- 08

- Feb

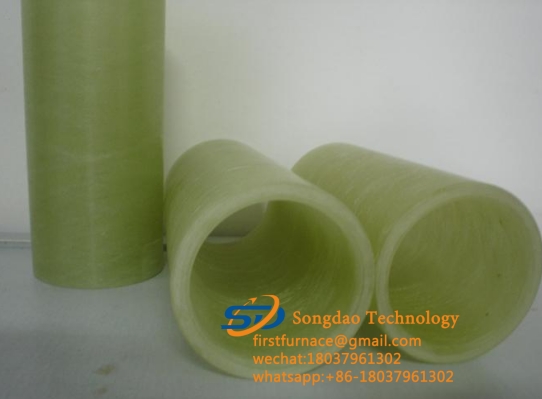

玻璃纖維管的生產技術及開發與應用

玻璃纖維管的生產技術及開發與應用

共有三種主要類型 玻璃纖維管 production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

往復式長絲纏繞工藝(屬於定長法):在此工藝中,浸漬槽隨旋轉的芯軸往復運動,玻璃長絲相對芯軸軸線成一定的斜角放置,輔助角(即捲繞角)由浸漬槽的移動速度與芯軸的轉速之比控制,浸漬槽的平移運動由電腦機電控制。 逐漸增加纏繞層數,直至達到設計壁厚。 纏繞完成後,製品中的樹脂基本固化。 固化後,將心軸從玻璃纖維管上取下。

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.