- 08

- Feb

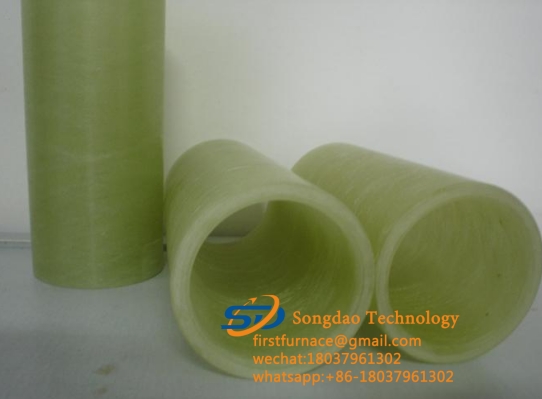

Produksietegnologie en ontwikkeling en toepassing van veselglasbuis

Produksietegnologie en ontwikkeling en toepassing van veselglasbuis

Daar is drie hooftipes glasvesel buis production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Wederkerende filament-wikkelproses (wat aan die vaste-lengte-metode behoort): In hierdie proses beweeg die dooptenk heen en weer met die roterende deur, en die lang veselglasfilamente word teen ‘n sekere skuins hoek met betrekking tot die spil-as en die hulphoek geplaas. (dws. Die wikkelhoek) word beheer deur die verhouding van die bewegende spoed van die dooptenk tot die rotasiespoed van die deurn, en die translasiebeweging van die dooptenk word beheer deur gerekenariseerde elektromeganiese beheer. Die aantal wikkellae word geleidelik vermeerder totdat die ontwerpte wanddikte bereik word. Nadat die wikkeling voltooi is, is die hars in die artikel aansienlik genees. Na genesing word die deurn uit die veselglaspyp verwyder.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.