- 16

- Sep

Ngokuqhubekayo ukugalela tundish otyhidiweyo izixhobo zokufudumeza induction

Continuous casting tundish molten steel izixhobo zokufudumeza

1 Amagqabantshintshi

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Isixhobo sokufudumeza iTundish sinezi mpawu zilandelayo:

(1) Isantya sokufudumeza ngokukhawuleza kunye nokusebenza kakuhle kokufudumeza kombane;

(2) Ezinye iintlobo zikwanazo nefuthe elithile lombane elishukumisayo, elinceda ukususwa kwezinto ezibandakanyiweyo;

(3) Ubushushu benkqubo bulula ukulawula, kwaye eyona nto ibalulekileyo kukulawula ngokuchanekileyo ngakumbi ukushisa okukhulu kwentsimbi etyhidiweyo;

(4) Amandla okufudumeza anqunyelwe ngobunzulu bomgangatho wolwelo we-tundish. Kuphela xa intsimbi etyhidiweyo kwi-tundish iqokelela kubunzulu obuthile, ukufudumeza kunokuhamba kakuhle.

Kukho iintlobo ezininzi zezixhobo zokufudumeza ze-tundish:

(1) Ngokohlobo lwe-inductor, lunokwahlulwa lube yi-coreless induction heat equipment kunye ne-cored induction heat equipment;

(2) Ngokwesakhiwo se-inductor, inokwahlulwa ibe luhlobo olwandisiweyo lwempazamo kunye nohlobo lwetonela (i-groove, umsele otyhidiweyo) izixhobo zokufudumeza;

(3) Ngokwenxalenye yokufudumeza, inokwahlulwa ibe yindawo yokufudumala yendawo kunye nokufudumeza ngokubanzi.

2 Ngokuqhubekayo ukuphosa i-tundish yensimbi etyhidiweyo ye-electromagnetic induction isixhobo sokufudumeza isixhobo

2. 1 Isixhobo sokufudumeza se-electromagnetic induction ye-Tundish ehambelana nomatshini wokuphosa othe tye oqhubekayo

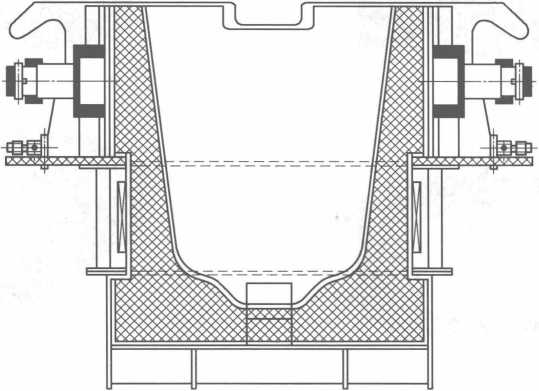

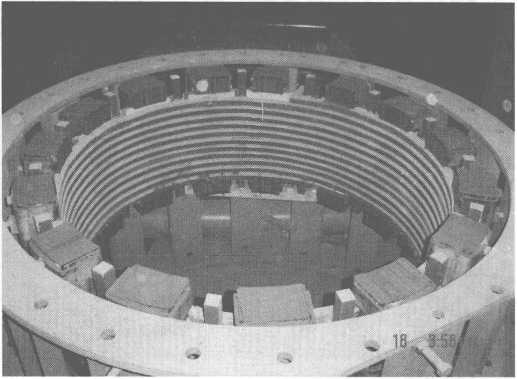

Isixhobo sokufudumala se-electromagnetic induction ye-tundish ehambelana nomatshini wokuphosa othe tye oqhubekayo uboniswe kuMfanekiso 10-7.

Inkqubo yokuvelisa isityalo sensimbi engenasici ichazwa ngoku.

Umzobo 10-7 I-Tundish yezixhobo zokufudumeza ze-electromagnetic ezihambelana nomatshini wokuphosa othe tye oqhubekayo.

Emva kokuba zonke iintlobo zensimbi engenasici zidibene, zilayishwa kwii-furnaces ezintathu ze-5t zokungeniswa kwi-tank yokutya kunye neekrane. Emva kokuba insimbi ye-scrap inyibilika kwiqondo lokushisa elifunekayo (malunga ne-1650 ° C), insimbi etyhidiweyo kwisithando somlilo sokungeniswa igalelwe kwi-ladle, ize isetyenziswe Iloli ithululela insimbi etyhidiweyo kwisithando somlilo se-8t AOD, apho idlula khona i-decarburization, i-slagging, i-dephosphorization kunye nokususwa kwesulfure, kunye nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), kunye nentsimbi etyhidiweyo (ukubunjwa kunye nobushushu buhlangabezana neemfuno) Faka intsimbi etyhidiweyo kwi-ladle kwi-ladle kwaye usebenzise i-crane ukugalela. intsimbi etyhidiweyo kwileyidi kwileyidi ye-8t yesixhobo sokufudumeza sombane sombane. Ulwelo lwensimbi engenasici lufudunyezwa kukugcinwa kobushushu lutsalwa kwaye luphoswe kwibha engqukuva ngomatshini wokuphosa othe tye oqhubekayo kwaye ekugqibeleni utyhalelwe kumandlalo wokupholisa ngokwenza kunye nokucheba. .

Emva kokuba zonke iintlobo zensimbi engenasici zidibene, zilayishwa kwii-furnaces ezintathu ze-5t zokungeniswa kwi-tank yokutya kunye neekrane. Emva kokuba insimbi ye-scrap inyibilika kwiqondo lokushisa elifunekayo (malunga ne-1650 ° C), insimbi etyhidiweyo kwisithando somlilo sokungeniswa igalelwe kwi-ladle, ize isetyenziswe Iloli ithululela insimbi etyhidiweyo kwisithando somlilo se-8t AOD, apho idlula khona i-decarburization, i-slagging, i-dephosphorization kunye nokususwa kwesulfure, kunye nokulungiswa kokwakheka kwe-alloy (ikakhulukazi i-Cr, i-Ni), kunye nentsimbi etyhidiweyo (ukubunjwa kunye nobushushu buhlangabezana neemfuno) Faka intsimbi etyhidiweyo kwi-ladle kwi-ladle kwaye usebenzise i-crane ukugalela. intsimbi etyhidiweyo kwileyidi kwileyidi ye-8t yesixhobo sokufudumeza sombane sombane. Ulwelo lwensimbi engenasici lufudunyezwa kukugcinwa kobushushu lutsalwa kwaye luphoswe kwibha engqukuva ngomatshini wokuphosa othe tye oqhubekayo kwaye ekugqibeleni utyhalelwe kumandlalo wokupholisa ngokwenza kunye nokucheba. .

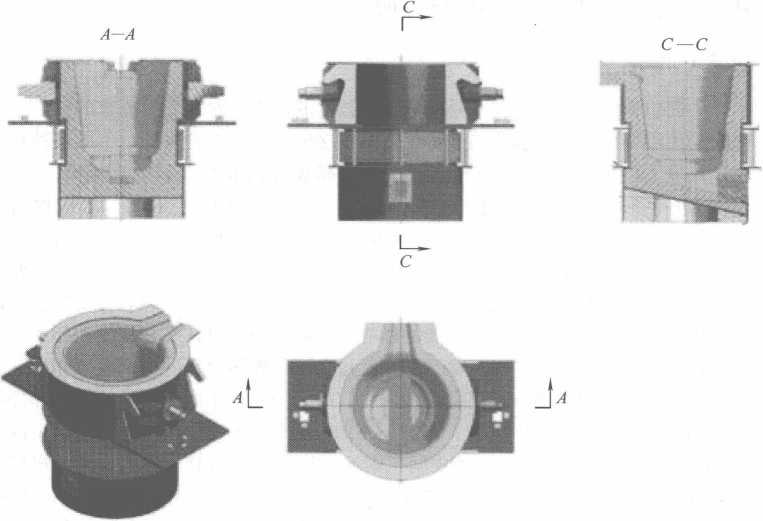

Into ebonakalayo ye-8t ye-electromagnetic induction yesixhobo sokufudumeza iboniswe kuMfanekiso 10-8.

I-8t kunye ne-14t tundish izixhobo zokufudumeza i-electromagnetic induction, izixhobo zokufudumeza ze-tundish zingakwazi ukulawula ngokungqongqo kunye ngokuchanekileyo ubushushu bentsimbi etyhidiweyo (uluhlu lwephutha luyi-± 5 ~ 6 ℃ kuphela), ngaloo ndlela luqinisekisa umgangatho we-billet. Ukongezelela, ixesha lokulungiswa kweqondo lokushisa le-tundish lingakwandiswa ngokufanelekileyo, libonisa umphumo omhle wezixhobo zokufudumeza induction.

2. 2 Isixhobo se-Tundish sezixhobo zokufudumeza zokungeniswa kwe-arc umatshini oqhubekayo wokuphosa

Isixhobo se-tundish sesixhobo sokufudumeza i-induction ye-arc umatshini oqhubekayo wokuphosa uboniswe kuMfanekiso 10-9.

Emva kokuba i-arc billet eqhubekayo i-caster ithatha isixhobo sokufudumeza sokufakelwa kwe-electromagnetic, iqondo lobushushu lokucofa linokwehliswa (umzekelo, linokuba

Umzobo 10-9 Isixhobo se-Tundish sezixhobo zokufudumeza zokungeniswa kwe-arc umatshini oqhubekayo wokuphosa

Ukususela kwi-1700 ° C ukuya kwi-1650 ° C), oku akuncedi nje ukuphucula ubomi bentsimbi yokwenza isithando somlilo (isiguquli, isithando sombane se-arc okanye isithando somlilo), kodwa kwakhona kuzinzisa ubushushu bentsimbi etyhidiweyo ekubunjweni okuqhubekayo kwaye iqinisekisa umgangatho oqhubekayo. ukuphosa iibhilidi.

Ngokusekelwe kwintshayelelo engentla, kunokuqwalaselwa ukuba i-tundish eqhubekayo yokufaka izixhobo zokufudumeza i-magnetic induction iteknoloji entsha yokugcina amandla kunye ne-teknoloji ehambelana nokusingqongileyo. Ukwamkelwa kwesi sixhobo yiprojekthi yenguqu yetekhnoloji efanelekileyo kumashishini esinyithi, kwaye kufanelekile ukukhuthazwa kunye nokusetyenziswa.

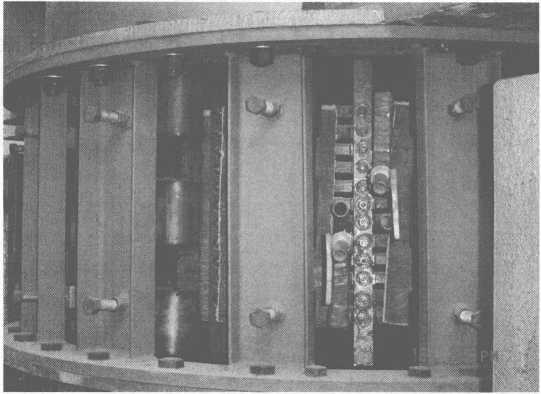

Umzobo we-10-10 ubonisa izixhobo zokufudumeza ze-electromagnetic induction ze-16t.

Umzobo 10-10 16t tundish i-electromagnetic induction zokufudumeza izixhobo

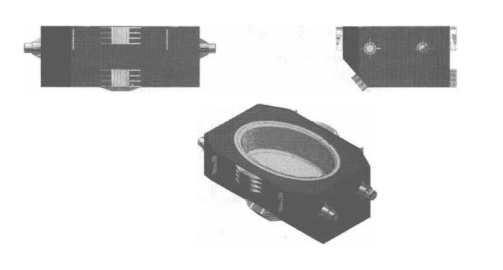

Umzobo we-10-11 ngumzobo oqingqiweyo we-tundish ye-14t izixhobo zokufudumeza induction.

Umzobo we-10-11 umzobo weSchematic we-tundish ye-14t izixhobo zokufudumeza