- 16

- Sep

Uzluksiz quyma tundish eritilgan po’latdan induksion isitish uskunalari

Continuous casting tundish molten steel indüksiyon isitish uskunalari

1 Umumiy nuqtai

Tundish molten steel induction heating equipment technology is developed with the progress of continuous casting technology, the improvement of steel quality requirements, the need for energy saving and consumption reduction, and the matching of external refining and continuous casting processes. Different steel grades have different requirements on the AT of molten steel superheat. For thick plates, in order to reduce internal cracks and loose center, the AT should be low (5~200T); for cold-rolled thin plates, the surface is required to have good quality. Higher (15~300℃). However, the molten steel superheat must be stabilized within a certain range to minimize fluctuations. This is a necessary condition to ensure the smooth progress of continuous casting production, prevent nozzle blockage or prevent leaking accidents, and ensure the quality of cast slabs. The enhancement of the heating function of the tundish makes it possible to control the superheat of molten steel stably. The temperature of the molten steel of different ladle fluctuates, which has an adverse effect on the continuous casting process, and the heating of the tundish can compensate for it to some extent. However, it must be pointed out that maintaining a stable molten steel superheat mainly depends on the proper tapping temperature and the adjustment structure after tapping, and the tundish heating can only play a supplementary role. Nevertheless, the heating and control of molten steel in the tundish is still receiving attention from the metallurgical community. Some countries represented by Japan, the United States, the United Kingdom, and France have successively carried out research on tundish molten steel heating technology from the 1970s to the 1980s. Japan’s Kawasaki Company first developed and obtained a Japanese patent as early as 1982. At present, the tundish molten steel heating technology successfully developed or under development usually adopts the physical heating method. In the physical heating method, electric energy is used as the heat source and converted according to the electric energy. Different mechanisms can be divided into: electromagnetic induction heating equipment, plasma heating, electroslag heating and DC ceramic heating technology.

Tundish induksion isitish uskunalari quyidagi xususiyatlarga ega:

(1) Tez isitish tezligi va yuqori elektr isitish samaradorligi;

(2) Ba’zi turlar, shuningdek, qo’shimchalarni olib tashlash uchun qulay bo’lgan ma’lum bir elektromagnit aralashtirish effektiga ega;

(3) Jarayon haroratini nazorat qilish oson va eng muhimi, eritilgan po’latning qizib ketishini aniqroq nazorat qilishdir;

(4) Isitish quvvati tundish suyuqligi darajasining chuqurligi bilan cheklangan. Faqat tundishdagi eritilgan po’lat ma’lum bir chuqurlikda to’planganda, isitish muammosiz davom etishi mumkin.

Tundish induksion isitish uskunalarining bir nechta turlari mavjud:

(1) Induktor turiga ko’ra, uni yadrosiz indüksiyon isitish uskunasiga va yadroli indüksiyon isitish uskunasiga bo’lish mumkin;

(2) Induktorning tuzilishiga ko’ra, uni kattalashtirilgan nosozlik turiga va tunnel turiga (yiv, eritilgan xandaq) indüksiyon isitish uskunasiga bo’lish mumkin;

(3) Isitish qismiga ko’ra, uni mahalliy isitish va umumiy isitishga bo’lish mumkin.

2 Uzluksiz quyma tundish eritilgan po’lat elektromagnit induksion isitish uskunasi qurilmasi

2. Gorizontal uzluksiz quyma mashinasi bilan mos keladigan 1 Tundish elektromagnit induksion isitish uskunasi

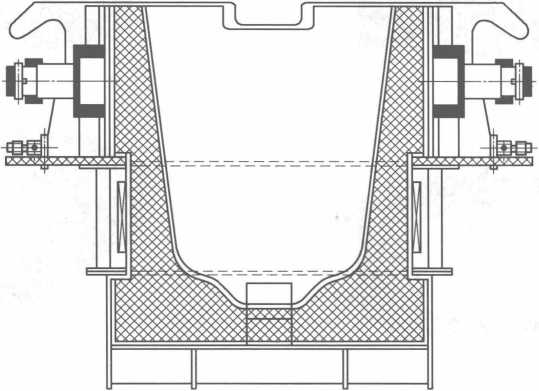

Gorizontal uzluksiz quyish mashinasi bilan mos keladigan tundish elektromagnit induksion isitish uskunasi 10-7-rasmda ko’rsatilgan.

Endi zanglamaydigan po’latdan yasalgan zavodning ishlab chiqarish jarayoni tushuntiriladi.

Shakl 10-7 Gorizontal uzluksiz quyish mashinasi bilan mos keladigan Tundish elektromagnit induksion isitish uskunasi

Barcha turdagi zanglamaydigan po’latdan ishlab chiqarilgandan so’ng, ular kranlar bilan oziqlantiruvchi idishdan uchta 5t indüksiyon pechlariga yuklanadi. Po’lat qoldiqlari kerakli haroratgacha (taxminan 1650 ° C) eritilgandan so’ng, indüksiyon pechidagi eritilgan po’lat cho’chqaga quyiladi va keyin ishlatiladi Yuk mashinasi eritilgan po’latni 8t AOD pechiga quyadi, u erda dekarburizatsiyadan o’tadi, cüruflash, fosforsizlantirish va oltingugurtni olib tashlash va qotishma tarkibini sozlash (asosan Cr, Ni), so’ngra eritilgan po’lat (tarkibi va harorati talablarga javob beradi) Eritilgan po’latni cho’chqaga soling va quyish uchun krandan foydalaning. 8t elektromagnit induksiyali isitish uskunasining cho’chqasiga cho’chqadagi eritilgan po’lat. Issiqlikni saqlash yo’li bilan isitiladigan zanglamaydigan po’latdan suyuqlik tortiladi va gorizontal uzluksiz quyish mashinasi tomonidan dumaloq barga quyiladi va nihoyat shakllantirish va kesish orqali sovutish to’shagiga suriladi. .

Barcha turdagi zanglamaydigan po’latdan ishlab chiqarilgandan so’ng, ular kranlar bilan oziqlantiruvchi idishdan uchta 5t indüksiyon pechlariga yuklanadi. Po’lat qoldiqlari kerakli haroratgacha (taxminan 1650 ° C) eritilgandan so’ng, indüksiyon pechidagi eritilgan po’lat cho’chqaga quyiladi va keyin ishlatiladi Yuk mashinasi eritilgan po’latni 8t AOD pechiga quyadi, u erda dekarburizatsiyadan o’tadi, cüruflash, fosforsizlantirish va oltingugurtni olib tashlash va qotishma tarkibini sozlash (asosan Cr, Ni), so’ngra eritilgan po’lat (tarkibi va harorati talablarga javob beradi) Eritilgan po’latni cho’chqaga soling va quyish uchun krandan foydalaning. 8t elektromagnit induksiyali isitish uskunasining cho’chqasiga cho’chqadagi eritilgan po’lat. Issiqlikni saqlash yo’li bilan isitiladigan zanglamaydigan po’latdan suyuqlik tortiladi va gorizontal uzluksiz quyish mashinasi tomonidan dumaloq barga quyiladi va nihoyat shakllantirish va kesish orqali sovutish to’shagiga suriladi. .

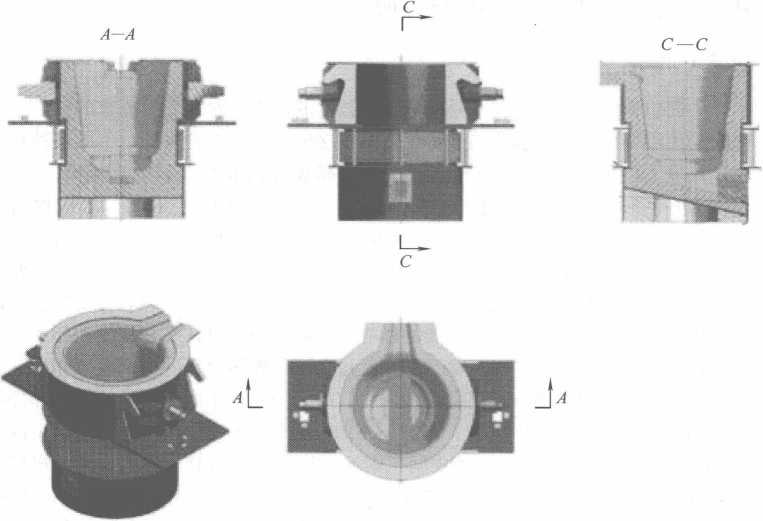

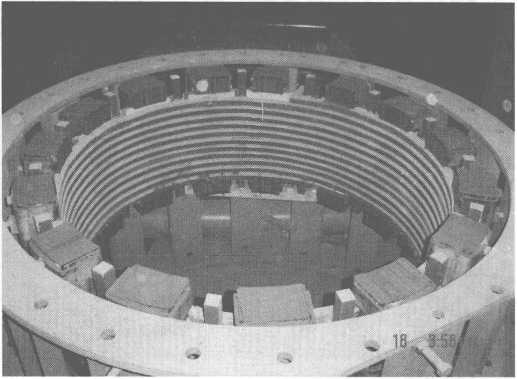

8t elektromagnit induksion isitish uskunasining fizik ob’ekti 10-8-rasmda ko’rsatilgan.

8t va 14t tundish elektromagnit induksion isitish uskunalari, tundish indüksiyon isitish uskunalari eritilgan po’latning haroratini qat’iy va aniq nazorat qilishi mumkin (xato diapazoni faqat ± 5 ~ 6 ℃), shu bilan igna sifatini ta’minlaydi. Bundan tashqari, tundishning haroratni sozlash vaqti ham mos ravishda uzaytirilishi mumkin, bu esa indüksiyon isitish uskunasining yaxshi ta’sirini ko’rsatadi.

2. Ark uzluksiz quyish mashinasining induksion isitish uskunasining 2 tundish qurilmasi

Ark uzluksiz quyish mashinasining induksion isitish uskunasining tundish qurilmasi 10-9-rasmda ko’rsatilgan.

Ark ignabargli uzluksiz g’ildirak elektromagnit induksion isitish moslamasini qabul qilgandan so’ng, teginish harorati tushirilishi mumkin (masalan, u bo’lishi mumkin).

Shakl 10-9 Ark uzluksiz quyish mashinasining induksion isitish uskunasining tundish qurilmasi

1700 ° C dan 1650 ° C gacha), bu nafaqat po’lat ishlab chiqaruvchi pechning (konvertor, elektr boshq o’chog’i yoki indüksiyon pechining) ishlash muddatini yaxshilashga yordam beradi, balki uzluksiz quyishda eritilgan po’latning haroratini barqarorlashtiradi va uzluksiz ishlov berish sifatini kafolatlaydi. quyish ignalari.

Yuqoridagi muqaddima asosida, uzluksiz quyma tundish magnit-induksion isitish uskunasi energiyani tejovchi va ekologik toza texnologiya deb hisoblash mumkin. Ushbu qurilmaning qabul qilinishi metallurgiya korxonalari uchun nisbatan ideal texnologik transformatsiya loyihasi bo’lib, uni ilgari surish va ishlatishga loyiqdir.

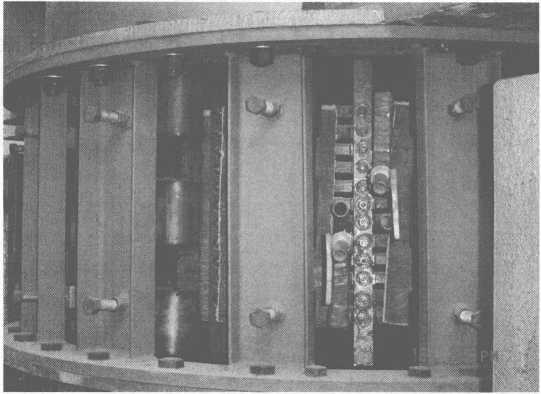

10-10-rasmda 16t tundish elektromagnit induksion isitish uskunasi ko’rsatilgan.

Shakl 10-10 16t tundish elektromagnit induksion isitish uskunalari

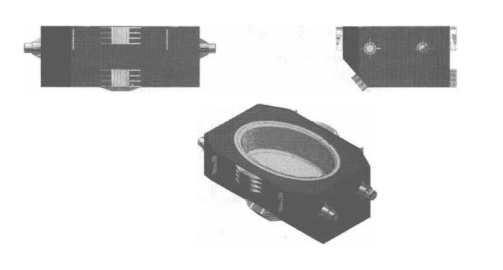

10-11-rasmda 14t induksion isitish uskunasining tundish sxemasi keltirilgan.

10-11-rasm 14t induksion isitish uskunasi tundishining sxematik diagrammasi