- 16

- Sep

Casting terus-terusan tundish molten steel peralatan pemanas induksi

Continuous casting tundish molten steel peralatan pemanasan induksi

1 Ringkesan

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Peralatan pemanas induksi Tundish nduweni karakteristik ing ngisor iki:

(1) Kacepetan pemanasan cepet lan efisiensi pemanasan listrik sing dhuwur;

(2) Sawetara jinis uga duwe efek aduk elektromagnetik tartamtu, sing kondusif kanggo mbusak inklusi;

(3) Suhu proses gampang dikontrol, lan sing paling penting yaiku ngontrol superheat baja molten kanthi luwih akurat;

(4) Daya pemanasan diwatesi dening ambane tingkat cairan tundish. Mung nalika baja molten ing tundish accumulates menyang ambane tartamtu, dadi panas bisa nerusake lancar.

Ana sawetara jinis peralatan pemanas induksi tundish:

(1) Miturut jinis induktor, bisa dipérang dadi peralatan pemanasan induksi inti lan peralatan pemanasan induksi inti;

(2) Miturut struktur induktor, bisa dipérang dadi jinis fault tambah lan jinis trowongan (alur, molten trench) peralatan pemanasan induksi;

(3) Miturut bagean dadi panas, bisa dipérang dadi panas lokal lan panas sakabèhé.

2 Casting terus-terusan tundish baja molten piranti peralatan pemanasan induksi elektromagnetik

2. 1 peralatan pemanas induksi elektromagnetik Tundish dicocogake karo mesin casting terus horisontal

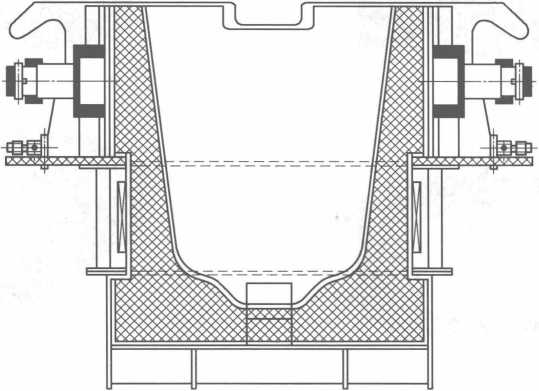

Peralatan pemanasan induksi elektromagnetik tundish sing cocog karo mesin casting terus horisontal ditampilake ing Gambar 10-7.

Proses produksi pabrik stainless steel saiki diterangake.

Gambar 10-7 Peralatan pemanas induksi elektromagnetik Tundish sing cocog karo mesin casting terus-terusan horisontal

Sawise kabeh jinis stainless steel wis batched, lagi dimuat menyang telung tungku induksi 5t saka tank dipakani karo crane. Sawise baja kethokan dilebur ing suhu sing dibutuhake (kira-kira 1650 ° C), baja molten ing tungku induksi diwutahake menyang ladle, lan banjur digunakake Truk pour baja molten menyang tungku 8t AOD, ing ngendi dheweke ngalami dekarburisasi, slagging, dephosphorization lan belerang aman, lan imbuhan saka komposisi alloy (utamané Cr, Ni), lan banjur baja molten (komposisi lan suhu ketemu syarat) Sijine baja molten ing ladle menyang ladle lan nggunakake crane kanggo pour baja molten ing ladle menyang ladle saka peralatan pemanasan induksi elektromagnetik 8t. Cairan stainless steel digawe panas dening pengawetan panas digambar lan casted menyang bar babak dening horisontal terus mesin casting lan pungkasanipun di-push menyang amben cooling dening mbentuk lan shearing. .

Sawise kabeh jinis stainless steel wis batched, lagi dimuat menyang telung tungku induksi 5t saka tank dipakani karo crane. Sawise baja kethokan dilebur ing suhu sing dibutuhake (kira-kira 1650 ° C), baja molten ing tungku induksi diwutahake menyang ladle, lan banjur digunakake Truk pour baja molten menyang tungku 8t AOD, ing ngendi dheweke ngalami dekarburisasi, slagging, dephosphorization lan belerang aman, lan imbuhan saka komposisi alloy (utamané Cr, Ni), lan banjur baja molten (komposisi lan suhu ketemu syarat) Sijine baja molten ing ladle menyang ladle lan nggunakake crane kanggo pour baja molten ing ladle menyang ladle saka peralatan pemanasan induksi elektromagnetik 8t. Cairan stainless steel digawe panas dening pengawetan panas digambar lan casted menyang bar babak dening horisontal terus mesin casting lan pungkasanipun di-push menyang amben cooling dening mbentuk lan shearing. .

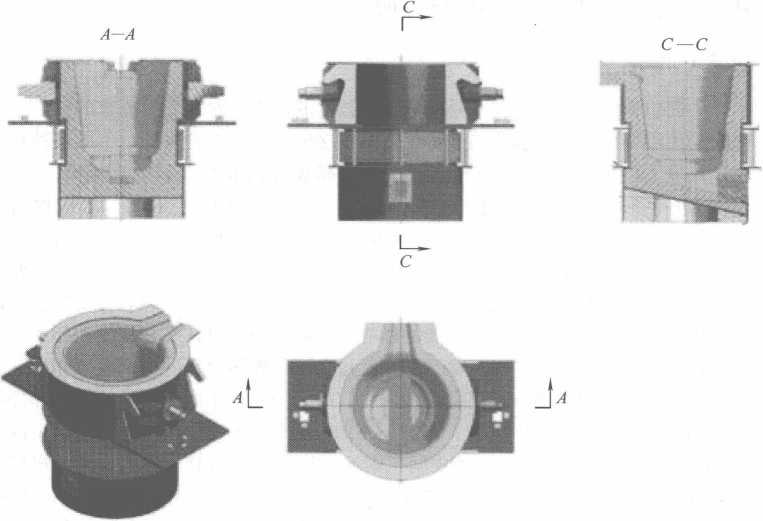

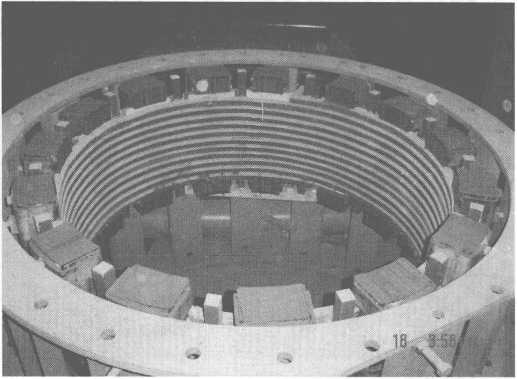

Objek fisik saka ladle peralatan pemanasan induksi elektromagnetik 8t ditampilake ing Figure 10-8.

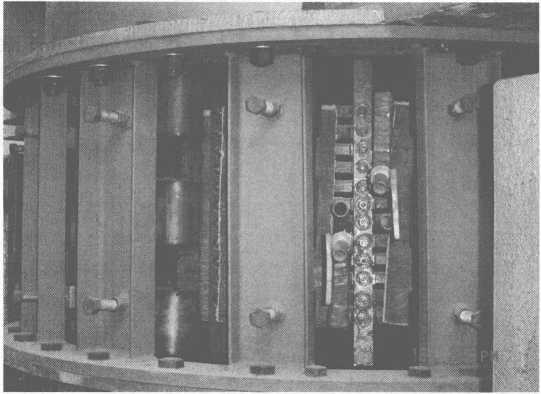

8t lan 14t peralatan pemanas induksi elektromagnetik tundish, peralatan pemanas induksi tundish bisa ngontrol suhu baja molten kanthi ketat lan akurat (kisaran kesalahan mung ± 5 ~ 6 ℃), saéngga njamin kualitas billet. Kajaba iku, wektu pangaturan suhu tundish uga bisa ditambah kanthi tepat, nuduhake efek apik saka peralatan pemanasan induksi.

2. 2 piranti Tundish peralatan pemanasan induksi saka mesin casting terus-terusan

Piranti tundish saka peralatan pemanasan induksi saka mesin casting terus-terusan ditampilake ing Gambar 10-9.

Sawise busur billet terus caster adopts induksi elektromagnetik peralatan dadi panas tundish, suhu nunyuk bisa sudo (contone, iku bisa

Gambar 10-9 Piranti Tundish saka peralatan pemanasan induksi saka mesin casting terus-terusan

Saka 1700 ° C kanggo 1650 ° C), iki ora mung mbantu kanggo nambah urip steelmaking furnace lining (konverter, tungku busur listrik utawa tungku induksi), nanging uga stabilizes suhu baja molten ing casting terus-terusan lan njamin kualitas terus-terusan. casting billet.

Adhedhasar introduksi ing ndhuwur, bisa dianggep manawa peralatan pemanasan induksi magnetik tundish terus-terusan minangka teknologi hemat energi lan ramah lingkungan. Adopsi piranti iki minangka proyek transformasi teknologi sing cocog kanggo perusahaan metalurgi, lan pantes promosi lan digunakake.

Gambar 10-10 nuduhake peralatan pemanasan induksi elektromagnetik tundish 16t.

Gambar 10-10 16t peralatan pemanas induksi elektromagnetik tundish

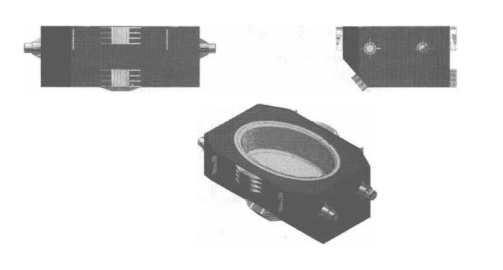

Gambar 10-11 minangka diagram skematik tundish saka peralatan pemanas induksi 14t.

Gambar 10-11 Diagram skematik tundish peralatan pemanas induksi 14t