònman an. Adopsyon aparèy sa a se yon pwojè transfòmasyon teknolojik relativman ideyal pou antrepwiz métallurgique, epi li merite pwomosyon ak itilizasyon.

Figi 10-10 montre ekipman chofaj endiksyon elektwomayetik tundish 16t.

Figi 10-10 16t tundish elektwomayetik endiksyon ekipman chofaj

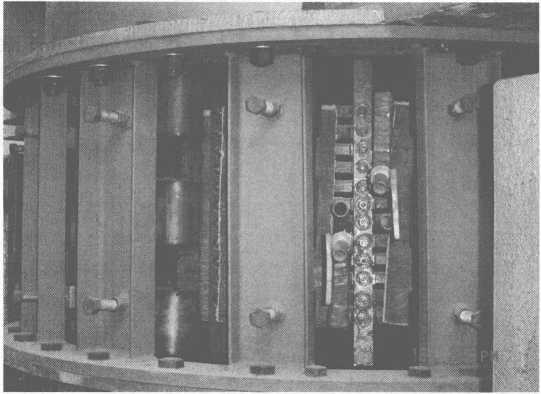

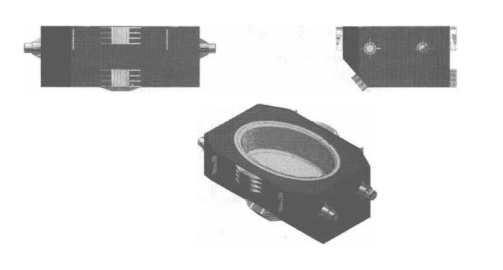

Figi 10-11 se yon dyagram chema nan tundish ekipman chofaj endiksyon 14t.

Figi 10-11 Dyagram chema nan tundish ekipman chofaj endiksyon 14t