- 08

- Feb

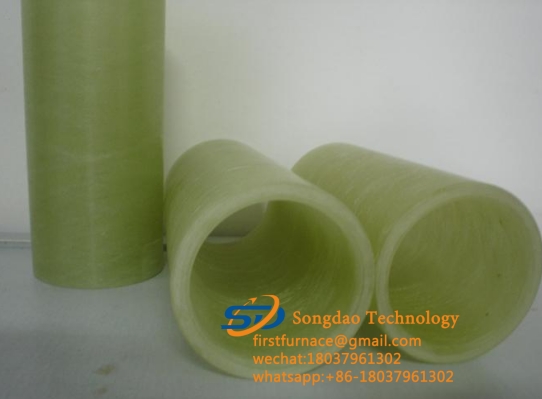

Teknolojia famokarana sy fampandrosoana ary fampiharana ny Tube Fiberglass

Teknolojia famokarana sy fampandrosoana ary fampiharana ny Tube Fiberglass

Misy karazany telo lehibe ny fantsona fibre fitaratra production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Filamenta miolikolika dingana (an’ny fomba raikitra-lavany): Amin’ity dingana ity, ny tanky fandevenana dia mamaly amin’ny mandrel mihodina, ary ny filaments fitaratra fibre lava dia apetraka amin’ny zoro oblique iray mifandraika amin’ny axe mandrel, ary ny zoro fanampiny. (izany hoe. Ny zoro mihodinkodina) dia fehezin’ny tahan’ny hafainganam-pandehan’ny fiara mifono vy amin’ny hafainganam-pandehan’ny mandrel, ary ny hetsiky ny fandikana ny tank dia fehezin’ny fanaraha-maso elektronika elektronika. Ampitomboina tsikelikely ny isan’ny sosona miolikolika mandra-pahatongan’ny hatevin’ny rindrina natao. Rehefa vita ny fanodinana, dia sitrana tanteraka ny resin ao amin’ilay lahatsoratra. Aorian’ny fikarakarana dia esorina amin’ny fantsona fiberglass ny mandrel.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.