- 18

- Oct

Comparison of induction heating tempering and furnace tempering

Comparison of induction heating tempering and furnace tempering

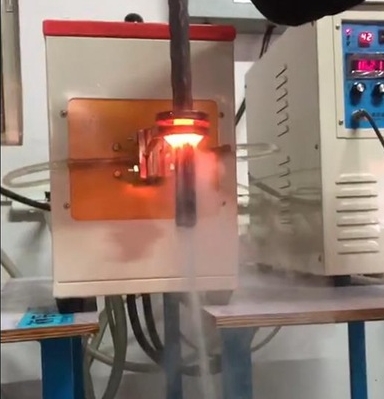

Compared with tempering in furnace, induction heating tempering has the following advantages:

1 ) The heating time is short and the productivity is high. The temperature rise rate of induction low temperature tempering is 4-20T/s, the temperature rise rate of medium and high temperature tempering is 5-30Y/s, the cylinder liner uses power frequency tempering, 3 pieces at a time, and the tempering time of 220Y is 30-40s.

2 ) Stable and better mechanical properties can be obtained.

Someone has conducted experiments on indukčné tvrdnutie, induction heating and tempering (IH), furnace heating and tempering (FH) of PC steel bars. The technical parameters of the two heat treatment specifications are shown in the table.

Two kinds of heat treatment specification technical parameters

| Sample heating method | Quenching heating

Temperature/T |

Tvrdosť kalenia

HRC |

Teplota popúšťania

/T |

Rýchlosť ohrevu

/(R/s) |

Quenching heating

Time/s |

Tempering time

/s |

Teplomer |

| IH | 1020 | 35 ~ 55 | 300-750 | 50 | 50 | 43 | Radiation thermometer |

| FH | 920 | 35-55 | 250-600 | 1 | 7200 | 10800 | CA thermocouple |

The two test results show that:

1 ) In the two heating methods, the hardness of the steel bar sample decreases linearly with the increase of the tempering temperature.

2 ) In order to obtain the same tempering hardness, the tempering temperature of IH is 100-130℃ higher than that of FH. This difference can make up for the shortcomings caused by the short IH heating time.

3 ) Using X-ray diffraction analysis, the mass fractions of retained austenite measured by high-frequency induction heating and general furnace heating samples were 4.3% and 3%, respectively, and gradually decreased with the increase of tempering temperature; but for At the same tempering temperature, the retained austenite content of the IH sample is higher than that of the FH. At 400°C tempering temperature, the mass fraction of retained austenite in FH is less than 1%, while the old is 2.7%. When the tempering temperature is lower than 600℃, the mass fraction of retained austenite will not be lower than 1%. The difference in this tempering process due to different heating methods is also one of the characteristics of induction tempering.

4 ) The relationship between heat treatment method and mechanical properties. In order to compare the mechanical properties of IH and FH samples, the relationship between strength, plasticity, toughness and hardness obtained in various mechanical tests was summarized, and the results are as follows:

The tensile strength, yield strength and shear strength all increase with the increase of hardness (the difference between IH and FH is not big). In addition, even if the load stress patterns are different, the ratio of shear strength to tensile strength varies almost in the range of 0.6 to 0.7, so the difference in the trend of various strength changes is also very small.

At any hardness, the plasticity and hardness of the IH sample are higher than those of the FH sample. Using IH to increase the ratio of plasticity, the elongation after fracture is 10%, the reduction of area is 30%, and some are as high as 70%. Therefore, compared with the FH sample, the IH sample has fine grains and excellent strength and toughness. After high temperature tempering, the sample contains more retained austenite, which can improve the plasticity and toughness of the steel. ; When the two hardnesses are the same, IH is fast and short-time heating, so its tempering temperature is higher than FH.

In short, the performance of the IH-treated sample is better than that of the FH sample. It should be noted that due to the rapid and short time of induction tempering, the tempering temperature is relatively higher than the tempering in the furnace by 100-130°C. Compared with tempering in the furnace, self-tempering increases the temperature more significantly.