- 08

- Feb

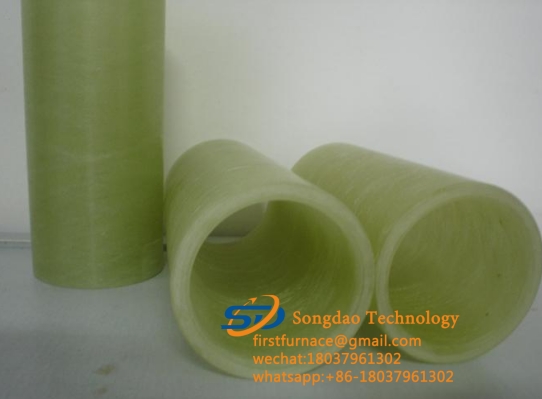

Teknụzụ mmepụta na mmepe na ngwa nke fiberglass Tube

Teknụzụ mmepụta na mmepe na ngwa nke fiberglass Tube

E nwere isi ihe atọ dị iche iche iko eriri tube production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Usoro ntụgharị filament na-emeghachi omume (nke bụ usoro a kapịrị ọnụ): N’ime usoro a, tankị na-atụgharị na-atụgharị na mandrel na-atụgharị, na ogologo fiber glass filaments na-etinye n’otu akụkụ oblique nke metụtara axis mandrel, na akụkụ inyeaka. (ie. Akuku ikuku) na-achịkwa site na oke nke ọsọ na-akpụ akpụ nke tankị ntanye na ọsọ ntụgharị nke mandrel, na mmegharị ntụgharị nke tankị mmiri na-achịkwa site na njikwa eletrọnịkị kọmputa. Ọnụ ọgụgụ nke winding n’ígwé na-eji nwayọọ nwayọọ na-abawanye ruo mgbe a haziri ọkpụrụkpụ mgbidi ruru. Mgbe ikuku gwụchara, resin dị n’ime akụkọ ahụ ga-agwọta nke ukwuu. Mgbe ọgwụgwọ gasịrị, a na-ewepụ mandrel ahụ na ọkpọkọ fiberglass.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.