- 18

- Oct

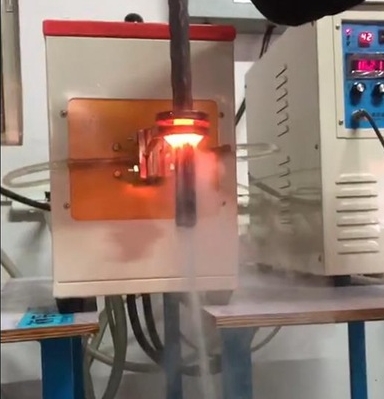

Kwatanta shigar da dumama mai zafi da zafin wutar makera

Kwatanta shigar da dumama mai zafi da zafin wutar makera

Idan aka kwatanta da zafin jiki a cikin tanderu, ƙarar zafi mai zafi yana da fa’idodi masu zuwa:

1) Lokacin dumama ya takaice kuma yawan aiki ya yi yawa. Haɓaka yawan zafin jiki na shigar da ƙaramin zafin zafin jiki shine 4-20T/s, ƙimar zazzabi na matsakaici da matsanancin zafin jiki shine 5-30Y/s, layin silinda yana amfani da zafin mitar ƙarfin, guda 3 a lokaci guda, da zafin Lokacin 220Y shine 30-40s.

2) Za a iya samun kwanciyar hankali da ingantattun kaddarorin inji.

Wani ya gudanar da gwaje -gwaje ƙwaƙwalwar shiga, induction dumama da zafin jiki (IH), dumama wutar makera da zazzabi (FH) na sandunan ƙarfe na PC. Ana nuna sigogin fasaha na ƙayyadaddun maganin zafi biyu a cikin tebur.

Nau’i biyu na ƙayyadaddun maganin zafi sigogi na fasaha

| Samfurin hanyar dumama | Quenching dumama

Zazzabi/T |

Quenching taurin

HRC |

Zafin zafin jiki

/T |

Rawan zafi

/(R/s) |

Quenching dumama

Lokaci/s |

Lokacin jinkiri

/s |

ma’aunin zafi da sanyio |

| IH | 1020 | 35 ~ 55 | 300 -750 | 50 | 50 | 43 | Rikicin ma’aunin zafi da sanyio |

| FH | 920 | 35-55 | 250-600 | 1 | 7200 | 10800 | CA thermocouple |

Sakamakon gwajin biyu ya nuna cewa:

1) A cikin hanyoyin dumama biyu, taurin samfurin sandar karfe yana raguwa a layi tare da haɓaka zafin zafin.

2) Domin samun maƙarƙashiya iri ɗaya, zafin zafin IH shine 100-130 ℃ sama da na FH. Wannan banbancin na iya cika gaɓoɓin da ɗan gajeren lokacin dumamar IH ya haifar.

3) Yin amfani da nazarin rarrabuwar X-ray, ɗimbin ɗimbin ɗimbin austenite da aka auna ta babban ƙarfin shigar da dumama da samfuran dumama murhu sun kasance 4.3% da 3%, bi da bi, kuma sannu a hankali ya ragu tare da karuwar zafin zafin; amma don A daidai zafin zafin jiki, abin da aka riƙe austenite na samfurin IH ya fi na FH. A 400 ° C tempering zafin jiki, taro taro na riƙe austenite a FH ne kasa da 1%, yayin da tsohon ne 2.7%. Lokacin da zazzabi mai zafi ya yi ƙasa da 600 ℃, ƙimar taro na austenite da aka riƙe ba zai yi ƙasa da 1%ba. Bambanci a cikin wannan tsarin zafin jiki saboda hanyoyin dumama daban -daban shima yana ɗaya daga cikin halayen shigar da zafi.

4) Dangantaka tsakanin hanyar maganin zafi da kaddarorin inji. Don kwatanta kaddarorin inji na samfuran IH da FH, an taƙaita alaƙar da ke tsakanin ƙarfi, filastik, tauri da taurin da aka samu a gwaje -gwajen injinan daban -daban, kuma sakamakon haka kamar haka:

Ƙarfin ƙarfi, ƙarfin ƙarfi da ƙarfin ƙarfi duk suna ƙaruwa tare da haɓaka taurin (bambancin tsakanin IH da FH ba babba bane). Bugu da ƙari, koda tsarin damuwar kaya ya bambanta, raunin ƙarfi da ƙarfi zuwa ƙarfin ƙarfi yana bambanta kusan a cikin kewayon 0.6 zuwa 0.7, don haka banbanci a cikin yanayin canje -canjen ƙarfi daban -daban shima ƙarami ne.

A kowane taurin, filastik da taurin samfurin IH sun fi na samfurin FH. Amfani da IH don haɓaka rabo na filastik, elongation bayan karaya shine 10%, raguwar yanki shine 30%, kuma wasu sun kai 70%. Saboda haka, idan aka kwatanta da samfurin FH, samfurin IH yana da hatsi masu kyau da kyakkyawan ƙarfi da tauri. Bayan tsananin zafin zafin jiki, samfurin ya ƙunshi ƙarin austenite da aka riƙe, wanda zai iya inganta filastik da taurin ƙarfe. ; Lokacin da taurin biyu iri ɗaya ne, IH yana da sauri da ɗan gajeren lokacin dumama, don haka zafin zafin sa ya fi FH.

A takaice, wasan kwaikwayon samfurin da IH ya bi ya fi na samfurin FH. Ya kamata a lura cewa saboda saurin sauri da ɗan gajeren lokacin shigar da zafi, zafin zafin yana da girma fiye da zafin zafi a cikin tanderun da 100-130 ° C. Idan aka kwatanta da zafin jiki a cikin tanderu, zafin kai yana ƙara yawan zafin jiki sosai.