- 08

- Feb

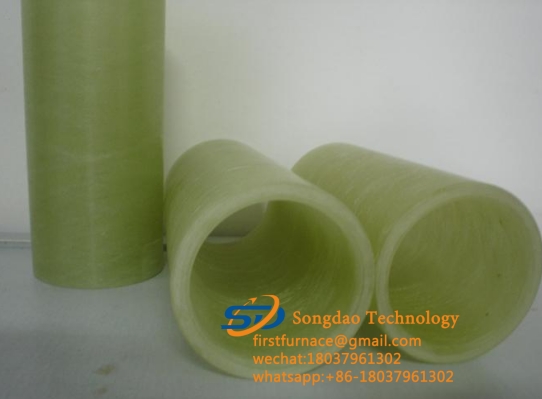

Farsamada Wax-soo-saarka iyo Horumarinta iyo Codsiga Tuubbada Fiberglass-ka

Farsamada Wax-soo-saarka iyo Horumarinta iyo Codsiga Tuubbada Fiberglass-ka

Waxaa jira saddex nooc oo waaweyn tube fiber galaas production processes: reciprocating filament winding process, continuous filament winding process and centrifugal casting process.

Habka dabaysha Fiilada isku-noqoshada ah (oo ka tirsan habka dhererka go’an): Habkan, haanta wax-ku-daridda waxay ku celinaysaa mandrel wareegta, iyo fiilooyinka muraayadda fiber-ka dheer ayaa la dhigayaa xagal gaar ah oo la xidhiidha dhidibka mandrel, iyo xagasha kaalmaynta. (ie. xagasha dabaysha) waxa lagu maamulaa saamiga xawaaraha dhaqaaqa haanta quusinta iyo xawaaraha wareega ee mandrel, iyo dhaqdhaqaaqa tarjumaada haanta quusinta waxa gacanta ku haya kontoroolka kombayuutarka ee elektiroonigga ah. Tirada lakabyada dabaysha ayaa si tartiib tartiib ah loo kordhiyaa ilaa la gaaro dhumucda derbiga ee la qorsheeyay. Ka dib marka dabaysha la dhammeeyo, xabagta ku jirta maqaalka si weyn ayaa loo daweeyaa. Ka dib markii la daweeyo, mandrel waxaa laga saaray tuubada fiberglass ah.

Continuous filament winding process (belonging to continuous method): The process is that the tube passes through a feeding station that supplies resin pre-impregnated roving, chopped glass fiber reinforced plastic fiber and resin sand mixture in motion, and the tube is continuously advancing in the core mold. made in.

Centrifugal casting process (belonging to the fixed-length method): In this process, the cut glass fiber reinforced material and sand are fed into a steel mold fixed on the bearing, and the unsaturated resin with catalyst is injected into one end of the steel mold to make the steel mold. It impregnates the reinforcing material. Under the action of centrifugal force, the resin replaces the air in the fibers and fillers, thereby producing a dense composite material without pores. Due to the action of centrifugal force, the inner wall of the tube forms a smooth and clean resin-rich inner surface layer. Cures at higher temperatures. The pipe made by this method is also called glass fiber reinforced plastic sand pipe.